Black sublimation turns green primarily due to overheating during the printing process. Excess heat can cause black dye to break down, revealing underlying green tones.

Ever wondered, ‘Why is Black Sublimation Turning Green? Discover the Possibilities!’ Sublimation printing, a favored technique for transferring designs onto different materials, faces a common challenge in achieving the perfect black hue. The intricate dance of heat and time control becomes crucial in this process.

Crafters and printers often encounter the perplexing issue of black dye transforming into an unwanted green shade. This unexpected color shift signals that the sublimation ink may be overheating, leading to an alteration in the dye’s intended color.

Preventing this predicament requires meticulous temperature management. The key lies in striking the right balance to preserve the integrity of the black dye throughout the sublimation process.

The intricacies of sublimation demand a keen eye for detail, especially in regulating heat settings, to ensure the final product retains its intended hue.

So, ‘Why is Black Sublimation Turning Green? Probe the Possibilities!’ and unlock the secrets to mastering this fascinating craft.

The Chemistry Behind Sublimation

Sublimation is a fascinating process where a substance transitions directly from a solid to a gas without passing through the liquid state. In the world of printing and design, sublimation refers specifically to the transfer of dye onto a material.

Let’s sink into the chemistry that transforms these dyes during the sublimation process, sometimes leading to unexpected color changes like black turning green.

The Sublimation Process

The magic begins with heat and pressure. Upon heating, the solid dye converts into gas, which then penetrates the material’s fibers.

When it cools, the gas solidifies, leaving a vibrant, durable color that’s locked into the material.

- Heat: Triggers the solid to gas transition.

- Pressure: Ensures the gas enters the material’s surface.

- Cooling: Gas reverts to a solid state, coloring the material.

Factors Affecting Dye Behavior

Multiple factors can influence how dyes behave during sublimation, potentially leading to color shifts.

- Dye quality: Higher-grade dyes ensure truer colors.

- Substrate: The type of material receiving the dye impacts the final hue.

- Temperature and time: Precise control yields consistent results.

Chemical reactions between the dyes and diverse substrates under heat can cause unexpected outcomes. This is why meticulous calibration of the heat press machine is critical.

Common Causes For Color Distortion

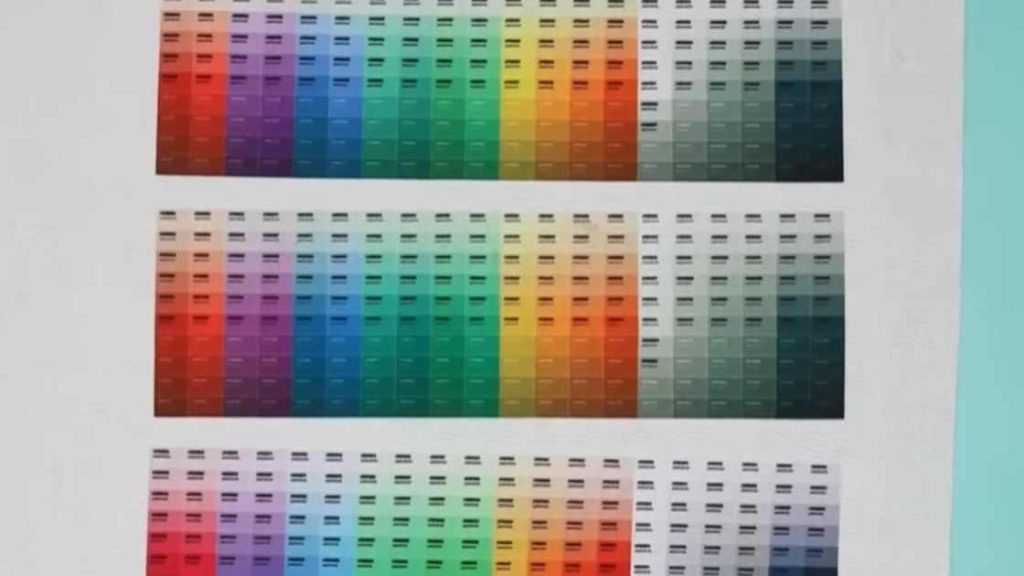

Sublimation printing is popular for creating vibrant designs. But sometimes, black turns green. Let’s examine why.

Material Composition

The type of fabric you use matters. Sublimation works best on polyester. Mixing it with other materials can cause color shifts.

- Pure polyester: Ideal for sublimation, and holds colors well.

- Poly-cotton blends: Colors can look faded or distorted.

- Non-polyester fabrics: Not suitable, cause unexpected color changes.

Heat Transfer Variables

Heat press settings are essential for color fidelity. Incorrect temperature and time lead to discoloration.

| Variable | Effect on Sublimation |

|---|---|

| Temperature | Too high or low affects ink transfer |

| Time | Insufficient or excess time alters colors |

| Pressure | Uneven pressure can cause green hues in blacks |

Consistent, even heat ensures accurate colors. Always check your heat press for uniform temperature distribution and correct timing for sharp, true-to-life colors on your finished product.

Black Dye Composition And Challenges

The black sublimation dye’s behavior is key for quality prints. Yet, this process sometimes deviates from expectations.

Why might black sublimation turn green? A closer look at black dye’s properties reveals the answer.

Properties Of Black Sublimation Dye

Black is not a simple color in sublimation printing. It’s a mix of different dyes. The composition of black sublimation dye is complex.

It often includes cyan, magenta, and yellow to achieve its deep tone. Each of these sub-dyes reacts under heat.

- Cyan: Adds depth to the black.

- Magenta: Provides a rich base.

- Yellow: Balances the darkness.

Heat sensitive, these sub-dyes create perfect black under ideal conditions. The dye turns black as it binds to the material. But color shifts can occur with any imbalance.

Challenges With Maintaining Color Integrity

Several factors can alter the true hue of black in sublimation printing, leading to colors like green creeping into the expected black.

| Challenge | Effect on Black Dye |

|---|---|

| Temperature Fluctuations | Can change dye binding and cause color shifts. |

| Pressure Inconsistency | May affect dye dispersal and final color. |

| Time Variation | Uneven exposure alters sub-dye activation. |

| Substrate Material | Different fabrics absorb dyes uniquely, impacting color. |

Each challenge affects how black dye sublimates. If cyan sub-dye underperforms, green tones might emerge.

To maintain color integrity, control, and consistency are essential. One must monitor temperature, pressure, time, and material choice closely.

Green Hue Formation Explained

Have you ever printed a perfect black design, only to find it has a greenish tinge? This common issue puzzles many sublimation enthusiasts.

Why black sublimation turns green requires diving into the science behind the sublimation process. Let’s Investigate what may cause those unexpected green hues.

Chemical Reactions Leading To Green Tint

Sublimation ink has a complex composition. During the heat transfer process, these inks undergo chemical changes. If not balanced, the black ink may cast a green shadow. Let’s break down the factors behind this phenomenon:

- Substrate Material: Some materials interact with inks differently.

- Ink Quality: Low-quality inks might not withstand high heat well.

- Heat Press Conditions: Temperature and time impact ink behavior.

Environmental Influences On Color Changes

External factors can also twist your black into green. Environmental variables affect sublimation results. These can range from air quality to storage conditions. Here’s what could be affecting your project:

| Factor | Effect on Sublimation |

|---|---|

| Humidity | Inks may absorb moisture, which alters color during transfer. |

| Temperature | Extreme cold or heat during storage can change ink properties. |

| Light Exposure | Ultraviolet light can degrade inks and alter colors over time. |

Troubleshooting Sublimation Issues

Facing issues with black sublimation prints turning green can be frustrating. It affects project outcomes. The core problems are essential. Let’s dip into troubleshooting techniques for better results.

Adjusting Heat Press Settings

Correct heat press settings ensure vibrant, accurate colors. Incorrect temperatures or times can alter the black dye, causing a greenish hue.

Here’s how to adjust:

- Check temperature: Verify the heat press reaches the recommended temperature for your sublimation ink.

- Consistent pressure: Uneven pressure leads to inconsistent color. Ensure your press applies uniform pressure across the substrate.

- Timing: Over or under-sublimation influences color quality. Match the timing specifically to your material and ink type.

After adjustments, test on a small sample. Compare the results.

Selecting The Right Substrate

Black turning green can signal a poor substrate choice. Only certain materials accept sublimation ink properly.

Follow these steps:

- Pick polyester-coated items: These accept the dye best. Sublimation requires at least a 60% polyester blend for optimal color.

- Avoid impurities: Ensure your substrate is clean. Residues affect dye adherence, causing color changes.

- Surface quality matters: A smooth surface allows for better ink contact and absorption. Rough or uneven surfaces can lead to color shifts.

Test different materials. Find which gives the truest black in your sublimation process.

Expert Tips For Ideal Black Sublimation

Achieving the perfect black in sublimation printing can be a challenge. Sometimes, black designs turn an unexpected shade of green.

Let’s sink into how to avoid this issue and keep your black sublimation prints true-to-color with some expert tips.

Preventing Greening In Future Projects

Color management is vital for ideal black sublimation. Use the right color profiles to match your printer, ink, and press. Ensure your graphics software settings are correct. Use high-quality ink and paper that are compatible with your substrate.

- Test Print: Always do a small test before full production.

- Temperature and Time: Use accurate heat press settings.

- Pressure: Even pressure prevents color shifts in sublimation.

| Aspect | Tip |

|---|---|

| Color Profiles | Match software and printer. |

| Ink and Paper | Choose high-quality. |

| Heat Press Settings | Ensure accuracy. |

| Pressure | Apply evenly. |

Maintenance Of Sublimation Equipment

Good equipment maintenance helps prevent green hues in black prints. Regularly clean and service your printer. Use clean nozzles and check for any clogs or issues with your printing machine.

Update printer drivers and firmware for the best performance. Keep your heat press clean and in good working order.

- Clean Regularly: Avoid ink build-up.

- Regular Checks: Monitor for clogs and damage.

- Update Software: Keep drivers up-to-date.

- Heat Press Care: Clean the plate often.

Case Studies: Overcoming The Green Hue Problem

Exploring Case Studies: Overcoming the Green Hue Problem sheds light on why black sublimation sometimes turns green. Faced by many in the sublimation community, this issue compromises the quality of products.

Here are real-world success stories and lessons revealing how to maintain the truest blacks in sublimation printing.

Success Stories From The Sublimation Community

The sublimation community is active and vibrant. Members often share their victories. These stories have become invaluable for beginners encountering the green hue dilemma.

- Case Study 1: Jenny’s Custom Tees managed to solve the green tint on their shirts. They adjusted their heat press temperature and time. Jenny’s now enjoys consistent black prints.

- Case Study 2: Mark’s Mugs found that using a different sublimation paper brand eliminated the issue. His mugs are now pitch-black, just as desired.

- Case Study 3: Bella’s Banners switched to a higher-quality sublimation ink. The green hue faded away, and their banners are now a deep, rich black.

Lessons Learned And Best Practices

From these stories, a pattern of best practices emerges. These practices are essential for tackling the green tint issue effectively.

- Temperature Control: Keeping the heat press at the right temperature prevents color shifts.

- Paper and Ink Quality: Invest in quality inks and papers designed for sublimation.

- Printer Maintenance: Regular cleanings ensure optimal printer performance and color accuracy.

- Community Engagement: Sharing experiences helps identify solutions faster.

Adopting these best practices leads to better sublimation results. Overcoming the green hue is possible with the right knowledge and tools.

Frequently Asked Questions For Why Is Black Sublimation Turning Green?

Why Is My Black Sublimation Turning Green?

Your black sublimation may turn green due to incorrect temperature settings, low-quality ink or substrate, or color profile issues. Adjusting these elements can help maintain true black tones.

Why Is My Black Sublimation Not Dark?

Your black sublimation may not be dark due to insufficient heat, low-quality ink or paper, incorrect pressing time, or a flawed transfer process. Ensure optimal temperatures, high-quality materials, and accurate timings for improved results.

Why Does Sublimation Change Color?

Sublimation changes color due to the dye’s chemical reaction with the substrate upon heating, resulting in vibrant, permanent colors.

Why Is My Black Sublimation Ink Not Transferring?

Your black sublimation ink might not transfer due to incorrect temperature settings, insufficient pressing time, a faulty printer, or low-quality ink or paper. Ensure all sublimation parameters are properly set and materials are compatible for successful transfer.

Can you sublimate color on black?

The request to sublimate the color to black involves a transformation process, turning the original color into a deep and rich black hue. This alteration can be achieved through different methods, such as sublimation printing or digital color adjustments.

Why is my black sublimation ink not transferring?

Your black sublimation ink may not be transferred due to insufficient heat or pressure during the sublimation process. Ensure that your heat press settings are accurate and that you are using compatible sublimation paper and substrates for optimal results.

Conclusion

Understanding the unusual shift from black to green in sublimation printing is essential for quality results. It’s often linked to incorrect settings or subpar materials. To ensure the true hues you desire, pay close attention to your equipment and ink choices.

Remember, successful sublimation is in the details. Keep experimenting, and you’ll master the perfect print.