Yes, you should mirror sublimation images before printing. This ensures the final product displays the design correctly.

Creating quality sublimation prints involves a specific process that transfers a design from paper to fabric or another medium. Mirroring images is a essential step that allows for the correct orientation once the heat transfer process is complete. Ignoring this step can result in products with designs that are backward or unreadable, compromising the quality of the final item.

This technique is particularly important when dealing with text or logos that must be read correctly on the final product. For those new to sublimation printing, mastering this step is essential to producing professional-looking merchandise or customized items that meet customer expectations. Always remember to flip the image horizontally before printing for successful sublimation projects.

The Concept Of Sublimation Printing

In the world of custom printing, sublimation offers a method like no other. It allows full-color, high-definition images to imprint on a variety of surfaces. Let’s dig deep into what sublimation printing is and why image orientation matters.

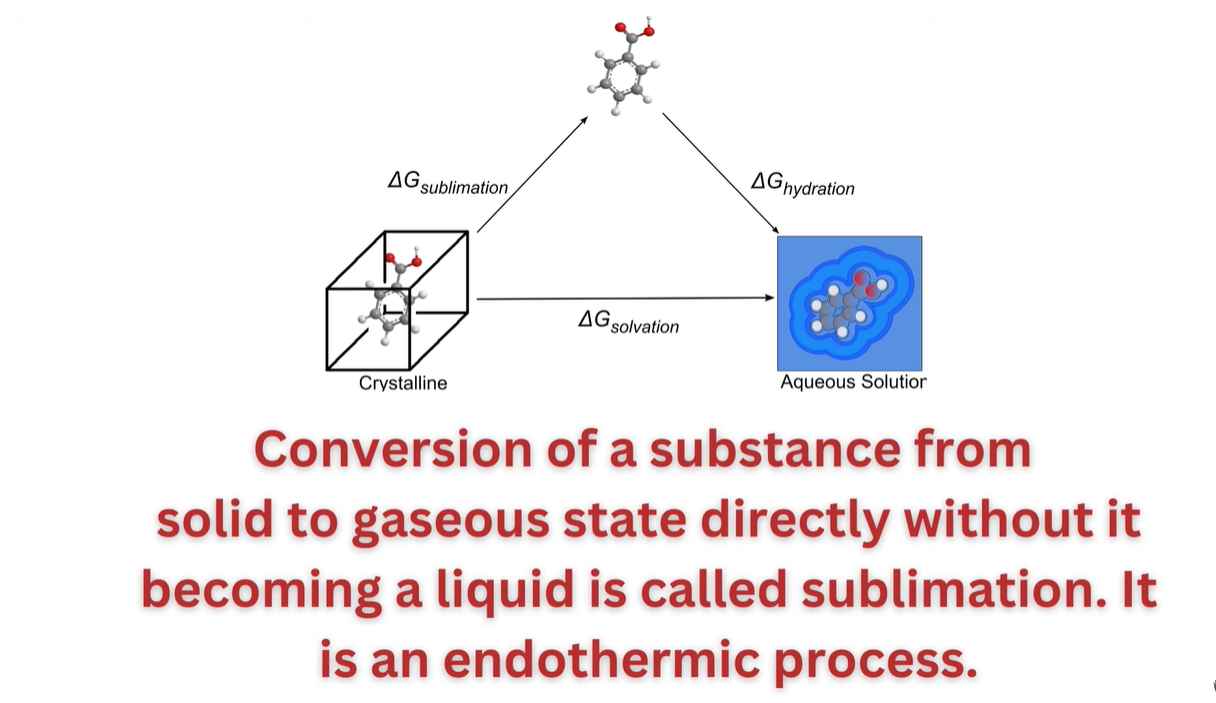

Sublimation Defined

Sublimation printing transforms designs into vibrant, permanent prints. The process uses heat to turn dye into gas, binding it to the material. No ink or liquid stage involved, the result? Durable, eye-popping graphics on your items.

Importance Of Image Orientation

The correct orientation ensures your prints come out looking perfect. Mirror images are critical in sublimation. They appear reversed when printed but once transferred, they display correctly. This step is important for lettering and faces to avoid any awkward mishaps.

Why Mirroring Matters In Sublimation

Sublimation printing transforms ideas into vibrant reality. The process merges ink and material, becoming one. Yet, one step often missed is mirroring images. Mirrored images ensure designs appear correctly when transferred. Picture this: texts read backward, faces flip side, chaos ensues. The need for mirroring in sublimation is clear.

The Science Behind Mirroring

In sublimation printing, designs flip during transfer. Mirroring corrects this flip. Think of it as a selfie mode for your prints. When heated, the sublimation ink turns to gas. This gas imprints on the material in reverse. Without mirroring, images would transfer the opposite of the intended design.

- Heat causes ink to gasify

- Ink bonds to material in mirror-image form

Common Mistakes In Sublimation

Skipping the mirroring step is a common error. Designs look great on screen but transfer incorrectly. Not just texts, but all elements need flipping. Avoiding these mistakes saves time, material, and frustration.

| Mistake | Impact |

|---|---|

| Text Not Mirrored | Text unreadable on the final product |

| Incorrect Image Orientation | The design appears backward or upside down |

| Forgetting to Test Print | Potential waste of materials |

To recap, mirroring images ensures design integrity once sublimated. Always check, mirror, and test. Perfect prints every time.

Preparing Images For Sublimation

Preparing Images for Sublimation is a crucial step in the creative process of transferring your unique designs onto a variety of substrates. The magic truly happens when your artwork gets reversed on one end and then perfectly aligns upon transfer. Let’s explore how to get your images ready for a flawless finish.

Choosing the Right Software

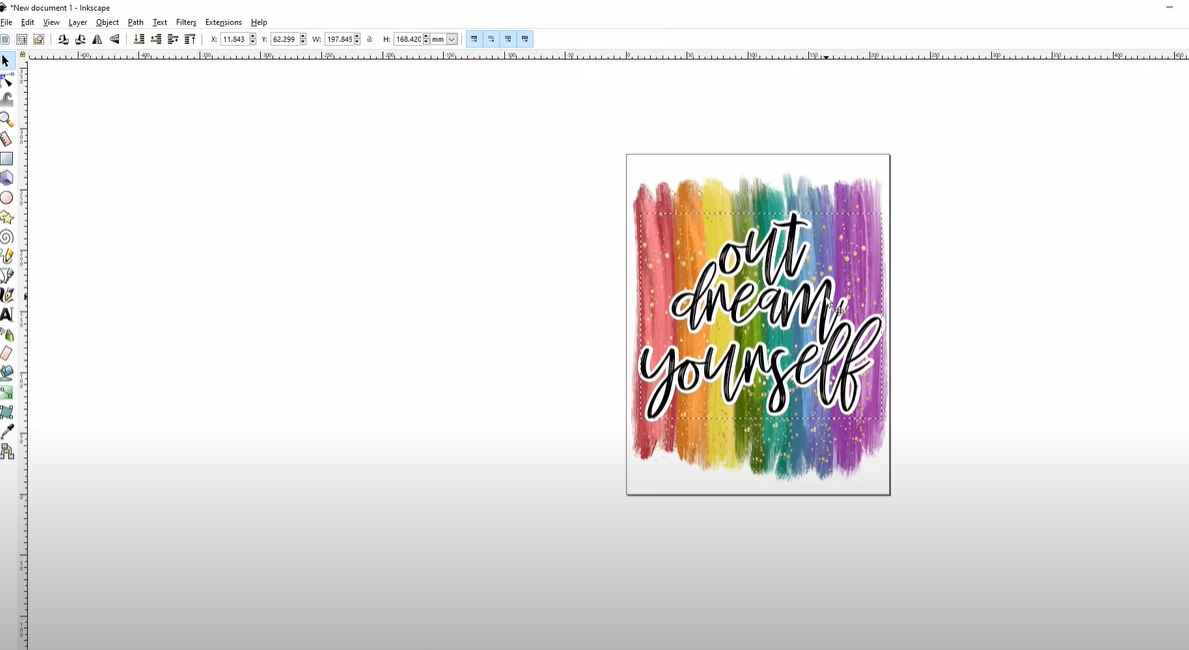

Choosing The Right Software

Success in sublimation begins with software selection. The right software makes all the difference. It should enable you to edit, flip, and print images effortlessly.

- Adobe Photoshop: Known for its advanced features and versatility.

- GIMP: A free alternative, suitable for basic to intermediate editing needs.

- CorelDRAW: Preferred by some for vector-based designs.

Select software that’s compatible with your printer and skills. It should support your creative process smoothly.

Step-by-Step Image Mirroring

Step-by-step Image Mirroring

Here’s how to mirror your images for sublimation:

- Open your image: Use your chosen software to load the design.

- Find the mirror option: Typically found under the ‘Edit’ or ‘Image’ menu.

- Apply the mirror effect: Click the mirror button to flip your image.

- Save your work: Keep the mirrored version for printing.

Printing the mirrored image transfers the design correctly onto your medium. Make sure your print settings are correct. Always run a test print before final production.

Technical Tools For Sublimation Success

For a thrilling adventure in sublimation printing, the right tech tools are must-haves. They make your design dreams come alive on a myriad of materials. Let’s dig into the instruments of creation that set you up for sublimation success.

Sublimation Printers And Presses

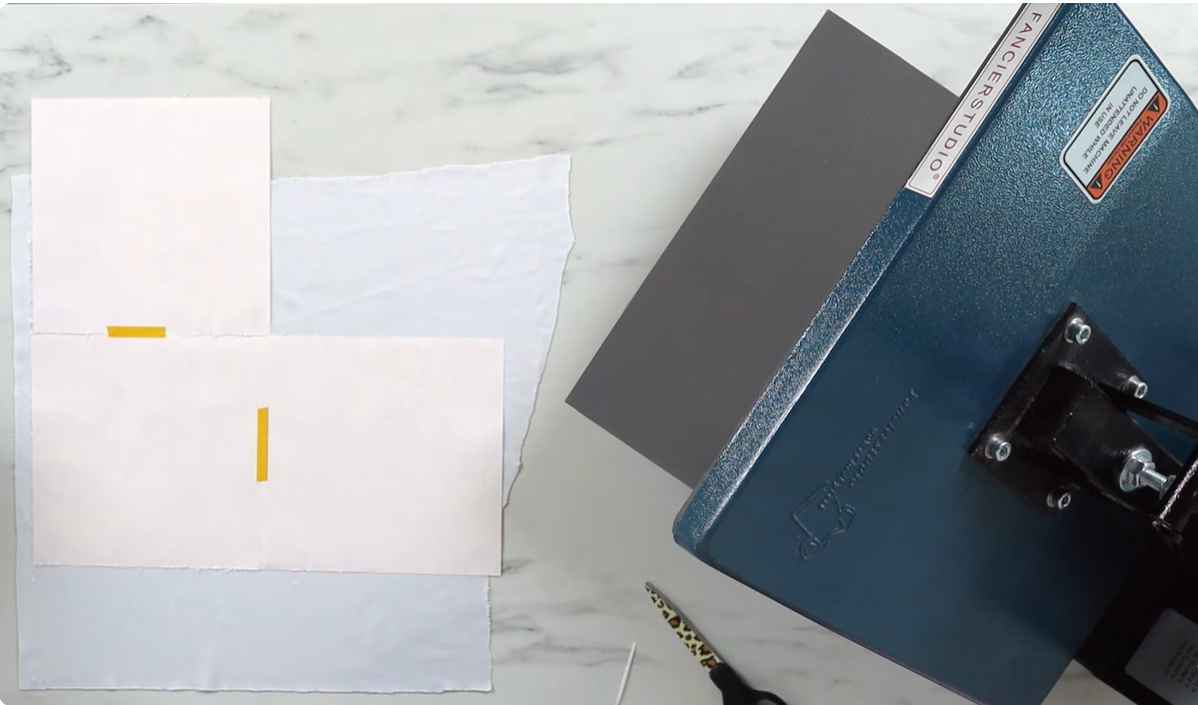

Every masterpiece starts with a blank canvas—in sublimation, that’s your sublimation printer and press. Think of them as the paintbrush and palette.

- Printers: A sublimation printer transforms digital art into transferable prints. These prints mirror your designs. Always mirror images before printing. This ensures designs look right after pressing.

- Presses: Heat presses transfer the magic to your material. Pick the right size and type for your project. It matters.

| Printer Feature | Press Type |

|---|---|

| Ink delivery precision | Flatbed press |

| Color Integrity | Mug press |

| High-resolution output | Cap press |

Essential Software Features

The right sublimation software brings ideas to life. It needs features tuned to your craft.

- Mirroring: The software should flip images easily. Your prints come out perfect after pressing.

- Color Management: Accurate colors are crucial. The software must match the screen and print colors.

- Format Support: It should handle various file types. Your creativity should not be limited.

The right print-ready software saves time. It makes printing painless. Invest in software that scales with your art.

Materials And Fabrics In Focus

The world of sublimation printing is intricate. The choice of materials and fabrics is important. It determines how well image mirroring works. Let’s deep dig into the best fabrics and materials for this process.

Best Fabrics For Image Transfer

Sublimation requires fabrics that respond well to heat and can bond with ink. Polyesters and polymer-coated items provide the best results. Here’s why:

- Polyester fabrics retain vibrant colors after transfer.

- High poly-blends offer good quality transfers with some cotton presence.

- Pre-treated fabrics ensure ink bonds and don’t wash out.

It’s key to pick the right fabric. This ensures your image looks sharp and stays that way.

How Material Types Affect Image Mirroring

| Material Type | Effect on Mirroring |

|---|---|

| Pure Polyester | Provides a clear, precise mirror effect. |

| Poly-Cotton Blends | The mirror effect may slightly dilute due to cotton. |

| Non-Coated Materials | May not mirror images effectively; ink cannot bond well. |

Select materials that enhance the mirroring process. This ensures your designs are reflected perfectly.

Troubleshooting Common Sublimation Issues

Sublimation printing is a popular method for transferring vivid, full-color images onto a variety of materials. Perfecting sublimation requires understanding both the process and potential problems. Recognizing common issues early on helps avoid costly mistakes and product waste. Here are solutions for two frequent sublimation challenges: image ghosting and incorrect color transfer.

Image GhostingImage Ghosting

Ghosting happens when the sublimation paper shifts during the transfer process. This double-image effect can ruin a project. To prevent ghosting:

- Secure the paper to the substrate using heat-resistant tape.

- Avoid lifting or moving the press before the cycle completes.

- Ensure even pressure throughout the heat press cycle.

For existing ghosting, adjust your technique before reprinting. Check that the substrate is flat and secure for the next press.

Incorrect Color TransferIncorrect Color Transfer

Colors can appear off due to several factors. To fix incorrect color transfer:

- Calibrate your printer regularly for color accuracy.

- Use the right sublimation ink and ICC profiles for precise color matching.

- Check the substrate’s quality as it influences color outcome.

If colors are still not correct, test with different settings or consult the printer’s manual. Quality substrates and a calibrated printer lead to better color transfers.

Expert Tips And Tricks

Welcome to our latest collection of Expert Tips and Tricks for mastering sublimation printing! This craft blends art with precision, and knowing the correct methods can make all the difference. Whether a hobbyist or a seasoned pro, these insights will elevate your sublimation game. Let’s dig into achieving the best print quality and keeping your equipment in top shape for years to come.

Achieving Optimal Print Quality

Sublimation printing is all about clarity and vibrancy. To ensure images pop, there’s a secret: mirror your images. Here’s why and how to do it right:

- Mirroring prevents text and designs from appearing backward.

- Use editing software to flip images horizontally before printing.

- Choose high-resolution pictures for a crisp, sharp finish.

- Test print on regular paper to save on sublimation ink and paper.

- Always use premium sublimation paper for ink-transfer efficiency.

Remember, colors appear differently post-transfer, so adjust your image settings to match your desired outcome.

For top-tier results, consider print settings and the type of substrate. Fabrics and hard surfaces might react differently to heat and pressure. Experiment with your heat press, adjusting time and temperature for the perfect transfer.

Maintaining Equipment For Longevity

Your sublimation printer and heat press are the backbones of your projects. Keep them running smoothly with these practices:

- Clean your printer’s ink heads regularly to avoid clogs.

- Update software and drivers for optimal printer performance.

- Use the recommended ink type and follow the manufacturer’s guidelines.

- Protect your heat press with non-stick sheets to prevent residue buildup.

- Inspect the heat press for consistent temperature distribution.

Proper cooling after use extends the life of your equipment. Additionally, store it in a dust-free environment and cover devices when not in use. This attention to maintenance will keep your tools in prime condition for countless projects.

Frequently Asked Questions Of Do You Mirror Sublimation Images

Do You Have To Mirror Sublimation For Tumblers?

Yes, you must mirror the image when preparing the design for sublimation on tumblers to ensure the graphic displays correctly after transfer.

Do You Mirror Sublimation Cricut?

Yes, you need to mirror your design in Cricut Design Space before printing for sublimation, ensuring the image transfers correctly onto your substrate.

How long do you press sublimation?

Suggests an inquiry into the optimal duration for applying sublimation, a process involving the transfer of a substance from a solid to a gas without passing through a liquid stage. This article may explore the critical time factors in achieving successful sublimation results, providing insights for those engaged in related applications or industries.

What image format for sublimation?

The choice of image format for sublimation is crucial, with popular options being PNG and TIFF. These formats support lossless compression, ensuring high-quality prints, while PNG also allows for transparent backgrounds, offering versatility in design for sublimation processes.

How Do You Flip An Image For Sublimation?

To flip an image for sublimation, open the image in a graphic design program and select the ‘Flip’ or ‘Mirror’ function, usually found under the ‘Image’ or ‘Edit’ menu. Save the mirrored version for sublimation printing.

What Is The Best Way To Print Sublimation Images?

To best print sublimation images, use a high-quality sublimation printer with suitable sublimation ink. Choose a specific sublimation paper for image transfer. Ensure your fabric or material is sublimation-ready, usually polyester or polymer-coated. Set the correct heat press temperature and time for optimal image transfer.

Conclusion

Wrapping up, and mastering the art of mirror imaging for sublimation is a game-changer. Adopt this technique ensures your custom prints transfer perfectly every time. Remember, flipping your artwork before printing is the secret to crisp, professional results on your sublimated items.

Get creative and happy transferring!