To make laser printer toner powder, mix electrostatic induction material with organic solvent and ceramic inorganic pigment. The electrostatic induction material will be coated on the ceramic inorganic pigment.

Laser printer toner powder is made of various ingredients, including a specific polymer like styrene acrylate copolymer or polyester resin. Toner formulations differ among manufacturers and machines. The solvent used for laser printer toner is acetone, which helps release the toner from the paper.

To create toner ink powder at home, mix polyester with pigment and additives like fumed silica. This process helps produce individual toners for printing.

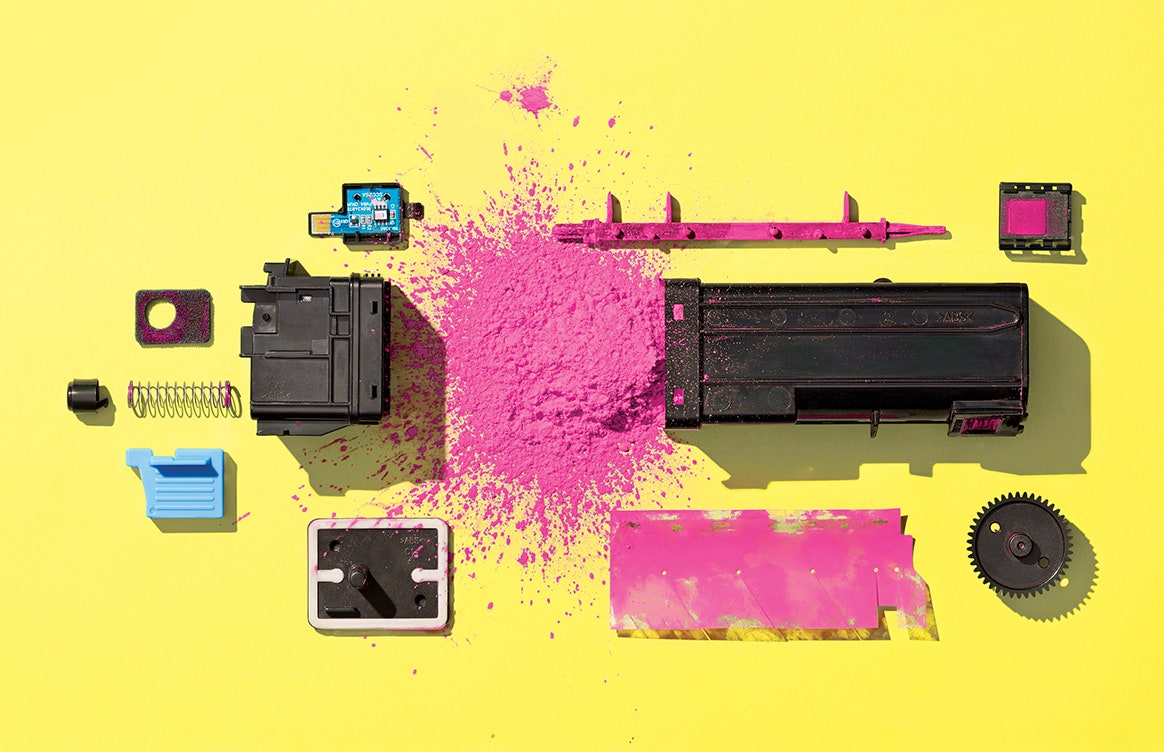

Introduction To Laser Printer Toner Powder

Laser printer toner powder is a crucial component in the printing process, essential for producing high-quality, long-lasting prints. Understanding the composition and evolution of toner technology is key to appreciating its significance in the printing industry.

Essential Components Of Toner

Modern laser printer toner powder is a composite material consisting of various components, including pigment, polymer, and other additives. The pigment provides color, while the polymer acts as the binding agent. Additionally, additives such as charge control agents and release agents contribute to the overall quality of the toner powder.

Evolution Of Toner Technology

The development of toner technology has undergone significant advancements over the years. Early toner formulations primarily used carbon powder, whereas modern toner incorporates advanced polymers and specialized additives to enhance print quality and longevity. This evolution has led to improved print resolution, faster printing speeds, and environmentally friendly toner formulations.

Credit: www.wikihow.com

Safety Considerations

To ensure safety when making laser printer toner powder, wear protective gear like gloves and a mask. Work in a well-ventilated area and handle the toner powder carefully to avoid inhaling or spilling it.

Handling Chemicals With Care

When handling chemicals, ensure proper ventilation in the workspace.

Label all containers with the correct contents to avoid mix-ups.

Store chemicals securely away from heat sources and direct sunlight.

Protective Gear Recommendations

Wear protective gloves to avoid skin contact with chemicals.

Safety goggles are essential to protect your eyes from potential splashes.

A lab coat or apron should be worn to protect clothing from spills and stains.

Toner Base Materials

Making laser printer toner powder involves a careful selection of toner base materials. These materials play a crucial role in determining the quality and performance of the toner. The toner base materials include polymer types and ceramic inorganic pigments, each of which contributes unique characteristics to the final toner powder.

Polymer Types

Polymers are a key component of toner base materials. They are responsible for creating the binding properties of the toner powder. Different polymer types are used in toner production, such as styrene acrylate copolymer, polyester resin, and styrene butadiene copolymer. Each polymer type offers specific attributes that influence the adhesion, durability, and print quality of the toner powder.

Role Of Ceramic Inorganic Pigments

Ceramic inorganic pigments play a crucial role in determining the color and vibrancy of the toner powder. These pigments are coated with electrostatic induction material to enhance their properties. Through careful selection and combination of ceramic inorganic pigments, the toner’s color accuracy and longevity can be optimized, ensuring high-quality print results.

Creating The Toner Mixture

To create the toner mixture for laser printer toner powder, combine electrostatic induction material with an organic solvent to form a static induction solution. Next, mix this with ceramic inorganic pigment to coat the material on the pigment effectively. This method results in the creation of polymerized toner for laser printers.

To make toner powder for a laser printer, you need to create a toner mixture. This is done by combining polymer and pigment in the right proportions and achieving the correct particle size. Here’s how you can create the toner mixture.

Combining Polymer And Pigment

The first step is to select the right polymer and pigment for the toner mixture. The polymer acts as a binder that holds the pigment particles together, while the pigment provides the color. The specific polymer and pigment used may vary depending on the manufacturer and the type of printer. Once you have selected the polymer and pigment, you need to mix them together in the right proportions. The exact proportions will depend on the desired color and other factors.

Achieving The Correct Particle Size

The next step is to achieve the correct particle size. The particle size is important because it determines how well the toner will adhere to the paper and how sharp the printed image will be. The particle size is typically controlled by grinding the toner particles to a specific size using a ball mill or other grinding equipment. The particle size is usually measured in microns, with smaller particles producing sharper images. To ensure that the toner mixture is consistent and uniform, it is important to mix the polymer and pigment thoroughly and to grind the toner particles to the desired size. Once the toner mixture is complete, it can be used to produce toner cartridges for laser printers. Overall, creating the toner mixture is a critical step in the production of toner powder for laser printers. By selecting the right polymer and pigment, and achieving the correct particle size, you can produce high-quality toner that produces sharp, clear images and adheres well to paper.

Electrostatic Properties

To create laser printer toner powder, mix electrostatic induction material with organic solvent to form a static induction solution. Combine this solution with ceramic inorganic pigment, coating the material on the pigment. This process results in the manufacturing of powder toner for laser printers.

Electrostatic Properties When it comes to making laser printer toner powder, understanding the electrostatic properties is essential. This is because toner powder relies on electrostatic charges to adhere to the printer’s drum and transfer onto paper. In this article, we will focus on the charge qualities and static induction solutions that are important for creating toner powder. Understanding Charge Qualities The charge qualities of toner powder are crucial for its functionality. The toner particles need to have a stable charge to ensure they stick to the printer’s drum and paper. The particles should be positively charged, and the printer’s drum should be negatively charged to achieve the desired effect. It is essential to maintain this balance to avoid issues such as poor print quality and clogging of the printer. Static Induction Solutions Static induction solutions are used to ensure that the toner particles have a stable charge. These solutions are made by mixing electrostatic induction materials with organic solvents. The resulting mixture is then combined with ceramic inorganic pigment, which coats the electrostatic induction material onto the pigment. This process creates a stable charge that is essential for the toner powder’s functionality. In conclusion, understanding the electrostatic properties of toner powder is crucial for making high-quality laser printer toner powder. Charge qualities and static induction solutions are key factors in creating toner powder that produces clear, sharp prints. By following these guidelines, you can ensure that your toner powder is of the highest quality and meets the needs of your printer.

Credit: m.youtube.com

Homemade Toner Vs. Commercial Toner

When considering the choice between homemade toner and commercial toner, it’s essential to weigh the advantages and limitations of each option. Homemade toner offers a cost-effective and customizable alternative to commercial toner. On the other hand, commercial toner is manufactured with precise formulations to ensure optimal performance and quality. Understanding the differences between these two options is crucial for making an informed decision.

Diy Toner Challenges

Creating toner powder at home presents several challenges that can impact its quality and performance. One of the primary challenges is sourcing high-quality raw materials, such as polymer resins and pigments, which may not be readily available to consumers. Additionally, achieving the precise particle size distribution and chemical composition found in commercial toner is difficult without specialized equipment and expertise.

Quality And Performance Comparison

When comparing homemade toner to commercial toner, the quality and performance are key considerations. Commercial toner undergoes rigorous testing and manufacturing processes to ensure consistent particle size, shape, and distribution, resulting in superior print quality and longevity. Homemade toner may lack the same level of precision, potentially leading to issues such as uneven distribution, toner clumping, and subpar print results.

Transforming Toner Powder To Liquid Ink

Solvents For Toner Release

Acetone is a common solvent for toner release, causing the toner to detach from the paper surface.

Other solvents like ethyl acetate and methyl ethyl ketone are also used for toner separation.

Liquid Toner Applications

Liquid toners are utilized in digital printing for high-quality image reproduction.

These toners offer vibrant colors and sharp details on various printing substrates.

Practical Applications And Experiments

Making laser printer toner powder at home opens up a world of practical applications and exciting experiments. From creating unique art projects to exploring alternative uses for toner powder, the possibilities are endless. Let’s delve into some fascinating practical applications and experiments with homemade toner powder.

Toner For Ceramics Transfer

One interesting practical application of homemade toner powder is transferring images onto ceramics. By utilizing the heat transfer method, you can print an image using a laser printer and then transfer it onto a ceramic surface. The toner acts as a transfer medium, allowing the image to adhere to the ceramic material. This technique offers endless opportunities for creating custom-designed ceramics and personalized gifts.

Alternative Uses For Toner Powder

Aside from its traditional use in laser printing, toner powder has a range of alternative applications. It can be used in experimental art projects, such as creating textured paintings or mixed media artworks. Additionally, toner powder can be employed in educational experiments to demonstrate principles of static electricity and magnetic attraction. The versatile nature of toner powder makes it a valuable resource for creative experimentation and exploration.

Environmental And Economic Aspects

When it comes to laser printer toner powder, there are important environmental and economic aspects to consider. Recycling and reusing toner cartridges can significantly reduce waste and environmental impact. Additionally, making your own toner powder can be a cost-effective and sustainable alternative to purchasing new cartridges. Let’s delve into the environmental and economic benefits of these practices.

Recycling And Reusing Toner Cartridges

Recycling and reusing toner cartridges play a crucial role in reducing electronic waste. By refilling and reusing cartridges, we can minimize the number of cartridges that end up in landfills, thus lowering the environmental impact of printing. Moreover, remanufacturing toner cartridges requires less energy and raw materials compared to producing new ones, making it an environmentally friendly option.

Cost-benefit Analysis Of Diy Toner

Engaging in DIY toner production can yield significant cost savings. By sourcing raw materials and producing toner powder at home, individuals and businesses can cut down on expenses associated with purchasing new cartridges. This approach not only offers economic benefits but also reduces the environmental footprint by promoting sustainability and reducing waste.

Credit: www.wired.com

Conclusion And Safety Recap

To wrap up, making laser printer toner powder at home requires caution and attention to safety. It’s important to handle the materials carefully, wear protective gear, and work in a well-ventilated area to avoid inhaling the fine powder. Safety should always be the top priority when working with toner powder.

Summarizing The Diy Process

Making laser printer toner powder involves mixing electrostatic induction material with organic solvent and ceramic inorganic pigment. The polymer used in toner powder varies by manufacturer and can be a styrene acrylate copolymer, polyester resin, or styrene butadiene copolymer. Toner formulations differ among manufacturers and machines, resulting in varying compositions.

Final Safety Reminders

- Handle toner powder in a well-ventilated area to avoid inhaling particles.

- Wear gloves and a mask to protect skin and respiratory system.

- Avoid contact with eyes and wash hands thoroughly after handling toner.

- Store toner powder in a sealed container away from heat and moisture.

Remember to follow safety precautions and guidelines when making laser printer toner powder at home. By understanding the DIY process and prioritizing safety measures, you can create toner powder effectively while minimizing potential risks.

Frequently Asked Questions

How To Make Laser Toner Powder?

To make laser toner powder, mix electrostatic induction material with organic solvent to form a solution. Then mix the solution with ceramic inorganic pigment to coat the material on the pigment. The specific polymer used can vary, such as styrene acrylate copolymer or polyester resin.

What Is Laser Printer Toner Powder Made Of?

Laser printer toner powder is made of a mixture of polymer, ceramic inorganic pigment, and electrostatic induction material.

What Are The Ingredients In Toner Powder?

Toner powder ingredients include polymer, pigment, and solvent, varying among manufacturers and machines.

What Solvent To Use For Laser Printer Toner?

The recommended solvent to use for laser printer toner is acetone. When applied to the back of the paper, acetone will release the toner, allowing it to bond to a new surface below. It is important to note that toner formulations vary by manufacturer and machine.

Polyester is often mixed with each pigment to produce individual toners, along with fumed silica or microscopic glass beads.

How Is Laser Printer Toner Powder Made?

Laser printer toner powder is made by mixing the electrostatic induction material with organic solvent to form a static induction solution. This solution is then mixed with ceramic inorganic pigment to coat the electrostatic induction material onto the pigment.

Conclusion

Creating laser printer toner powder involves a meticulous process of mixing electrostatic induction material with organic solvents. Understanding the composition and manufacturing methods is essential for producing high-quality toner. By following proper techniques, you can make your own toner effectively at home.