Yes, you can sublimate on powder-coated tumblers with the right equipment and heat settings. The coating must be compatible with sublimation ink for a successful transfer.

Sublimation on powder-coated tumblers has become a popular way to create personalized and durable designs. This process requires a special type of ink that turns into gas when heated, transferring the design onto the tumbler’s surface.

The powder coating not only provides a perfect canvas for sublimation but also improves the durability of the print.

Crafters and DIY enthusiasts often use this method to produce high-quality, customized drinkware with vibrant, long-lasting graphics.

To make cool designs on cups, use the right cup, special ink, hot press, and control temperature.

Let’s see “How Can You Sublimate on Powder Coated Tumblers?”

The Basics Of Powder Coating And Sublimation

Tackling the art of tumblers often involves two dynamic processes: powder coating and sublimation. Both boast unique merits.

Their combination can lead to stunning and durable custom drinkware. Exploring these processes reveals their compatibility and potential for creativity.

Defining Powder Coating

Powder coating is a finishing technique. Dry powder covers objects. The process uses an electrostatic charge to stick powder to surfaces.

After application, objects enter a curing oven. This melts the powder into a smooth layer.

Sublimation Process: How It Works

Sublimation is a printing method. It turns solid ink into gas without becoming liquid. The gas binds with coated materials. Heat and pressure are crucial.

Designs transferred via sublimation are vivid and long-lasting.

Can sublimation combine with powder coating? Yes! For vibrant custom tumblers, ensure the coating can withstand high sublimation temperatures.

Compatibility Of Powder Coating With Sublimation

Ever wondered about customizing your powder-coated tumblers with vibrant images? Understanding the compatibility of powder coating with sublimation is key to achieving that eye-catching result.

Material Requirements For Sublimation

Sublimation is a magical process that requires specific materials:

- Polymer or polyester-coated tumblers to lock in the design.

- Sublimation ink and paper that transform into a gas when heated.

- A heat press that supplies the necessary temperature and pressure.

Impact Of Powder Coating On Sublimation

Can a tumbler’s powder coating befriend the sublimation process? Let’s find out:

| Type of Coating | Sublimation Compatibility |

|---|---|

| Standard Powder Coating: |

Often not suitable for sublimation due to its layering being too thick. |

| Specialized Sublimation Coating: |

Specifically designed to work with sublimation inks. |

Quality of finish and adhesion are both impacted when sublimating on powder-coated tumblers.

A smooth finish improves image clarity, while proper adhesion ensures durability.

Preparing Powder Coated Tumblers For Sublimation

Sublimating designs onto powder-coated tumblers offers a durable and vibrant finish. The process begins with suitable preparation.

This ensures the design adheres well and lasts. Below are essential steps to ready your tumblers for sublimation.

Surface Cleaning Techniques

Start by thoroughly cleaning the tumbler’s surface. Any dust, oil, or residue can hinder adhesion. Follow these steps:

- Wipe with Isopropyl Alcohol: Gently rub the tumbler with a clean cloth soaked in isopropyl alcohol. It removes oil and grime effectively.

- Dry Completely: Ensure the tumbler is bone dry before proceeding. Any moisture can affect the sublimation process.

- Lint-Free Cloth: Use a lint-free cloth for the final wipe to eliminate the chances of any fibers sticking to the surface.

Adhesion Promotion Strategies

To improve the adhesion of the sublimation ink, apply these strategies:

| Strategy | Benefits |

|---|---|

| Use a Sublimation Primer | Creates a chemically receptive layer for better ink absorption. |

| Heat Pre-treatment | Warms the tumbler to help the sublimation ink gasify evenly. |

| Tape Down Sublimation Paper | Prevents paper from moving during the process, ensuring sharp images. |

With these steps, you’re ready to sublimate designs onto your powder-coated tumblers with confidence.

Step-by-step Guide To Sublimating On Powder-Coated Tumblers

A Step-by-Step Guide to Sublimating on Powder Coated Tumblers ignites the possibility of creating vibrant, personalized drinkware. The process blends the durability of powder coating with the limitless creativity of sublimation printing.

Mastering this technique can transform simple tumblers into customized treasures. Follow this guide for flawless results.

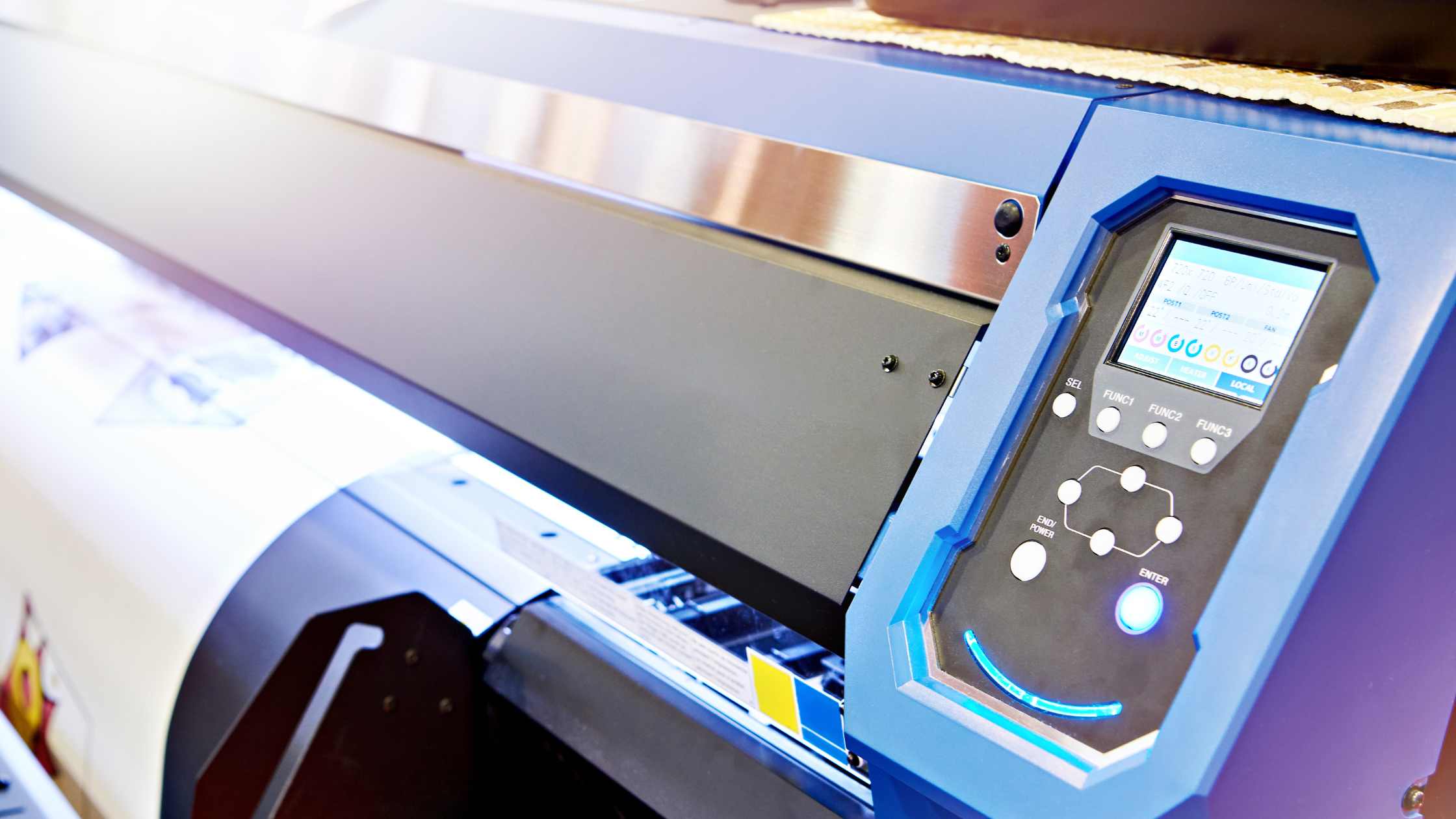

Choosing The Right Equipment

Selecting equipment is essential for sublimation success. Begin with a sublimation printer equipped with sublimation ink. Next, use heat-resistant tape and a quality tumbler press.

Ensure the tumbler selected is suitable for sublimation. It should have a polymer coating designed to withstand high temperatures and transfer images.

- Sublimation Printer: Essential for transferring your design.

- Sublimation Ink: Specifically formulated for the process.

- Heat-Resistant Tape: Secures the transfer paper in place.

- Tumbler Press: Applies even heat and pressure.

Temperature And Pressure Settings

The correct settings are vital to ensure a flawless transfer. Set your tumbler press between 360 to 400 degrees Fahrenheit. The pressure should be medium to firm.

Time settings may vary, but typically, 60 to 120 seconds suffice. Always check manufacturer recommendations for optimal results.

| Equipment | Temperature | Pressure | Time |

|---|---|---|---|

| Tumbler Press | 360-400°F | Medium to Firm | 60-120 Seconds |

Creative Ideas For Sublimated Tumbler Designs

Sublimation on powder-coated tumblers opens a world of creativity. Bright, bold designs stick to the surface, transforming plain tumblers into works of art.

These tumblers not only keep drinks at the perfect temperature but also reflect personal style. Ready to inspire your next project? Let’s explore some creative sublimation ideas!

Inspirational Patterns And Themes

Patterns and themes can set the tone for your tumbler. Visualize classic stripes, chevrons, or polka dots for a timeless look. Love nature? Wrap your tumbler with lush floral prints or wild animal patterns.

Seasonal themes offer a fun twist—think pumpkins for fall or snowflakes for winter. Choose patterns that reflect personality or season and turn the tumbler into a year-round accessory.

- Geometric Shapes – Circles, squares, or complex tessellations

- Nautical Stripes – Perfect for summer vibes

- Galaxy Prints – For a touch of the cosmos

- Festive Motifs – Holly jolly designs for the holidays

Personalization And Custom Graphics

Personalized tumblers make special gifts and promotional items. Add a name, a special date, or a favorite quote to make the tumbler one-of-a-kind. Consider line art, silhouettes, or even caricatures for a custom touch that stands out.

Businesses can print their logo and tagline on Tumblers for brand recognition. Whatever the choice, custom graphics ensure no two tumblers are alike.

- Monograms – Stylish initials for a personal touch

- Commemorative Dates – Mark an occasion with a special date

- Inspirational Quotes – Positive affirmations to lift the spirits

- Business Branding – Sleek designs for corporate swag

Troubleshooting Common Issues

Troubleshooting common issues with sublimation on powder-coated tumblers can be tricky. Perfect results demand attention to detail. Let’s solve some typical problems together!

Color Inconsistencies Explained

Vibrant, accurate colors are the goal of sublimation. Uneven heat or incorrect time settings often cause color issues. Here are common fixes:

- Check your sublimation printer settings. Use manufacturer-recommended settings.

- Calibrate your heat press for even temperature distribution.

- Test time and pressure with small adjustments.

Remember, every tumbler can behave differently. Always test before producing in bulk.

Addressing Adhesion Failures

When designs peel or fade, it’s often due to adhesion issues. Strong adhesion means vibrant, long-lasting designs. Follow these steps for better results:

- Clean the tumbler surface. Remove oils or residue before sublimating.

- Ensure your sublimation paper is fresh and high-quality.

- Adjust pressure. Too much or too little can affect adhesion.

Every detail matters in achieving the perfect sublimated tumbler.

Preserving The Longevity Of Your Sublimated Tumblers

Preserving the longevity of your sublimated tumblers ensures that the vibrant designs remain as eye-catching as the day they were crafted. With the right care, these personalized vessels can maintain their professional quality and appearance for years to come.

Whether you use these tumblers for your morning coffee or as a desk accessory, keeping them in pristine condition showcases their unique designs and your attention to detail.

Aftercare Best Practices

- Hand wash with mild soap and warm water.

- Avoid abrasive cleaners or tools that can scratch the surface.

- Dry immediately with a soft cloth to prevent water spots.

- Do not soak in water for long periods.

- Keep out of direct sunlight when not in use.

- Use a protective sleeve

Avoiding Common Wear And Tear

Despite their durability, powder-coated tumblers can lose their luster if exposed to harsh conditions. To prevent this:

| Action | Benefit |

|---|---|

| Store properly | Prevents dents and scratches |

| Avoid dishwashers | Maintains coating integrity |

| Limit sun exposure | Protects against fading |

Frequently Asked Questions Of Can You Sublimate On Powder Coated Tumblers

Can You Sublimate On Powder Coated?

Yes, you can sublimate on powder-coated materials, provided the coating is sublimation-friendly and exposes the material to the correct temperature and pressure for transferring the design effectively.

What Kind Of Tumblers Can You Sublimate On?

You can sublimate on poly-coated stainless steel and ceramic tumblers designed for sublimation. Ensure they have a sublimation-ready surface for ink adherence.

What Coating Is Needed For Sublimation?

For sublimation, a polyester coating or a poly-coat is essential. This special layer ensures the dye binds properly during the heat transfer process.

Can You Powder Coat Tumblers?

Yes, you can powder coat tumblers for a durable, customized finish. Ensure the tumbler is metal and prepped correctly before coating.

Does powder coating hold in heat?

Yes, powder coating is known for its excellent heat resistance, making it a durable and effective option for surfaces exposed to high temperatures.

It forms a resilient finish that can withstand heat without compromising its integrity.

Is powder coating heatproof?

Yes, powder coating is known for its heat-resistant properties, providing a durable finish that can withstand high temperatures.

It creates a strong shield that can handle heat, perfect for places that get really hot.

Conclusion

Exploring the possibilities of sublimation on powder-coated tumblers unlocks creative avenues. This technique improves custom products with vibrant, lasting prints. For hobbyists and entrepreneurs alike, it’s an exciting skill to master. Armed with the right knowledge, your personalized Tumbler projects are set to impress.

Let the sublimation journey begin, and watch your designs come to life!