A heat press tripping a circuit breaker often indicates an electrical overload or a fault in the machine. Resolving this requires checking the press’s power requirements and breaker capacity.

In the dynamic realm of custom printing and design, a dependable heat press stands as a cornerstone, playing a vital role in achieving impeccable transfers across various materials. The vexing issue of circuit breakers repeatedly tripping poses a formidable challenge, disrupting the creative flow and potentially causing business interruptions.

Delving into the intricacies of a heat press and its electrical requirements becomes imperative for a seamless operational experience. The key lies in ensuring that your workspace boasts the proper electrical infrastructure, effectively preventing the common headache of breaker tripping. This hiccup often results from either overloaded circuits or an internal glitch within the heat press itself. Pinpointing and rectifying the root cause not only elevates safety standards but also optimizes the overall performance and lifespan of your trusty heat press.

So, why does your heat press keep tripping breaker? Unraveling this mystery is the first step towards a more efficient and uninterrupted custom printing journey.

Common Reasons For Circuit Breaker Trips

When a heat press trips a circuit breaker, two main issues often arise electrical overload and short circuits.

Electrical Overload And Heat Press Demands

High electricity demand can lead to an electrical overload. Think of this like trying to pour a gallon of water down a small funnel all at once – it’s too much, too quickly. The heat press requires a lot of energy, and if multiple devices are on the same circuit, your breaker may trip to prevent damage.

- Assess your circuit capacity: Compare the power requirements of your heat press and other appliances versus your circuit’s capacity.

- Check appliance usage: Is the heat press sharing a circuit with other high-power devices? This could cause a trip.

- Test with different outlets: Try using the heat press on a circuit with a heavier load capacity.

Short Circuit: A Potential Culprit

A short circuit happens when a wire carrying current touches another, creating a new path for electricity with less resistance. This unexpected path can cause a sudden surge of electricity, triggering your breaker. Like a sprinter taking a shortcut on the track, this can lead to a chaotic finish!

- Inspect for visible damage: Check your heat press’s power cord and plug for any signs of damage.

- Feel for warmth: If cords or plugs feel unusually warm, this could indicate a short circuit.

- Professional assessment: Consider hiring an electrician to inspect your device and electrical system.

Assessing Your Heat Press Power Requirements

Heat presses are a staple in the custom apparel industry, but power issues like a tripped breaker can halt production. This section helps identify the electrical needs of your heat press to prevent such issues.

Comprehension A heat press requires a specific amount of power to operate efficiently. Knowing the two key components – wattage and amperage is essential. Wattage measures the power consumption, and amperage, the current flow. To avoid tripped breakers, check your heat press’ power rating and ensure your outlet meets the demand.

Wattage (W) can be calculated using the formula: Watts = Volts x Amps. Use this formula to understand whether your current electrical setup can handle the heat press. If the calculated wattage exceeds your outlet’s capacity, a breaker trip is likely.

Amperage (A), on the other hand, can cause a breaker to trip if the heat press draws more current than what the circuit can handle. It’s vital to assess the amperage of your heat press and compare it with the breaker’s rating.

Manufacturer’s Specifications And Electrical Compliance

Always refer to the manufacturer’s specifications before plugging in your heat press. These specifications can be found in the user manual or on a sticker on the device. They provide valuable information about the required voltage, wattage, and amperage.

- Required voltage: Ensure your electrical outlet provides the correct voltage.

- Wattage and amperage: Match these specs with your breaker’s capacity.

Electrical compliance is also critical. Check local codes and standards to ensure your setup complies with safety regulations. A compliant setup will uphold safety and prevent damage to the equipment.

If you find discrepancies between your heat press’s requirements and your electrical system, it’s time to seek a qualified electrician’s assistance.

Evaluating Your Electrical Circuit

Does your heat press machine trip the breaker? The electrical circuit in your space is key. Let’s solve this now. The circuit must handle the heat press power without overloading. We’ll dip into why breakers trip and the solution.

Circuit Capacity Vs. Heat Press Consumption

Does your heat press demand more than the circuit can supply? This mismatch causes breakers to trip.

- Check the machine’s wattage. It’s on the spec sheet.

- Now, look at your breaker. It shows maximum amps.

- Watts divided by volts equals amps. This tells if your circuit can cope.

Is the heat press too powerful? You might need a circuit upgrade.

Aging Wiring And Its Risks

Old wires can be a hazard. They may not handle current demands safely. Let’s uncover this:

| Signs of Aging Wiring | What To Do |

|---|---|

| Discoloration around outlets | Inspect circuit |

| Burning smell from wires | Contact electrician |

| Frequent tripping | Consider rewiring |

Upgrade old wires to prevent fire risks and tripping. Professional assessment is vital.

Heat Press Settings And Usage Impact

Are you facing issues with your heat press tripping the breaker? Don’t worry! Often, the way we use our heat press machines can affect their electrical load. This impacts the circuit breaker. Different settings and usage patterns can either ease the burden or trigger a shutdown. Let’s explore these factors.

Temperature And Timer Settings

Setting the right temperature and timer on your heat-press is essential. Here are key points to remember:

- Check the material guide: Use the recommended temperature.

- Gradual increase: Avoid sudden spikes in temperature settings.

- Timer accuracy: Set the timer as per the printing needs.

Using a heat press outside the advised settings can overload the circuit. This may cause the breaker to trip. Always follow the manual for safe operation.

Continuous Operation And Its Effects

Continuous use of a heat press machine generates constant heat, putting pressure on the circuit. Continuous operation can lead to:

- Increased energy consumption.

- Heat build-up in the machine.

- Higher risk of the breaker tripping.

To avoid these issues, allow the machine to rest between sessions. This will help distribute energy usage. It also reduces the chance of overloading the circuit. Always monitor machine operation closely.

Troubleshooting Steps To Identify The Issue

When your heat press keeps tripping the breaker, don’t panic. We’ll walk you through some key steps to help find a solution. Follow these troubleshooting actions to get your heat press up and running smoothly again.

Visual Inspection For Damage Or Wear

Start with a thorough check of the heat press. Look for signs of damage like frayed cords or cracked casings. Worn equipment could be the culprit. Here’s what to keep an eye out for:

- Inspect the power cord for bends, tears, or burns.

- Examine the heat plate to ensure it’s not warped or cracked.

- Check all connections to make sure they’re tight and secure.

Any sign of wear necessitates immediate attention. Address these issues before your next use.

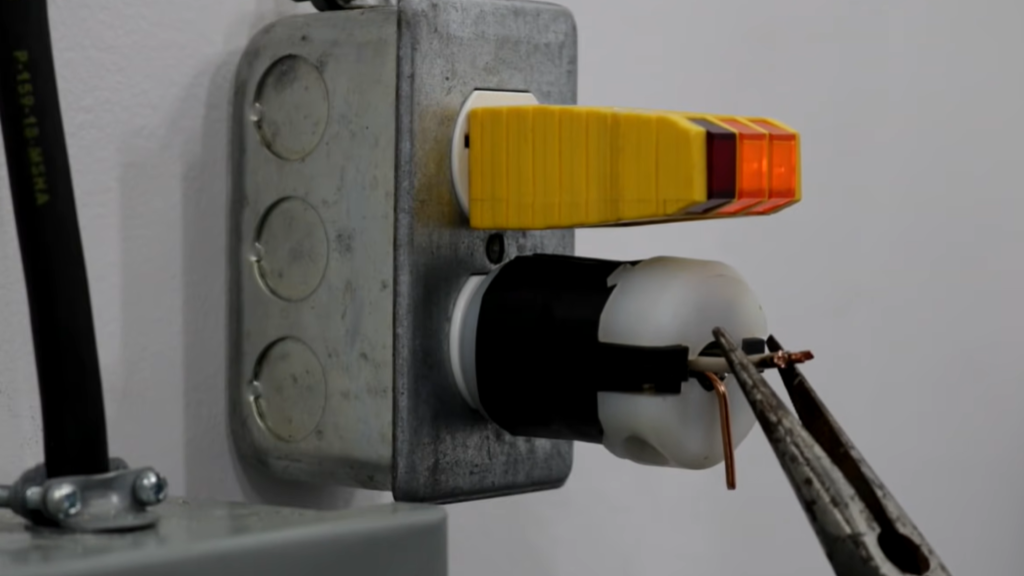

Testing The Outlet And Breaker Functionality

It’s essential to evaluate the electric supply. Your outlet and breaker may be at fault. Conduct a test to see if other devices trip the breaker. Here’s how:

- Plug another device into the same outlet and switch it on.

- Reset the breaker if it trips again.

- If the breaker keeps tripping, there may be an issue with the electrical circuit.

| Action | Expected Outcome | Possible Solution |

|---|---|---|

| Plug in a different device | The device works without tripping | The heat press may need repairs |

| Reset the breaker | Breaker stays on | Outlet is fine |

| Test another outlet | Heat press works | The original outlet might be faulty |

If other devices also cause a trip, the outlet or breaker needs a professional evaluation. Ensure the electrical workload is appropriate for your equipment setup.

Diy Fixes That Can Prevent Tripping

If your heat press keeps tripping your breaker, don’t panic. Simple DIY fixes can often solve the problem. Prevent unnecessary trips and ensure your heat press operates smoothly. Before you call a professional, try these methods to keep your breaker intact.

Resetting And Testing The Breaker

To reset a tripped breaker, follow these steps:

- Locate your electrical panel. This is usually found in a basement or garage.

- Identify the tripped breaker. It’s often in the “off” position or a middle position.

- Flip the breaker to the “off” position. Then, turn it to the “on” position.

- Test your heat press. Restart the machine to see if it trips the breaker again.

If the breaker trips again, there may be an overload. Reduce other electrical usage on the same circuit when using your heat press.

Upgrading The Power Outlet

Old or inadequate outlets can cause trips. Upgrading them can prevent this issue:

- Check the outlet’s rating. Ensure it’s suitable for your heat press’s power needs.

- Upgrade to a higher capacity outlet. If needed, choose one that can handle more amperage.

- Consider a dedicated circuit. This provides a separate electrical line for your heat press.

Always ensure a certified electrician performs any upgrades. They can ensure all upgrades meet the necessary safety standards.

When To Call The Professionals

Experiencing repeated breaker trips with your heat press can signal a need for professional insight. Seek an electrician’s expertise to safely resolve power issues and ensure your equipment functions optimally.

If your heat press keeps tripping your breaker, it’s essential to act fast. While some issues might be simple to fix on your own, others signal deeper electrical problems. Calling a professional electrician is the safest move. They can diagnose the problem accurately and repair it without risking further damage to your equipment or property.

Signs Of Complex Electrical Issues

Look out for these warning signs, as they often require a professional touch:

- Frequent breaker trips when using other appliances

- Burning smell from outlets or the heat press

- Visible damage to the wiring

- Unexplained power outages in your work area

Never ignore these signs—they can lead to dangerous situations like electrical fires.

Choosing The Right Electrician For Your Needs

Selecting a skilled electrician is key to fixing your heat press breaker issue effectively. Consider these steps:

- Look for licensed and insured professionals

- Check reviews and ratings online

- Request quotes and compare prices

- Ask about their experience with heat press machines

Remember, a reliable electrician will provide a thorough assessment and a clear explanation of the issue.

Preventative Measures For Future Stability

To maintain the smooth operation of your heat-press, certain preventive steps are essential. A heat press tripping a breaker is inconvenient. These strategies will keep the machine stable and secure, avoiding abrupt work stoppages.

Regular Maintenance Schedule

Just like any machine, a heat press requires regular check-ups. Set a maintenance schedule to prevent future issues. This routine should include:

- Inspecting wiring for damage or wear

- Cleaning electrical components

- Checking the heat platen for consistency

Noting any changes or potential problems early saves time and money.

Investment In Surge Protectors And Dedicated Circuits

Protecting your equipment is essential. Surge protectors prevent voltage spikes from harming your heat press. A dedicated circuit ensures the press doesn’t share power, which can cause trips.

| Protection Method | Benefits |

|---|---|

| Surge Protectors | Shields against electrical surges |

| Dedicated Circuit | Prevents breaker trips |

Investing in these protections can make a big difference in performance.

Best Practices For Heat Press Users

Ensuring a well-functioning heat press is essential. Let’s sink into the best practices. This ensures optimal performance and safety.

Summarizing Key Takeaways

- Check electrical requirements: Ensure the press matches your outlet’s voltage.

- Inspect your circuit breaker: It should handle the heat press’s amperage.

- Consider a dedicated circuit: This prevents tripping from overloaded circuits.

- Monitor press condition: Look for wear and tear routinely.

- Follow manufacturer guidelines: Adhere to the provided instructions for use.

Maintaining Safety And Efficiency

Maintaining your heat press is key to preventing issues.

| Action | Benefit |

|---|---|

| Regular inspections | Promotes longevity and safety. |

| Clear workspace | Reduces risk of accidents. |

| Proper handling | Ensures consistent results. |

Implement these steps, and enjoy uninterrupted heat pressing.

Frequently Asked Questions On Heat Press Keep Tripping Breaker

Why Does My Heat Press Keep Tripping The Breaker?

Your heat press may trip the breaker due to an electrical overload, a short circuit, a faulty machine, or an inadequate power supply. Check your device’s power requirements and ensure the circuit can handle it. If problems persist, consult a professional electrician or the manufacturer.

Why Does My Heat Keep Tripping The Breaker?

Your heat may trip the breaker due to electrical issues, overheating, circuit overload, or a faulty heater. It’s essential to diagnose and address the root cause promptly to ensure safety and proper functioning.

Why Does My Heat Press Keep Shutting Off?

Your heat press might be shutting off due to overheating, a faulty thermostat, electrical issues, or a malfunctioning timer. Check for proper ventilation, inspect electrical connections, and consider consulting a technician for repairs.

How Do You Fix A Breaker That Keeps Tripping?

To fix a breaker that keeps tripping, first, unplug all devices on the circuit. Reset the breaker by flipping it off, and then on. If it trips again without a load, contact an electrician to check for wiring issues or breaker faults.

Why Does My Heater Trip The Breaker After A Few Minutes?

Your heater may be overloading the circuit, causing the breaker to trip. Check for any electrical issues, such as faulty wiring or a malfunctioning heating element, and consider consulting a professional for proper diagnosis and repair.

Can A Heating Element Cause A Breaker To Trip?

Yes, a heating element can cause a breaker to trip if it draws more current than the circuit can handle, leading to an overload and triggering the circuit breaker’s protective mechanism. This is a safety feature designed to prevent overheating and potential fire hazards.

Conclusion

Troubleshooting a heat press that trips your breaker need not be a headache any longer. Our guide has provided clear steps to diagnose and solve common issues. Remember, safety is paramount when handling electrical equipment. By following the solutions outlined, your heat press should operate smoothly, ensuring your crafting continues without interruption.

Keep crafting with confidence!