Yes, you can Use Water Based Ink to Print on 50 50 Blends, but the result may vary. For optimal results, pre-treatment and proper curing processes are essential.

Water-based inks have gained popularity in the textile printing industry for their soft hand feel and eco-friendliness. This preference aligns with the increasing demand for sustainable fashion and environmentally conscious production practices.

As brands and consumers seek more earth-friendly apparel options, printers are adapting to techniques that accommodate a variety of fabric blends, including the common 50/50 cotton-polyester mix.

While water-based inks can be challenging to work with on these blended fabrics, advances in ink formulas and printing technology have made it a viable option.

Experienced printers know that achieving a high-quality print involves careful consideration of ink consistency, fabric type, and the correct application and drying techniques.

It ensures durability and colorfastness. As the industry continues to evolve, the interplay between material innovations and printing methodologies underscores the importance of skilled craftsmanship in the age of fast fashion.

Water-Based Ink And 50/50 Blends: Compatibility

Choosing the right ink for fabric printing can be a game-changer for the quality and durability of the print. Many wonder about water-based inks and their compatibility with 50/50 blend fabrics. This section digs into how well water-based inks adhere to these popular materials.

Attributes Of Water Based Inks

- Eco-friendly: Water-based inks contain fewer harmful chemicals compared to plastisol inks.

- Soft hand feel: They leave a softer print on the fabric, making it more comfortable to wear.

- Vibrant colors: These inks are known for producing bright, vivid prints.

- Heat curing: Water-based inks need to be heat-set for optimal durability.

Characteristics Of 50/50 Blend Fabrics

A 50/50 blend fabric combines cotton and synthetic fibers, typically polyester. This blend creates a material that balances the benefits of both types of fibers.

| Cotton | Polyester |

|---|---|

| Comfortable and breathable | Durable and wrinkle-resistant |

| Natural fiber | Quick-drying |

Such fabrics offer a unique challenge for water-based ink due to the synthetic component, which is less absorbent than cotton. The ink may not adhere as well to the polyester fibers, which affects print longevity and vibrancy.

Benefits Of Water Based Ink In Fabric Printing

In the world of fabric printing, choosing the right ink is crucial. Water-based ink offers unique advantages, especially when printing on 50/50 blends.

As businesses and consumers shift their focus to sustainable options, water-based inks emerge as the ideal choice. Adopt the benefits of using this eco-friendly ally in the textile industry.

Eco-friendly Qualities

Water-based inks are gaining popularity for their minimal environmental impact. They contain fewer harmful chemicals than traditional plastisol inks.

This means safer handling and less pollution. Biodegradability makes them a friend to the earth. They are easy to clean up, reducing water contamination.

- No toxic chemicals

- Lower carbon footprint

- Reduced waste

Soft Hand Feel And Comfort

Comfort is key in clothing. Water-based inks merge with the fabric, creating a soft touch. This results in a breathable print, perfect for 50/50 blends. Your print feels light, enhancing wearability. This makes tees printed with water-based ink a joy to wear all day.

| Printing Quality | Comfort Level |

|---|---|

| Soft print | High |

| Breathable | Light |

Challenges Of Printing On Mixed Fibers

Starting the venture of printing on 50/50 blends presents its unique set of challenges. A mix of cotton and synthetic fibers, these blends demand specific care in the printing process.

Two prominent hurdles stand out: ink absorption issues and durability concerns with water-based inks. Learning to navigate these challenges is important for high-quality, long-lasting prints.

Ink Absorption Issues

The inconsistency of fiber makeup in a 50/50 blend can lead to uneven ink absorption. Cotton fibers, being natural, absorb water-based ink differently compared to synthetic fibers. This can result in:

- Spotty prints with patchy areas

- Muted colors where the ink fails to latch on fully

- Varying quality across different batches of the same fabric

Pre-treatment of fabrics and careful curing processes are necessary to improve ink absorption and achieve a more uniform look.

Durability Concerns

Durability is a vital factor when considering water-based inks for mixed fibers. 50/50 blends pose a greater challenge in this world. Here’s why:

- Water-based inks can wash out quicker on synthetic fibers

- The lifespan of the print may be reduced significantly

- Cracking and fading can occur after repeated washing cycles

To combat these issues, selecting high-quality inks and optimizing the heat-setting phase are vital steps to increase the print’s life.

Prepping 50/50 Blends For Printing

Prepping 50/50 Blends for Printing stands is important for achieving a high-quality print finish. These fabrics, often a mix of cotton and polyester, require special attention to ensure that water-based inks adhere properly and the print maintains its integrity through washes. Let’s detail the processes necessary to prepare these blends for the best printing outcomes.

Pre-treatment Processes

Before printing, 50/50 blends demand a pre-treatment to improve ink adhesion. This step helps to prevent fading and ensures the colors stay vibrant. The following list presents the key steps in the pre-treatment process:

- Cleaning: Fabric surfaces must be free from oils, dust, and loose fibers.

- Drying: The material should be completely dry to ensure even absorption.

Optimizing Fabric For Ink Adhesion

To optimize the fabric’s ability to hold onto the water-based ink, different methods can be applied:

| Method | Benefit |

|---|---|

| Heat Pressing | Flatten fibers for a smoother print surface. |

| Binding Agent Application | Creates an adhesive layer for the ink. |

Correctly prepping a 50/50 fabric blend can make all the difference in print longevity and quality. These steps are essential for anyone aiming to produce professional-level printed materials.

Printing Techniques For Mixed Fabrics

Starting on the journey of printing on 50/50 blends calls for specific techniques. These fabrics merge the qualities of cotton and polyester. Navigating their complexities can be tricky. To achieve vivid prints while maintaining fabric integrity, we employ particular methods.

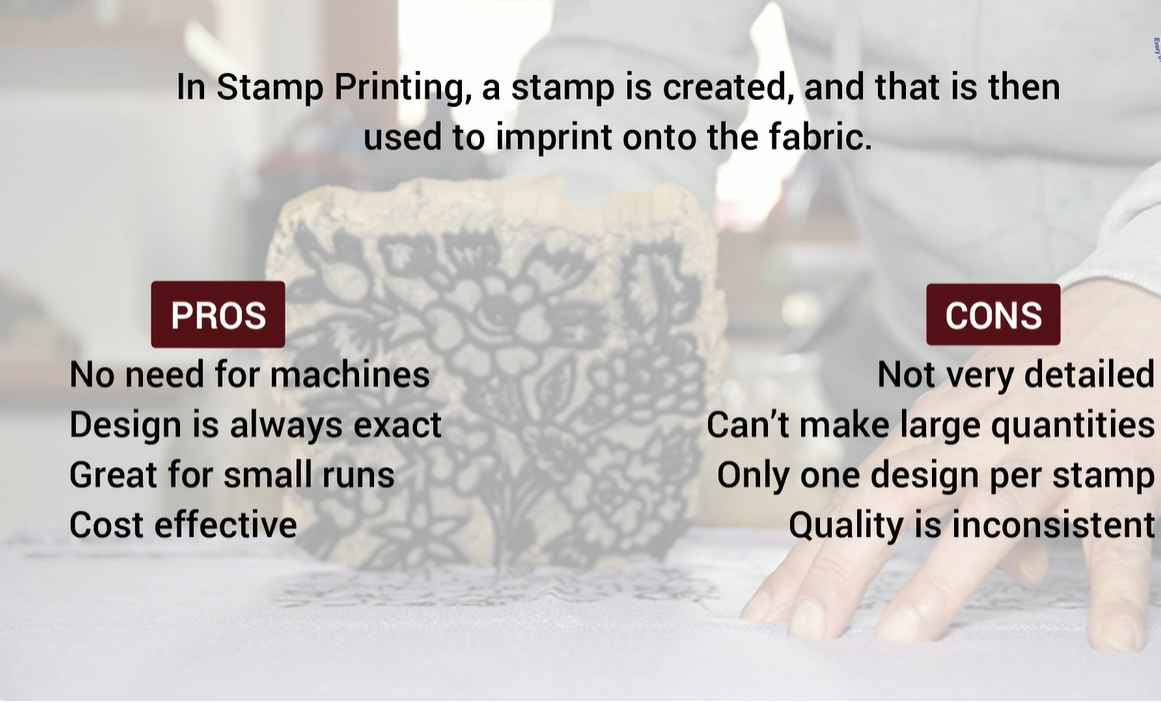

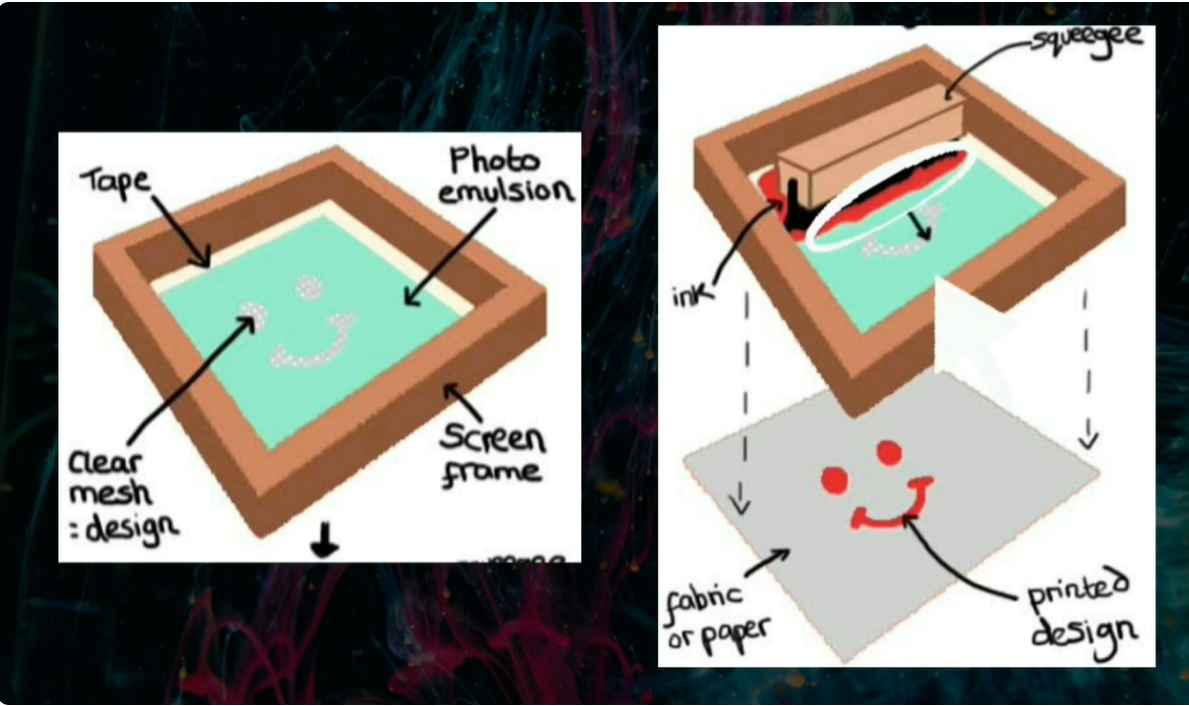

Screen Printing Adjustments

Screen printing on a 50/50 blend often demands finesse. Here’s a bulletproof plan:

- Mesh count matters: Opt for a higher mesh count to apply thinner ink layers.

- Off-contact printing: Ensure the screen lightly touches the fabric for a clean print.

- Reduce bleed: Apply a bleed blocker base to prevent dye migration.

- Ink consistency: Water-based inks should be smooth, but not too runny.

Expert tips: Test print on scrap fabric. Monitor pressure and angle consistency. Adapting screen printing to 50/50 blends can yield stunning results with practice.

Curing Methods For Longevity

Proper curing of water-based inks ensures prints live a long life. Let’s focus on making those prints last.

- Drying temperature: Keep it between 320°F to 330°F (160°C to 165°C).

- Drying time: Duration can vary from 90 seconds to 3 minutes, depending on the ink and fabric.

- Airflow is crucial: Good ventilation helps ink set without scorching the fabric.

| Step | Action | Purpose |

|---|---|---|

| 1 | Preheat the garment | Remove moisture to prime for printing |

| 2 | Apply water-based ink | Print while maintaining fabric texture |

| 3 | Cure the print | Secure the design for durability |

Remember to test the cure! Use a stretch test or a wash test. This ensures your print withstands the hurdles of everyday wear.

Ensuring Quality And Washfastness

What happens when water-based ink meets a 50/50 blend fabric? You want a print that lasts through washes and wears. Achieving this requires mastering how to maintain the ink’s integrity on the fabric. Let’s dig into the specifics of quality and wash fastness with water-based inks.

Testing Ink And Fabric Interaction

Before mass printing, a important step is testing. How will the ink adhere to the blend? Here’s a simple guide:

- Apply a small ink amount to the fabric.

- Heat-set the sample as per the ink’s specification.

- Wash the sample multiple times.

- Assess the print for any fading or quality changes.

This process safeguards against future issues, ensuring the print stays vibrant and durable.

Tips For Maintaining Print Quality

Preserving the brilliance of your print necessitates proper care. Here are tips to help:

- Follow the ink manufacturer’s setting instructions. This step is non-negotiable.

- Use a heat press for even temperature distribution.

- Wash printed garments inside out, with cold water.

- Avoid harsh chemicals and bleach during washing.

- Air-dry the garments rather than using high heat.

With these guidelines, your printed 50/50 blends will stay sharp and vibrant wash after wash.

Case Studies: Water-Based Ink On 50/50 Blends

Screen printers often ask about using water-based ink on various fabrics. 50/50 blends, a mix of cotton and polyester, are popular for their comfort and durability. But, there’s a question: does water-based ink work well on them? Let’s dig into real-life cases to answer this.

Success Stories From The Industry

Many printers have adopted water-based ink for its eco-friendliness and soft feel. Even on 50/50 blends, the results can be impressive.

- Brand A achieved a soft-hand feel on their vintage clothing line.

- Brand B optimized durability in its sportswear collection.

- Small shop C reduced its carbon footprint and still maintained high print quality.

These successes show that with the right technique, water-based ink and 50/50 blends are a perfect match.

Learning From Common Mistakes

But not all attempts turn out well. Mastering the pitfalls helps printers improve their results.

| Mistake | Lesson Learned |

|---|---|

| Inadequate curing | Ensure proper curing time and temperature for ink to set. |

| Too much ink | Balance ink volume for a crisp, clear print on blended fabrics. |

| Incorrect mesh count | Select the right screen mesh count for ink consistency and detail. |

By studying these mistakes, printers can steer clear of them and achieve better outcomes with water-based inks on 50/50 blends.

Choosing The Right Inks And Materials

Printing on fabric blends demands a careful selection of inks and materials. The outcome hinges on compatibility and finish. This guide digs into making informed choices.

Selecting Superior Water-Based Inks

Water-based inks offer a soft hand feel on fabrics. Key traits for choosing these inks include:

- Eco-friendliness: They are often more sustainable than other inks.

- Vibrancy: Top-quality water-based inks deliver bright colors.

- Printability: Look for inks that can easily pass through mesh on screens.

- Cure times: They should have practical cure times for fast production.

Factors In Picking The Best 50/50 Blends

Half cotton, half synthetic, 50/50 blends are popular. Remember:

| Fabric Quality | Print Compatibility | Durability |

|---|---|---|

| Choose high-grade materials for a premium feel. | Ensure the blend supports water-based ink. | Seek fabrics that withstand multiple washes. |

Check the smoothness of the fabric. It affects ink adherence.

Pushing The Boundaries: Innovative Practices

The world of fabric printing is continuously evolving. Traditional methods are giving way to new techniques. These techniques promise more versatility and better quality. One question on many printers’ minds is about using water-based ink on 50/50 blends. Can it work? We’re about to find that in detail.

Recent Advances In Water-Based Printing

Water-based inks have long been praised for their eco-friendliness and soft hand feel. They weren’t always the first choice for 50/50 blends, which combine cotton and polyester. But innovative solutions have changed that. Here’s what’s new:

- High-Solids Water-Based Inks: These new inks spread smoothly on 50/50 blends. They provide vivid colors without heavy layering.

- Low-Cure Additives: These help inks dry faster. They make printing on sensitive fabrics possible without scorching.

- Hybrid Systems: Combining water-based and discharge inks leads to stunning prints on 50/50 blends.

Future Trends In Mixed Fabric Printing

Looking forward, the technology for printing on mixed fabrics like 50/50 blends is only getting better. Here are a few trends to watch:

- Water-Based Polyester Inks: New inks are in development. They stick better to polyester, making them ideal for 50/50 blends.

- Digital Hybrid Printing: This combines screen printing with digital processes. It allows more flexibility in designs.

- Sustainability: There’s a focus on reducing waste and pollution. So, water-based inks are improving in this area.

Frequently Asked Questions Of Can You Use Water Based Ink to Print on 50 50 Blends

What Do You Use Water-Based Ink For?

Water-based ink is primarily used for screen printing on textiles, producing soft, breathable prints ideal for comfortable clothing. It’s also favored for eco-friendly printing practices due to its low toxicity and ease of cleanup.

Can You Screen Print On 50% Cotton and 50% Polyester?

Yes, you can screen print on a fabric blend of 50% cotton and 50% polyester. Both materials take screen printing well, offering durability and quality in the print.

Can I Use Water-Based Ink On Polyester?

Water-based ink is not recommended for polyester due to the fabric’s hydrophobic nature, which causes poor adhesion and uneven curing. For best results, use specially formulated inks designed for polyester.

Can You Use Water-Based Ink On Dark Shirts?

Using water-based inks on dark shirts is not optimal as the ink can appear faded. It’s best to use opaque or discharge inks for vibrant prints on dark fabrics.

Conclusion

Exploring the versatility of water-based inks is enlightening. Yes, 50/50 blends can adopt such eco-friendly inks, ensuring vibrant designs with reduced environmental impact. Keep fabric composition and proper technique in mind for optimum results. Unlock the full potential of your fabric prints by mastering water-based ink usage on diverse materials.

Choose sustainability, choose quality printing—venture confidently into eco-conscious textile printing.