Sublimate on Cardstock is not typically possible, as it lacks the required polyester coating. Cardstock generally doesn’t withstand the heat required for sublimation.

Sublimating designs onto materials has become a preferred method for creating vibrant, long-lasting prints.

One might wonder whether this technique extends to cardstock, a common medium for crafters and businesses alike.

Unfortunately, sublimation requires a special polyester coating to transfer and bond the ink to the substrate, which standard cardstock lacks.

Additionally, cardstock can’t endure the high heat needed for the sublimation process, leading to potential damage or warping.

For those looking to print on cardstock, alternative methods such as inkjet or laser printing are more suitable and will yield better results.

Understanding these limitations ensures that you choose the right materials for your printing projects, avoiding wasted time and resources on incompatible combinations.

The Basics Of Sublimation On Cardstock

Exploring the creative possibilities of sublimation printing brings us to an exciting question: Can you sublimate on cardstock? This technique often used on fabrics begs the experiment on other substrates. Before diving in, let’s understand the basics of sublimation on cardstock.

Sublimation Process Simplified

Sublimation is a magic-like process where a solid turns into a gas without becoming liquid. It needs three things: sublimation ink, heat, and pressure. Here’s a simple breakdown:

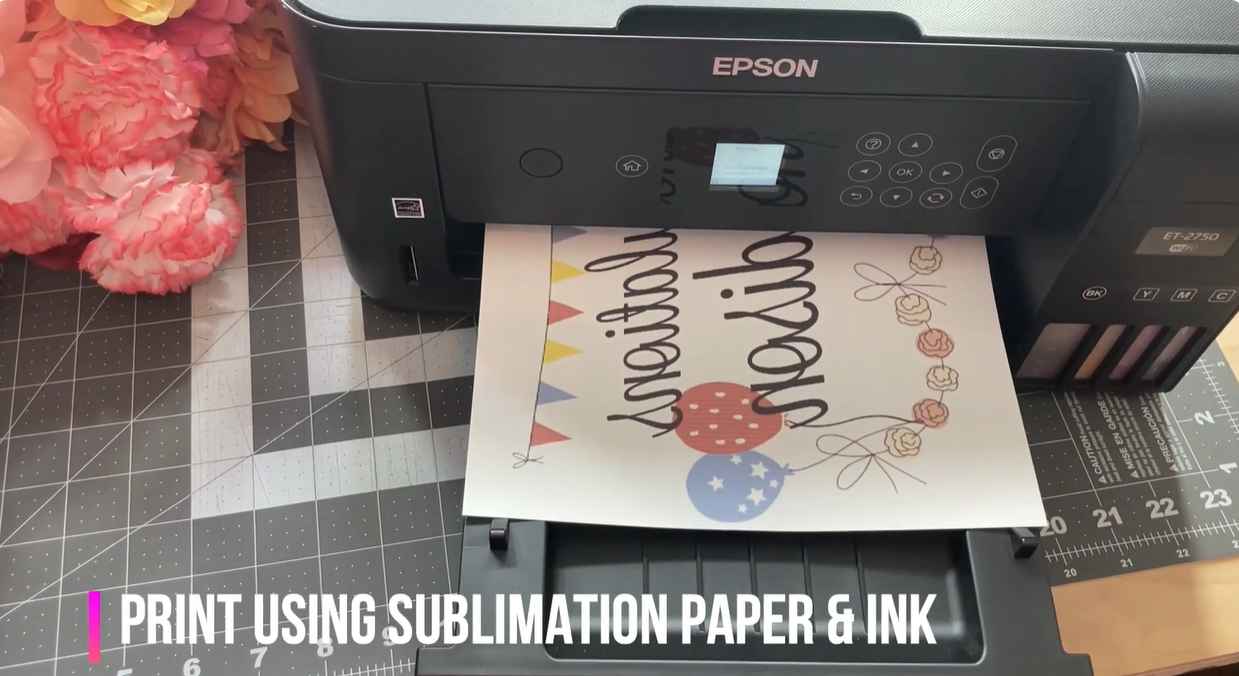

- Print your design with sublimation ink on special paper.

- Place the print onto the cardstock.

- Use a heat press to apply heat and pressure.

- The ink turns into gas and transfers onto the cardstock.

- Remove the paper, and your design lives on the cardstock!

Why Cardstock Isn’t Just Regular Paper

Cardstock is no ordinary paper. It’s thicker and more durable. Its surface is key to sublimation success. The right cardstock can mean the difference between vivid, lasting images and dull, faint ones.

| Feature | Benefit |

|---|---|

| Density | Holds designs better than thin paper. |

| Surface Coating | Allows ink to sit and transfer cleanly. |

| Heat Resistance | Withstands sublimation temperatures without warping. |

Remember, not all cardstock is sublimation-ready. Pick the type that’s coated for this purpose.

Materials And Tools For Sublimating On Cardstock

Creating vibrant, high-quality prints on cardstock through sublimation is an exciting project for crafters and professionals alike.

It involves a combination of the right type of cardstock and specific tools to achieve stunning results. Understanding which materials and tools to use is crucial.

Choosing The Right Cardstock

Selecting the appropriate cardstock is a pivotal step in the sublimation process.

- Sublimation-friendly: Look for cardstock labeled as compatible with sublimation dyes.

- Coated surface: This ensures the dye sticks and doesn’t bleed.

- Thickness: Choose a cardstock that can handle the heat without warping.

| Cardstock Attribute | Why It’s Important |

|---|---|

| Sublimation-Ready | Prevents ink from fading and ensures a sharp print. |

| Coating | Enables even and smooth color transfer. |

| Weight | Contributes to the cardstock’s durability during heat pressing. |

Essential Equipment For Sublimation

Having the correct equipment on hand is non-negotiable for successfully sublimating onto cardstock.

- Sublimation Printer: This specialized printer uses sublimation inks.

- Heat Press: Required to transfer the dye onto the cardstock.

- Sublimation Ink: Ink that turns into gas when heated and bonds with the paper.

- Heat-Resistant Tape: Keeps the paper in place during pressing.

Tip: Ensure your heat press can accommodate the thickness of your cardstock. Adequate pressure throughout the pressing process is critical to prevent ghosting and ensure sharp, vibrant prints.

Armed with the proper materials and tools, you’re now ready to embark on your sublimation journey with cardstock. Embrace the process, and look forward to the beautiful, professional-quality prints that await you.

Prepping Cardstock For Sublimation

Sublimating on cardstock may sound tricky. But, with the right techniques, striking results are possible. Begin with high-quality cardstock designed for ink absorption. This ensures vibrant and lasting colors. Prepping cardstock correctly is key to sublimation success. Let’s dive into how you can do this.

Surface Treatment And Preparations

Start with a clean workspace. Dust or debris can affect the sublimation process. Make sure the cardstock is flat. Any wrinkles could lead to imperfections. Here’s how to treat the cardstock surface:

- Choose the right type of cardstock. Look for one compatible with dye-sublimation inks.

- Clean the surface. Use a lint-free cloth to remove any dust.

- Apply a sublimation coating if your cardstock isn’t pre-treated. This helps the ink to bond.

Use heat-resistant tape to position your design. This stops the paper from moving during the sublimation process.

Tips To Avoid Common Mistakes

Mistakes can happen. But, they’re easy to avoid with these tips:

- Test print first. This saves materials and time.

- Check printer settings. Match them to the paper type for best results.

- Use the right ink. Sublimation ink is different from regular ink.

- Be mindful of time and temperature. Follow specific guidelines for your cardstock.

Always use a protective layer like butcher paper between the cardstock and the press. This prevents ink from bleeding through.

Remember, patience and attention to detail go a long way. Happy crafting!

Sublimation Techniques: From Theory To Practice

Stepping into the world of sublimation might seem daunting. Yet with creativity, you can transform ordinary items into bespoke pieces. Cardstock is not a common choice for sublimation, but it’s possible. This post delves into doing it right.

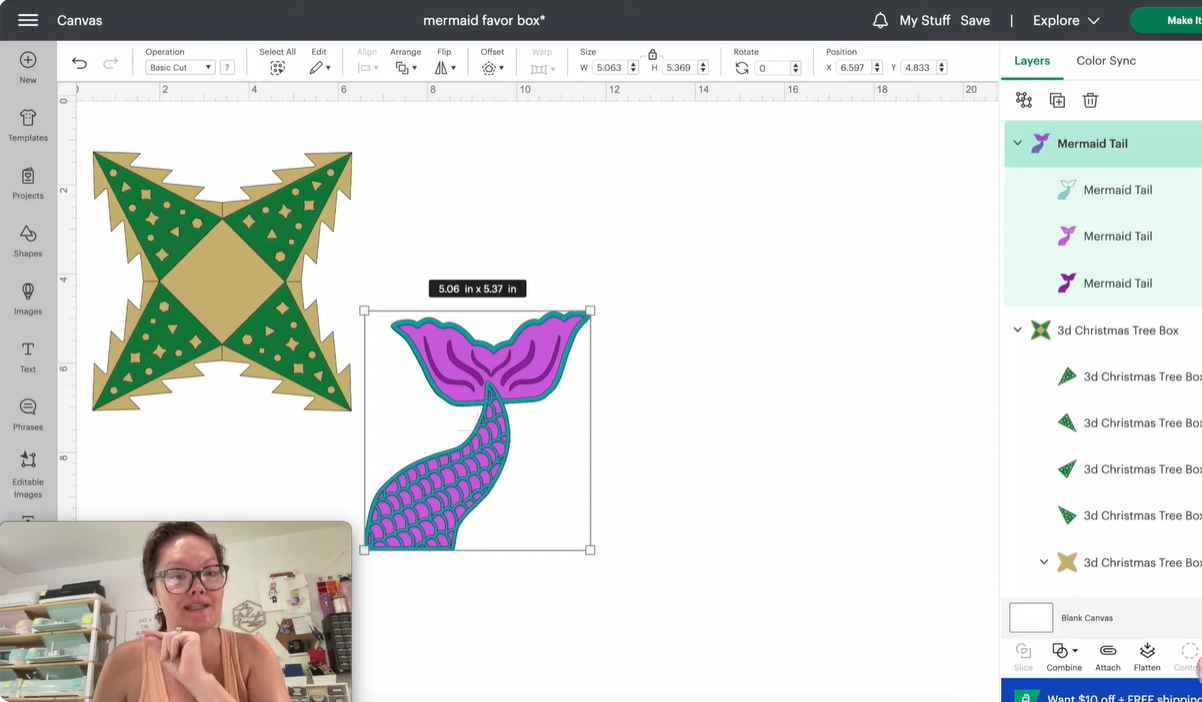

Step-by-step Sublimation Guide

Sublimation on cardstock needs a careful approach to avoid burning or warping. Here’s your guide:

- Select high-quality sublimation ink and paper.

- Print your design on sublimation paper with a compatible printer.

- Trim the paper to fit the cardstock, if needed.

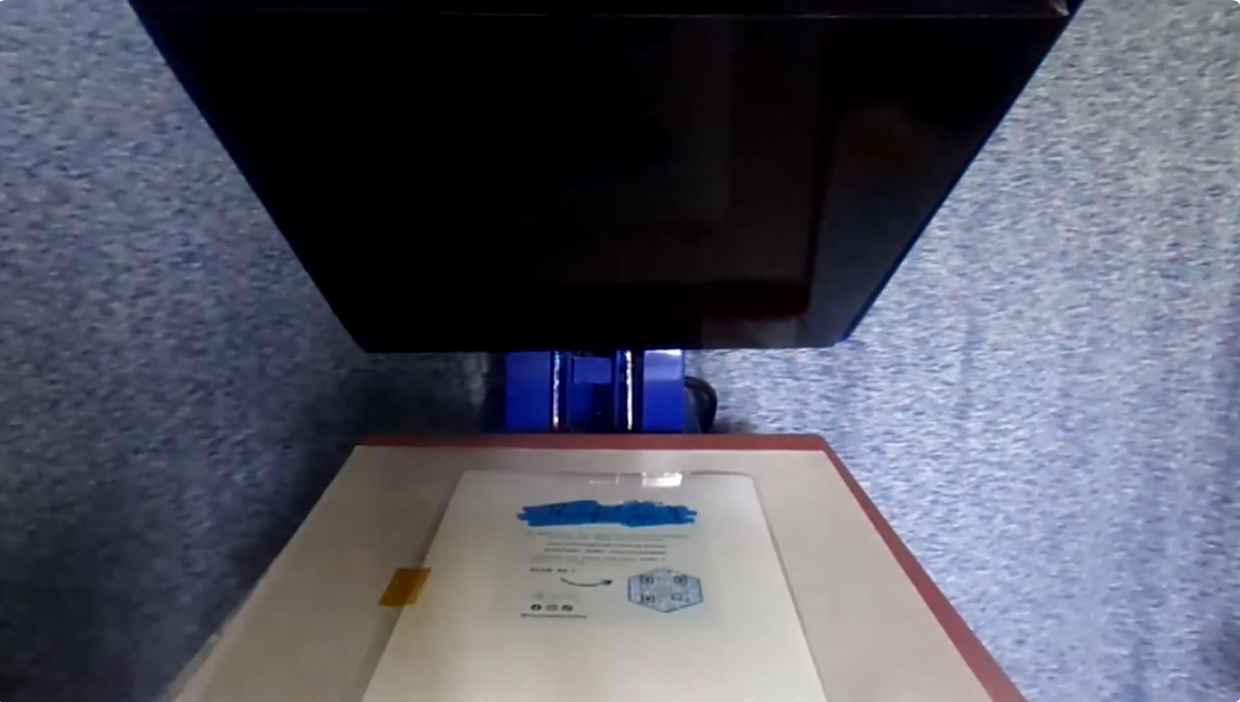

- Secure the paper to the cardstock using heat-resistant tape.

- Place it in the heat press.

- Press with appropriate settings (as discussed next).

- Peel away the paper once cooled.

- Admire your vibrant, durable design on cardstock!

Adjusting Heat Press Settings For Cardstock

The cardstock is delicate. You must adjust your heat press settings carefully:

| Setting | Cardstock Adjustment |

|---|---|

| Temperature | Lower than fabric, around 350°F (177°C) |

| Time | Shorter press time, around 10-15 seconds |

| Pressure | Light to medium, to prevent warping |

Always test these settings on a piece of scrap before the final attempt. This ensures perfect sublimation on cardstock.

Creative Applications For Sublimated Cardstock

Sublimating on cardstock opens a world of creative possibilities for crafting enthusiasts and decorators alike. This technique allows vibrant designs to transfer onto cardstock, bringing color and personal flair to various projects. From custom greeting cards to unique home decor items, the applications of sublimated cardstock are far-reaching and exciting.

Crafting Personalized Greeting Cards

Personal touches make greeting cards stand out. With sublimation, every card becomes a canvas for individual creativity. Here’s how:

- Birthday wishes with favorite colors and images.

- Anniversary cards featuring memorable photos.

- Custom holiday greetings with unique designs.

Create a cardstock sublimation series for a year-round collection. This way, a thoughtful, custom-made card is always at hand.

Innovative Uses In Home Decor

Sublimation on cardstock extends beyond paper goods. Transform living spaces with these inventive ideas:

| Decor Item | Idea |

|---|---|

| Wall Art | Display a series of sublimated prints with cohesive themes. |

| Coasters | Sublimate unique patterns onto cardstock, then seal for durability. |

| Gift Tags | Attach personalized tags to presents, adding a charming touch. |

For a bolder statement, combine sublimated cardstock with other materials to craft mixed-media pieces. This approach brings texture and depth to your decor.

Troubleshooting Common Cardstock Sublimation Issues

Running into snags with cardstock sublimation? Don’t fret! This section delves into common hitches and how to fix them, ensuring your sublimation prints turn out perfect on cardstock each time.

Handling Color Bleeding And Fading

Color bleeding and fading can be a real pain in cardstock sublimation. But tackle these issues the right way, and you’ll see those vibrant colors stay put. Here’s what to do:

- Temperature check: Make sure your heat press is at the right temp. Too hot, and the ink goes rogue.

- Timing is everything: Don’t leave your cardstock in the press too long. Hit that sweet spot of time for crisp images.

- Stay cool: Let your print cool down before you touch it. Patience keeps colors in their place.

Addressing Adhesion Challenges

Adhesion issues could make your cardstock sublimation project less sticky than you’d like. Stick with these tips, though, and you’ll be onto a winner:

| Problem | Solution |

|---|---|

| Ink not sticking | Match your cardstock to your ink. Some cardstock is picky about mates. |

| Peeling design | Use heat-resistant tape. It keeps your design in place under pressure. |

| Faint prints | Check your ink supply. A full cartridge means full-on color. |

Preserving And Protecting Your Sublimated Creations

Creating vibrant prints with sublimation on cardstock is just the first step. Ensuring your artwork stands the test of time is vital. Let’s explore how to keep your sublimated cardstock colorful and crisp.

Sealing Techniques For Longevity

Seal your sublimated cardstock to protect it from fading, scratches, and moisture. A clear spray sealant offers a quick-drying solution. Apply thin, even coats. This method prevents color run and enhances durability. Lamination is another option. It shields the ink from external elements. Always allow your sublimation print to dry completely before sealing.

- Clear-coating sprays provide UV protection.

- Lamination sheets add a protective layer.

Storage Tips For Sublimated Cardstock

How you store your sublimated cardstock matters. Keep your creations looking fresh with the right storage. Avoid places with direct sunlight. Use acid-free folders or sleeves for extra protection. Maintain a stable environment: watch temperature and humidity levels.

- Keep out of direct sunlight to prevent fading.

- Use acid-free storage to stop yellowing.

- Control environment for optimal preservation.

Follow these storage tips:

| Storage Method | Benefit |

|---|---|

| Acid-free sleeves | Prevents yellowing |

| Dark, cool place | Reduces risk of fading |

| Constant temperature | Avoids ink migration |

Remember, proper sealing and storage ensures long-lasting brilliance for your sublimated cardstock treasures.

Frequently Asked Questions On Can You Sublimate On Cardstock? (solved)

What Kind Of Cardstock Can I Sublimate On?

You can sublimate on specially coated cardstock designed for dye-sublimation printing. Standard cardstock won’t work as it lacks the necessary coating to transfer and retain the sublimation ink.

How Long Do You Sublimate On Cardstock?

Sublimate on cardstock for about 60 to 120 seconds at 400°F, but always check the specific paper’s instructions for optimal results. Adjust time for thickness and desired effect.

What Materials Can You Not Sublimate On?

Sublimation does not work on materials that lack a polymer coating or are not polyester-based. Examples include 100% cotton fabric, natural fibers, and non-coated metals.

Can You Sublimation Print On Cardboard?

Yes, you can sublimation print on cardboard if it has a special polymer coating to accept the dye. Regular cardboard without this coating will not work effectively for sublimation printing. Always choose coated cardboard for best results.

Conclusion

Wrapping up, the question of sublimating on cardstock is no longer a mystery. With the right tools and techniques, creating vibrant, lasting prints on cardstock can be achieved. Remember, selecting compatible ink and cardstock, along with proper heat application, is crucial.

Dive into your next project with confidence, and let your creativity shine on every page!