Yes, you can sublimate on both sides of a shirt, but it requires a careful process. Ensure the fabric is suitable for sublimation and that you protect the previously printed side.

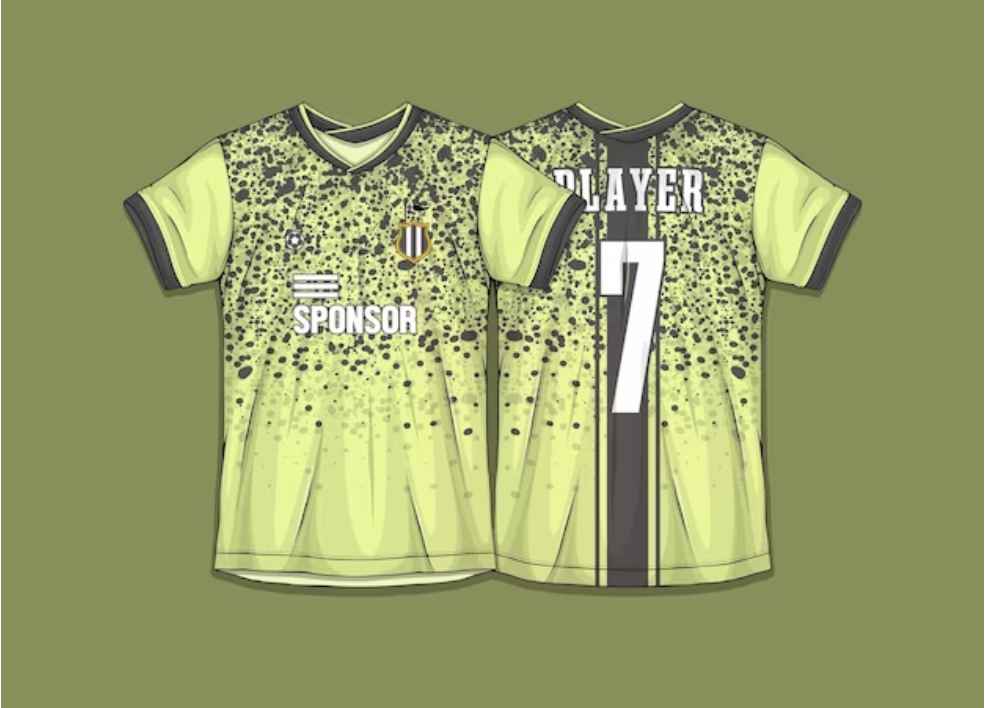

Sublimating both sides of a shirt opens a realm of creativity for designers and custom apparel enthusiasts.

This technique involves using heat to transfer dye onto materials, mostly polyester or poly-coated substrates.

Care must be taken to prevent the dye from bleeding through or distorting the initial side’s design.

Precision is key, as is the choice of fabric; a 100% polyester garment ensures vivid colors and durability of print.

Sublimation printing is celebrated for its high-quality results, making it a popular method for creating custom tees that stand out in both personal and commercial markets.

With the right equipment, a heat press that applies consistent pressure and temperature, and a design that resonates, transforming an ordinary shirt into a double-sided masterpiece is entirely achievable.

Exploring Sublimation On Shirts: Basics And Possibilities

Sublimation printing has revolutionized the world of custom apparel.

With its vibrant colors and crisp images, it has opened up new possibilities for personalized shirts. In the blog post section below, we explore the basics of sublimating shirts and discuss whether doing it on both sides is a possibility.

The Science Behind Sublimation Printing

Sublimation is a process where a solid turns into a gas without becoming liquid. This science works wonders in printing. For shirts, a special dye turns into a gas under heat and pressure.

It then bonds with the shirt’s fabric. As it cools, it turns back into a solid. The result is a permanent, high-quality print that doesn’t fade or crack.

Materials Fit For Sublimation

- Polyester – Ideal for sublimation, allowing vibrant and lasting prints.

- Poly-coated items – Sublimation requires a polymer surface to adhere properly.

- Mixed fabrics – Poly-cotton blends can also work, but the print may look vintage as cotton doesn’t take the dye as well.

To sublimate on both sides of a shirt, both sides must be made of suitable material. The item is printed one side at a time to ensure quality.

Heat-resistant foam or pads protect the already printed side during the second side’s sublimation.

The Two-sided Question: Can It Be Done?

Printable shirts are a canvas for creativity. Doubts often arise on whether sublimation can occur on both sides of a shirt. Is this process viable for a double-sided fashion statement? Let’s explore.

Sublimation On Both Sides: Myth Or Reality?

Sublimation on both shirt sides is real. This technique allows vibrant designs on the front and back. The trickiness lies in proper execution.

- Heat press accuracy is necessary for aligning designs.

- The use of specialized sublimation paper ensures quality.

- Correct temperature control avoids ghosting effects.

Technical Limitations And How To Overcome Them

Technical challenges may intimidate, but solutions exist. Awareness and preparation are crucial for success.

| Limitation | Solution |

|---|---|

| Ink Bleeding | Use blowout paper between layers |

| Heat Press Marks | Employ Teflon pillows to even out the pressure |

| Design Misalignment | Laser-guided placement helps with precision |

Mastering two-sided sublimation calls for practice and patience. Embrace these solutions and bring your double-sided designs to life with confidence.

Apparel Selection For Dual-sided Sublimation

Sublimating both sides of a shirt opens doors to creativity, but selecting the perfect apparel is key. The right choice ensures vibrant prints on each side. Let us dive into the specifics of choosing the best apparel for double-sided prints.

Identifying The Right Fabrics For Double-side Prints

Not all fabrics are fit for sublimation printing. Polyesters work best as they absorb the ink, making the design last. Natural fibers like cotton may not hold the dye on both sides as well. A minimum of 65% polyester is recommended for optimal results. Here’s a quick guide:

- High Polyester Content: Preferred for vibrant, lasting prints.

- Blended Fabrics: Lesser color brilliance but still viable.

- Coated Cotton: Possible but not ideal, as the coat may wear off.

The Thickness Factor In Dual-sided Sublimation

The thickness of the fabric is crucial. Thin materials may cause bleed-through. This can ruin the design on the opposite side. Medium to heavyweight fabrics prevent this problem. Consider these options:

| Fabric Type | Thickness | Suitability |

|---|---|---|

| Lightweight Polyester | Thin | Least suitable |

| Polyester-Cotton Blend | Medium | Moderately suitable |

| Polyester Canvas | Thick | Most suitable |

Aim for fabric with a good balance of weight and fiber content. This results in clear, sharp images on both sides of the shirt with no interference.

Mastering The Sublimation Process: Double-Sided Technique

Unlock the full potential of fabric customization with double-sided sublimation. Print vibrant designs on both sides of a shirt with precision. Discover tips and tricks for a flawless transfer that turns heads from every direction.

Step-by-step Guide For Sublimating Both Sides

Follow these steps to master double-sided sublimation:

- Choose the right fabric. Poly-rich blends work best.

- Print mirror images of your design for both sides.

- Prep your press. Ensure even temperature across the plate.

- Press one side. Use protective paper to avoid bleed-through.

- Let it cool. Prevent ghosting by waiting before the flip.

- Align the second side. Precision is key for a clean look.

- Repeat the process. Press with care.

- Cool again. Allow the shirt to settle and the ink to cure.

Avoiding Common Mistakes With Dual Printing

Avoid errors in your double-sided sublimation:

- Prevent ghosting: Let each side cool down fully.

- Stop bleed-through: Insert protective paper inside the shirt.

- Ensure alignment: Use guides for precise positioning.

- Avoid pressure marks: Adjust your heat press pressure.

- Test your settings: Do a trial run to nail the process.

Finesse is essential in double-sided sublimation. Every move counts towards a stunning, seamless finish on your apparel. Join the ranks of sublimation experts with these foolproof techniques for dual-sided printing.

Critical Tools And Equipment For Successful Sublimation

Sublimation printing offers endless creativity, and double-sided shirts are no exception. Yet, to reach the pinnacle of sublimation excellence, the right tools and equipment are vital. Whether a professional or a hobbyist, understanding the tools needed for successful two-sided sublimation enhances the quality and efficiency of your projects.

Must-have Sublimation Tools For Double-sided Printing

Double-sided sublimation requires more than just enthusiasm. One must equip their arsenal with specifically designed tools. Here’s a concise list:

- Sublimation Printer: A high-quality sublimation printer ensures vibrant colors on both sides.

- Sublimation Ink: Specialized sublimation ink that bonds with the fabric for long-lasting prints.

- Heat Press: A reliable heat press with an even temperature distribution is crucial for pressing both sides.

- Sublimation Paper: This transfer paper holds the ink and releases it under heat onto the fabric.

- Heat-Resistant Tape: Keeps the paper in place during pressing, preventing ghosting.

- Protective Paper: Prevents ink bleed-through and protects the press.

Upgrading Your Equipment For Dual-sided Projects

Advancing from single to double-sided printing involves upgrading your toolset. A swing-away heat press allows for easy shirt maneuvering. Consider specialized platens designed to prevent press marks on the opposite side.

Use laser temperature guns to ensure precise heat settings. Finally, a high-caliber printer elevates the crispness and vivacity of your designs.

Invest in tools that enhance your workflow:

| Tool | Function | Impact |

|---|---|---|

| Swing-Away Heat Press | Uniform pressure application | Improves quality |

| Specialized Platens | Reduces press marks | Ensures smooth prints |

| Laser Temperature Gun | Monitors heat accuracy | Prevents overheating |

| Premium Sublimation Printer | Produces high-resolution prints | Boosts design clarity |

Design Considerations For Sublimating On Both Sides

Creating double-sided sublimated shirts offers unique value. It enables custom, vivid designs that stand out. However, it poses specific design challenges to ensure high-quality results. When printing on both sides of a shirt, careful planning is crucial. Key aspects include coordinating designs and managing potential color issues.

Crafting Complementary Front And Back Designs

Double-sided sublimation requires seamless designs that tell a story. Designs need balance. The front should connect to the back visually and thematically. A table of complementary themes can help with the selection process:

| Front Design Theme | Back Design Theme |

|---|---|

| Daytime Cityscape | Night Skyline |

| Floral Front | Monochrome Patterned Back |

| Cartoon Character Face | Character Motto |

Align elements at the edges to ensure cohesion. The transition between the front and back should be fluid.

Managing Color Overlap And Bleed Through

During sublimation, ink can spread. Colors might bleed through the thin fabric. Choosing high-quality, opaque materials minimizes this.

- Perform a bleed test on the fabric.

- Adjust color saturation accordingly.

- Use thicker fabric to prevent bleed-through.

Plan designs with overlapping elements on the sides. This avoids unsightly gaps. Ensure ink levels are correct. Too much ink and the colors might bleed. Too little, and the design may appear faded.

Tips, Tricks, And Best Practices From Industry Professionals

Unlocking the full potential of your shirts with sublimation printing just got intriguing. Industry professionals share insider tips, tricks, and best practices for mastering double-sided sublimation. Let’s dive into the expert advice to elevate your craft.

Expert Advice For Double-sided Sublimation

- Pre-test your fabric to ensure quality and color fastness.

- Maintain consistent pressure and heat across both sides.

- Use protective paper to prevent ink from bleeding through.

- Implement a cool-down period after pressing each side.

- Adjust artwork placement considering the shirt’s seams and folds.

Remember, precision is key. For vibrant and lasting results, use high-quality inks and papers. Experts recommend testing different products to find what works best for your designs.

Creative Ideas And Inspirations For Your Designs

Double-sided sublimation opens a world of creative possibilities. From matching front and back themes to interactive designs that play across the shirt, the canvas is yours to craft.

| Front Design Concept | Back Design Concept |

|---|---|

| Daytime cityscape | Night-time cityscape with glow effects |

| Portrait with a quote | Continuation of the portrait or full biography |

| Floral pattern starting on the front | Floral pattern blooming across the back |

Envision your designs coming together for a seamless storytelling experience. With careful planning and a touch of creativity, every shirt becomes a wearable piece of art.

Frequently Asked Questions Of Can You Sublimate On Both Sides Of A Shirt

Can You Sublimate Both Sides At Once?

No, you cannot sublimate both sides of a material simultaneously. Sublimation printing requires one side to be printed at a time.

Can You Heat Press Both Sides Of A Shirt?

Yes, you can heat-press both sides of a shirt. Just ensure each side is pressed separately and use a protective sheet to avoid heat damage.

Can You Print On Either Side Of Sublimation Paper?

Sublimation paper is specific; you must print on the coated side designed to accept the ink. Printing on the uncoated side results in poor image transfer quality. Always check which side is correct before printing for optimal results.

Can You Overlap Sublimation?

Yes, you can overlap designs during sublimation, but ensure colors and patterns align properly to avoid unwanted blending or ghosting effects. Use heat-resistant tape for precision.

Conclusion

Sublimating on both sides of a shirt is indeed possible. With proper technique and equipment, vibrant, lasting designs come to life. Embrace creativity and experiment with double-sided sublimation to make your shirts stand out. Remember to follow guidelines for quality results.

Happy printing!