Sublimate on Fabric Modal is challenging due to its heat sensitivity. Modal requires a special sublimation process to avoid damage.

Sublimation printing has become a popular method for transferring vivid and intricate designs onto various types of fabrics.

Modal fabric, known for its softness and high absorbency, presents a unique set of challenges for this process.

The delicate nature of modal fibers demands a gentle approach to the high heat typically used for sublimation.

Enthusiasts and professionals in the garment printing industry must navigate these challenges to achieve clear, long-lasting prints on modal garments.

By understanding the specific needs of the modal, you can enhance the efficacy of sublimation printing on this increasingly popular fabric, ensuring quality results without compromising the integrity of the material.

The Basics Of Sublimation On Modal Fabric

The Basics of Sublimation on Modal Fabric heralds a new era for do-it-yourself fashion enthusiasts and small business owners alike.

Sublimation offers the allure of vibrant prints infused into the fabric, rather than merely lying on top.

When it comes to Modal fabric, a popular choice for its softness and breathability, understanding the process is critical to achieving enduring and striking designs.

Understanding Sublimation Printing

Sublimation printing is like magic for fabrics. It turns solid dye into gas with heat, bonding it with the material. This results in prints that do not peel or fade over time.

Colors stay bright, and images remain sharp, wash after wash.

In simple steps, create a design, print it onto special paper, and then transfer it with heat onto your chosen fabric.

Properties Of Modal Fabric

Modal fabric shines in the textile world for good reasons. Made from beech tree fibers, it is eco-friendly and luxuriously soft.

Its breathability is perfect for sportswear and intimate apparel. Fortified with high strength and moisture-wicking properties, Modal is ideal for daily wear.

Sublimate on Modal, and you get comfort with personalized style.

Note: Success in sublimating Modal fabric heavily relies on fabric composition.

Pure Modal may not yield the best results due to its cellulose base. Blends with synthetic fibers, such as polyester, improve sublimation outcomes.

| Factor | Consideration |

|---|---|

| Fabric Content | Look for Modal blends with at least 50% polyester for vivid colors. |

| Heat Press | Ensure even heat distribution for an impeccable transfer. |

| Timing | Adhere to recommended press times to prevent burning or underdeveloped colors. |

When preparing to sublimate on Modal blends, pre-testing is crucial. Sample prints help to adjust settings for the perfect finish.

Always use a protective layer like parchment paper to guard against dye bleeding. Respect the fabric’s delicate nature by selecting a low temperature and shorter press time compared to polyester.

Compatibility Of Modal With Sublimation

Exploring the art of sublimation on different fabrics opens up a treasure trove of possibilities. One such fabric is modal, popular for its softness and shine.

Let’s delve into how modal fabric teams up with the sublimation process.

Fiber Content And Dye Reception

Modal is a type of rayon, a semi-synthetic fabric made from beech tree pulp. In the sublimation world, fiber content plays a pivotal role.

Fabrics with high polyester content are typically best for sublimation, as they hold the ink well and present vibrant outcomes.

Although modal is not polyester, it can still partake in the sublimation process—albeit with nuanced considerations.

- Blend Ratios Matter: A modal blend with a significant percentage of polyester can improve dye reception.

- Temperature and Pressure: Modal might require specific conditions, such as lower heat and gentle pressure, to avoid damage.

- Dye Uptake: While not optimal, modal can absorb dyes but may result in more muted tones.

Challenges With Natural Fibers

Natural fibers, like modal, present specific challenges. These fibers don’t have the dye-locking attributes that synthetic fibers possess.

Sublimation ink turns into gas and seeks out polymers to bond with, which are not present in natural fibers.

- Polymer Coating Solution: Applying a pre-treatment polymer coat on a modal can aid in mimicking the dye-reception properties of synthetics.

- Fabric Conditioning: Pre-conditioning the fabric might be necessary to enhance the print quality and washability.

- Outcome Expectation: Be ready for results that may not be as vivid as seen on polyester. Modal can create a vintage or subtly stylish look.

Sublimation on modal requires patience and experimentation. Each step, from pre-treatment to heat pressing, demands attention.

Yet with care, the process can yield unique and custom designs on a fabric known for comfort.

Preparing Modal Fabric For Sublimation

Sublimation printing offers vibrant and lasting results on fabrics. Preparing Modal Fabric for Sublimation is a key step to ensure quality prints.

Let’s uncover how to get Modal fabric ready for a stunning sublimation design.

Pre-treatment Methods

To start, clean the Modal fabric to remove impurities. A pre-treatment solution may then be applied. This solution helps sublimation ink bond better with the fabric. The fabric should be evenly coated and dried. Follow these steps:

- Launder the fabric to eliminate dust and oils.

- Prepare a sublimation pre-treatment mix. This mix typically includes a pre-treatment liquid and distilled water.

- Apply the mixture using a spray bottle or a dipping method.

- Ensure the fabric is completely dry before sublimating. You can use a heat press for quick drying.

Importance Of Fabric Purity

The purity of Modal fabric matters for sublimation printing. Impurities can cause ink to spread unevenly or not adhere well, leading to dull prints. Always:

- Check the fabric for stains or marks before printing.

- Use high-quality pre-treatment solutions designed for sublimation.

- Test print on a small area to ensure the fabric responds well.

Step-by-step Guide To Sublimating On Modal

Modal fabric, known for its soft texture and high durability, is a fantastic medium for vibrant prints. Sublimation printing on Modal requires precision to maintain its quality. This step-by-step guide simplifies the process, ensuring brilliant results every time.

Choosing The Right Sublimation Paper

The key to vivid prints on Modal lies in selecting the proper sublimation paper.

- Opt for a high-quality paper that ensures maximum ink transfer.

- Ensure compatibility with your printer for smooth operations.

Temperature And Time Settings

Modal responds well to heat, but optimal temperature and time are crucial for sublimation.

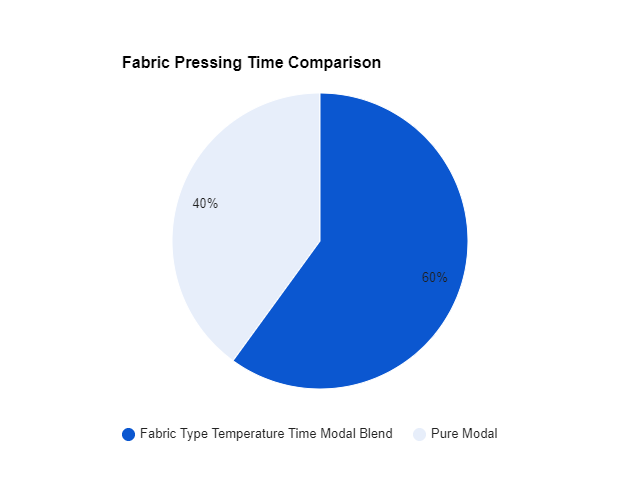

| Fabric Type | Temperature | Time |

|---|---|---|

| Modal Blend | 375° F (190° C) | 45 seconds |

| Pure Modal | 400° F (204° C) | 30 seconds |

Preheat your press to the required temperature. Press for the exact time to prevent overexposure.

Troubleshooting Common Issues

You are encountering challenges while sublimating on modal fabrics? Whether you’re new to sublimation printing or have encountered bumps, this comprehensive guide illuminates common issues and delivers solutions to keep your designs vibrant and long-lasting.

Avoiding Sublimation Mistakes

Prepping is key for optimal sublimation on modal — a semi-synthetic fabric known for its softness and smoothness. However, its delicate nature can trip you up if you’re not careful. Here’s how to avoid common missteps:

- Check your fabric composition: Pure modal doesn’t sublimate well. Aim for a blend with a high polyester content.

- Keep your press clean: Residue from previous prints can transfer unwanted color.

- Use proper heat settings: Modal can scorch easily. Test different temperatures for the best outcome.

- Ensure even pressure: Inconsistencies in pressure result in uneven transfers. Routinely inspect your press.

Fixes For Sublimation Fading

Struggling with designs that fade too quickly?

Let’s tackle the fade factor: Modal fibers can be tricky, often leading to designs that don’t quite hold up over time.

| Issue | Cause | Solution |

|---|---|---|

| Fading after washing | Aggressive laundering | Wash inside out with cold water; low tumble dry or air dry |

| Image clarity loss | Low polyester content | Choose a modal blend with at least 50% polyester |

| Color not vivid | Inadequate heat | Increase press temperature but watch for scorching |

| Quick color degradation | UV exposure | Limit direct sunlight exposure on the fabric |

Ensuring the Longevity Of Sublimated Modal Fabrics

Modal fabric merges comfort with longevity. Sublimating on modal requires care. Proper techniques extend life. This guide covers key care steps for longevity.

Post-sublimation Care Tips

After sublimation, proper care is crucial. Follow these tips:

- Avoid Heat: Keep fabric away from direct heat.

- Shade Dry: Dry your fabric in shade.

- Soft Ironing: Iron at low temperatures if needed.

Effective Washing Techniques

To wash sublimated modal fabrics, follow these steps:

- Cold Water: Use cold water for washing.

- Mild Detergent: Gentle Pick detergents.

- Inside Out: Turn clothes inside out before washing.

Hand Wash: For best results, hand wash gently.

| Step | Method |

|---|---|

| 1 | Fill basin with cold water |

| 2 | Add mild detergent |

| 3 | Submerge and swish gently |

| 4 | Rinse with clean water |

| 5 | Press out water, don’t wring |

Follow these tips for longevity.

Creative Projects With Sublimated Modal

Creative projects shine when you mix art and fabric technology. Enter the world of sublimating modal fabric—an exciting fusion begging for creative minds. This how-to guide will help unleash your imagination. Bring your designs to life on this luxurious textile.

Fashion And Apparel Innovations

Breathe new life into wardrobes with custom sublimated pieces on modal fabric. Soft, stretchy, and vibrant, modal makes a perfect canvas for fashion. Here’s what you can create:

- T-shirts that showcase brilliant, lasting colors

- Scarves with detailed patterns that pop

- Leggings that stay bright, wash after wash

Designers can push boundaries thanks to modal’s high-quality print receptivity. This leads to stunning, long-lasting apparel items.

Home Decor Applications

Transform living spaces with sublimated modal accents. This unique material adds a touch of elegance to any room, and sublimation ensures your designs remain fade-resistant and beautiful. Consider these home decor ideas:

| Modal Home Decor Item | Design Ideas |

|---|---|

| Cushion Covers | Botanical prints, abstract art |

| Throw Blankets | Geometric patterns, personalized messages |

| Wall Hangings | Landscape scenes, inspirational quotes |

Sublimated modal offers a sleek, sophisticated touch, turning the ordinary into extraordinary.

Frequently Asked Questions For Sublimate on Fabric Modal? (the How To Guide)

Can I Heat Press Modal Fabric?

Yes, you can heat press modal fabric but use a lower temperature and a press cloth to prevent scorching. Always conduct a test press first.

What Fabrics Are Compatible With Sublimation?

Sublimation printing works best on polyester and polymer-coated fabrics. High polyester content yields the most vibrant colors. Natural fibers like cotton do not hold sublimation ink well, resulting in faded prints. Blends can work but with less vivid results compared to 100% polyester.

What Material Is Modal Made Of?

Modal fabric is made from the cellulose of beech trees, and processed into a soft and durable fiber.

Can You Sublimate On 50% Polyester 25% Cotton, and 25% Rayon?

Yes, you can sublimate on a 50% polyester, 25% cotton, 25% rayon blend. However, the resulting image may be less vibrant due to the lower polyester content. For optimal results, aim for higher polyester percentages.

Is sublimation only for polyester?

No, sublimation is not exclusive to polyester. While polyester is commonly used in sublimation printing due to its receptive properties, sublimation can also be applied to other materials like ceramics, metals, and certain coated surfaces for vibrant and durable prints.

Can you sublimate on muslin?

Yes, sublimation can be applied to muslin fabric, allowing for vibrant and durable printed designs on this versatile material.

Can I sublimate on 100% cotton?

Yes, sublimation works best on polyester fabrics, as it requires a high synthetic content to adhere effectively; therefore, sublimating on 100% cotton may not yield optimal results.

Can you sublimate on rayon?

Yes, sublimation is generally possible on rayon fabric, as it is a synthetic material that can withstand the sublimation process. However, it is advisable to check the specific characteristics of the rayon fabric to ensure compatibility with sublimation techniques.

Conclusion

Exploring the art of sublimation on modal fabric opens creative doors. By following proper techniques, you can achieve vibrant, lasting prints.

Remember, temperature control and testing are crucial. Embrace the process and enjoy personalizing your modal creations with unique designs.

Happy printing!