A cutter may not respond to the poll size due to a communication error or incorrect settings. To solve this issue, check connections and configure settings properly.

When tackling the issue of a non-responsive cutter concerning the poll size, users often experience frustration. Troubleshooting this problem involves a systematic approach to identifying and resolving the root cause.

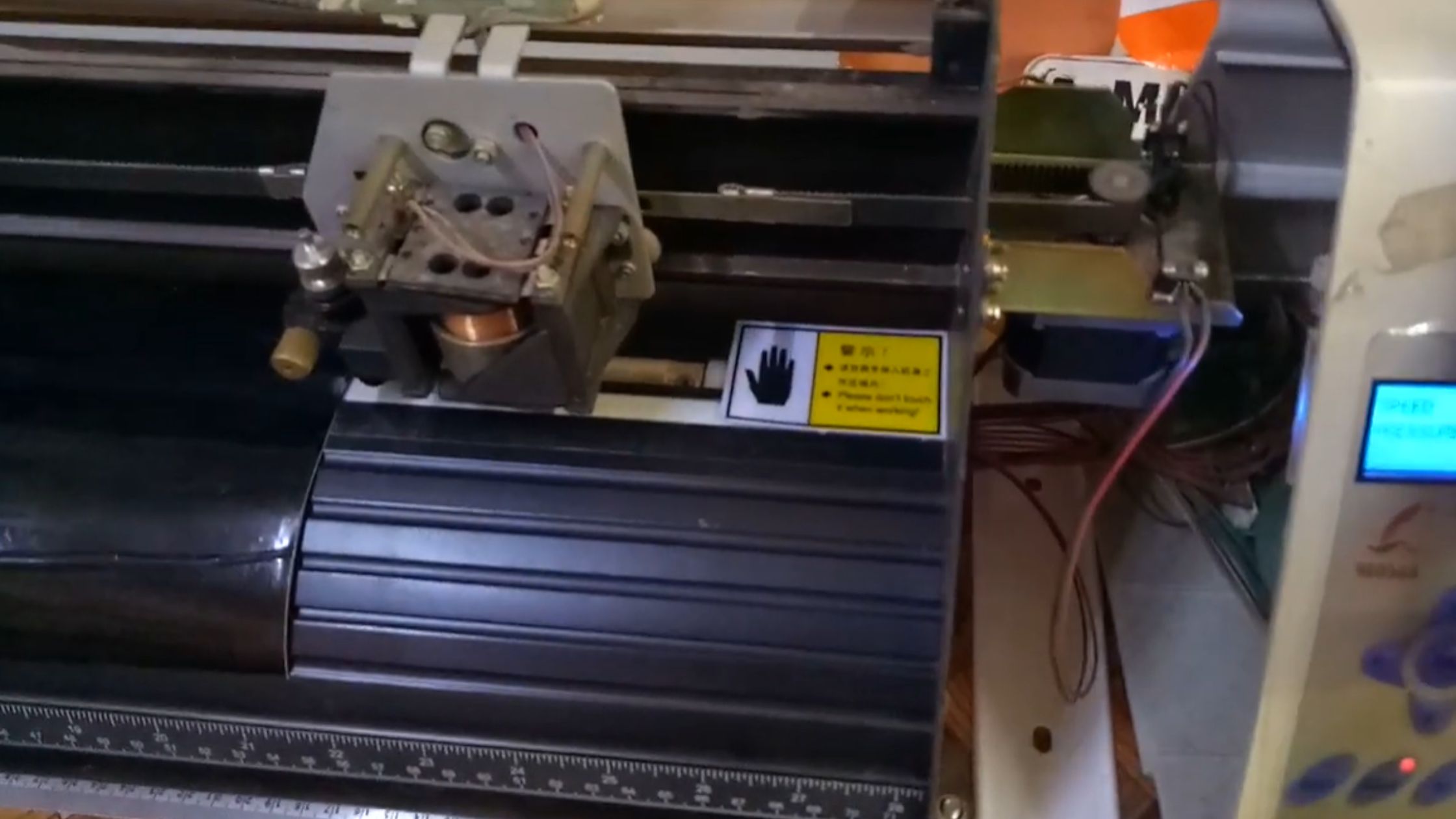

A cutter, which is an integral part of various industries, such as manufacturing or design, relies on accurate settings to function correctly.

In the realm of managing digital cutters, whether they’re tailored for vinyl or paper, or robust industrial cutters handling heavier materials, the pivotal concern revolves around the responsiveness of your equipment to control inputs. Now, delving into the intricacies of the matter, one may ponder, “Why Is Cutter Not Responding to Poll Size?”

This question becomes a linchpin, shedding light on the core issue at hand. As we explore the nuances, it becomes evident that ensuring seamless operation is not just a preference but a necessity, aligning with the demands for efficiency and precision in operations utilizing such machinery.

Let’s unravel the common causes and unveil the straightforward solutions, striving to reinstate the cutter’s responsiveness and uphold the standards of operational excellence.

The Essence Of Poll Size In Cutter Performance

Poll size directly impacts the efficiency of a cutter. It determines how well the cutter will engage with the material. An appropriate poll size means smooth and precise cuts. A mismatch can lead to several performance issues.

The Critical Role Of Poll Size

Cutters work best when the poll size matches the material thickness. This balance ensures optimal cutting speed and minimum wear. For instance, a saw blade needs the right poll size to cut wood effectively. Precise poll size translates to better control and cleaner cuts.

- Enhanced accuracy: Correct poll size improves cutting precision.

- Reduced strain: Matches tool to task, minimizing tool stress.

Consequences Of Ignoring Poll Size

Overlooking poll size can have negative outcomes. Improper poll size can cause tool failures.

| Damaged Tools | Poor Quality Cuts | Safety Hazards |

|---|---|---|

| Blunt or broken edges | Inconsistent finishing | Increased risk of accidents |

Addressing the issue involves reviewing the manufacturer’s specifications. Matching the poll size with the task ensures the cutter responds correctly. A simple adjustment might be all it takes to enhance cutter performance.

Diagnosing Non-responsiveness In Cutters

Diagnosing Non-Responsiveness in Cutters can be challenging. Many professionals face this issue when their cutter ignores the set poll size. Narrowing down the causes requires a systematic approach. Below, we dive into the troubleshooting steps for cutters that are not responding as they should.

Identifying Symptoms

Recognizing the primary signs that point to non-responsiveness is the first step.

- The cutter moves randomly: It does not follow the expected path.

- Incorrect output: The size of the cut materials is wrong.

- Errors in software: Unexpected messages or alerts appear.

- Laggy performance: Slow reaction to commands.

Common Diagnostic Tools

Using the right tools will simplify the troubleshooting process.

- Software Diagnostics: Check for updates or bugs in the operating software.

- Mechanical Inspection: Examine the cutter for any physical obstructions or malfunctions.

- Connectivity Check: Ensure cables and connections are intact and functional.

- Log Analysis: Review the system logs for any anomalies.

To effectively solve the issue, professionals might need to combine multiple tools for a comprehensive diagnosis.

Factors Affecting Cutter Responsiveness To Poll Size

Finding out why a cutter isn’t reacting to poll size can be tricky. It’s like being a detective in a manufacturing mystery. Think of poll size as a puzzle piece. When that piece doesn’t fit, the cutter won’t work right.

To fix it, you need to know what affects the cutter’s responsiveness. Let’s dive into the factors that can cause such issues.

Material Attributes

Materials are like different flavors of ice cream – they all behave differently. Some are soft and easy to scoop, while others are hard and need more effort. The same goes for materials that the cutter processes.

- Hardness: Tough materials may need more power.

- Thickness: Thicker materials might slow the cutter down.

- Stickiness: Sticky materials can cause the cutter to jam.

The trick is to match the poll size to the material. When the fit is wrong, the cutter might stop responding. To solve it, adjust the settings to suit the material’s attributes.

Machine Wear And Tear

Like a well-loved teddy bear, machines can show signs of wear and tear. Over time, parts can wear out and affect how the cutter responds.

| Machine Part | Wear and Tear Sign | Impact on Responsiveness |

|---|---|---|

| Blades | Dullness | Slower, imprecise cuts |

| Motors | Less power | Struggles with harder materials |

| Sensors | Calibration issues | Poor response to controls |

To get the cutter back on track, replace or repair worn parts. Regular maintenance keeps the machine happy and productive.

Add any additional content if needed but remember to keep it simple, clean, and concise, focusing on keeping it easy to read for kids.Troubleshooting Guide For Unresponsive Cutters

Welcome to our ‘Troubleshooting Guide for Unresponsive Cutters’. Cutters not responding to the poll size can halt productivity. This guide delivers step-by-step solutions to get your cutter back in action.

Initial Checks And Balancing

Start with the basics. Ensure connections and settings are correct. Follow these steps:

- Check the cutter’s power supply.

- Verify the poll size settings in the software.

- Ensure USB or RS-232 cables are securely plugged in.

- Inspect the blade and holder for any damage.

If these steps don’t work, balance might be an issue. Adjust balance using:

- The cutter’s balance controls, if available.

- Manual calibration, following the manufacturer’s instructions.

Advanced Diagnostic Procedures

If initial checks fail, proceed with the advanced diagnostic procedures. Tackle more complex issues:

- Analyze error messages on the cutter or software.

- Run self-diagnostic tests, if your cutter has this feature.

- Consult the manual for specific troubleshooting codes.

Look for firmware updates. Updates can fix bugs or compatibility issues. Perform updates as follows:

1. Visit manufacturer's website.

2. Download the latest firmware.

3. Use the update function in your cutter’s software.

Optimizing Cutter Settings For Desired Poll Size

Optimizing Cutter Settings for Desired Poll Size is crucial for any precision-driven industry. From woodworking to metal fabrication, the right settings are vital for efficiency and product quality. Commonly, issues arise when cutters do not respond to poll size settings.

Users often overlook the calibration of their equipment and material variations. Properly adjusting these settings will ensure accurate and consistent results.

Calibration Techniques

Cutters require regular calibration to maintain precision. Here’s how to calibrate your cutter correctly:

- Check the manufacturer’s instructions. Each model has specific calibration steps.

- Use calibration tools. These might include gauges or software provided with the cutter.

- Run test cuts. After adjusting, perform tests to ensure accuracy.

Adjusting For Material Variations

Materials can affect poll size responses due to their thickness and density. Follow these steps:

| Material Type | Action | Outcome |

|---|---|---|

| Thick | Increase force or slow down the cut | Precise cut without strain |

| Dense | Adjust blade depth | Clean edges |

| Varied | Use multi-depth cutting | Uniform results |

Preventive Maintenance Strategies

Are you facing issues with your cutter not adjusting to poll size? You’re not alone. Many face this technical hiccup, often due to a lack of maintenance.

Let’s dive into how preventive maintenance strategies can keep cutters responsive and efficient.

Scheduled Cutter Care

Regularly scheduled maintenance extends cutter life and performance. Note these key steps:

- Inspect blades for wear and damage.

- Clean cutter components to remove debris.

- Lubricate moving parts to prevent friction.

- Check and tighten loose bolts and connections.

- Replace worn-out parts before they fail.

A sleek cutter always delivers top-notch results. Stick to a monthly or quarterly maintenance timetable. Your cutter’s manual includes specific intervals and procedures.

Predictive Maintenance Tools

Modern predictive tools spot potential issues before they arise. They include:

| Tool | Function |

|---|---|

| Vibration Analysis | Detects unusual vibrations signaling wear. |

| Thermal Imaging | Identifies heat patterns that suggest electrical issues. |

| Acoustic Monitoring | Picks up noise anomalies hinting at mechanical faults. |

Use these tools as part of your ongoing cutter oversight. They help plan maintenance work before unexpected downtime affects your operation.

Adapting To Technological Advances In Cutting Tools

In the world of manufacturing, precision and efficiency reign supreme. Operators rely on cutting tools to shape materials to exact specifications. Yet, sometimes these tools fail to respond to different poll sizes.

Why does this happen? It could be a lack of innovation or outdated technology. Adapting to new advances can solve it. Let’s delve into the innovations and emerging technologies that make cutters more versatile.

Innovations In Cutter Design

Design enhancements in cutting tools lead to performance boosts. Improved materials and geometries contribute to this. Let’s look at these innovations:

- High-Performance Alloys: Cutters made of novel alloys stand up to stringent tasks.

- Smart Geometries: Modern cutter designs lead to less wear and better performance.

- Coatings: Advanced coatings reduce friction and extend tool life.

Emerging Poll Size Adaptation Technologies

Tools that adapt to different poll sizes are key. Technology now delivers this flexibility. The following breakthroughs represent how:

- Auto-Adjust Mechanisms: Cutters automatically adjust the poll size in real-time.

- Programmable Controls: Users can input poll size data, and the tool configures accordingly.

- Sensors and Feedback Systems: Real-time monitoring and adjustments improve accuracy and adaptability.

With these advances, cutting tools become dynamic instruments. They cater to varied manufacturing demands. Problems with poll size responsiveness are in the past.

Case Studies: Recovering Cutter Responsiveness

Exploring how cutters regain their precision offers valuable insights for operators facing similar issues. The ‘Case Studies: Recovering Cutter Responsiveness’ section dives deep into real-world examples.

It uncovers proven strategies that bring cutters back in line. The focus revolves around success stories and expert advice that paved the way for effective problem-solving.

Success Stories

Cutters stalling in their response can halt production. Yet, some workshops rebound with remarkable agility. Their stories often start with common problems and end with innovative fixes.

We’ve noted cases where adjusting the poll size itself broke the deadlock, whereas, in others, a software update was the hero of the hour.

- Company A: Discovered issues in their calibration process.

- Company B: Identified outdated firmware causing delays.

- Company C: Simplified their data input method, resolving errors.

Lessons Learned From Field Experts

Experts in the field offer invaluable advice based on years of troubleshooting. Tapping into their wisdom showcases common themes in restoring cutter performance.

| Action Taken | Result |

|---|---|

| Software Updates | Improved response times and accuracy |

| Hardware Calibration | Enhanced cutter precision |

| Regular Maintenance | Consistent cutter performance |

Notably, one expert suggests maintaining a regular log of cutter activities to preempt future issues. This proactive approach has been a game-changer for many organizations.

Frequently Asked Questions Of Why Is Cutter Not Responding To Poll Size And How To Solve It

Why Isn’t My Cutter Recognizing The Poll Size?

The cutter may not be detecting the poll size due to outdated firmware or incorrect settings. Ensure your cutter’s software is up-to-date and confirm the poll size settings match the material being used.

How To Fix A Cutter Poll Size Detection Issue?

Start by checking the cutter’s manual for the correct poll size settings. If those are correct, recalibrate the sensor if possible. You might also try resetting the cutter or contacting the manufacturer for support.

Can Software Updates Affect Cutter Poll Size Response?

Yes, software updates can influence how the cutter responds to poll sizes. It’s crucial to keep the cutter’s software updated to maintain compatibility and performance, especially when it comes to handling specific tasks like poll size detection.

What To Do If Cutter Still Won’t Respond To Size Settings?

If your cutter is unresponsive to size settings, try a complete power cycle. If this doesn’t work, inspect the cutter’s mechanical components for any obstructions, and consider reaching out to technical support for further assistance.

Conclusion

Troubleshooting an unresponsive cutter involves checking poll size settings and examining the tool for damage. Simple solutions can restore function quickly. If problems persist, seeking professional advice is recommended. Remember, maintenance and regular updates prevent most issues. Your cutter should be back in action with these tips.