A heat press blowing fuse typically involves electrical issues or a faulty heating element. Troubleshoot by checking the power supply, wiring, and elements.

Dealing with heat press machines is usually a smooth process, but encountering the recurring issue of blowing fuses can be quite perplexing.

If your heat press keeps blowing fuses, it’s a clear indicator of an underlying electrical glitch. This hiccup can be incredibly vexing, disrupting your workflow and impeding productivity.

To keep your heat press functioning optimally, it’s crucial to incorporate regular maintenance into your routine and develop a discerning eye for troubleshooting.

The key here is to meticulously address and resolve fuse-related problems, as they play a pivotal role in the machine’s overall durability and the quality of the final products.

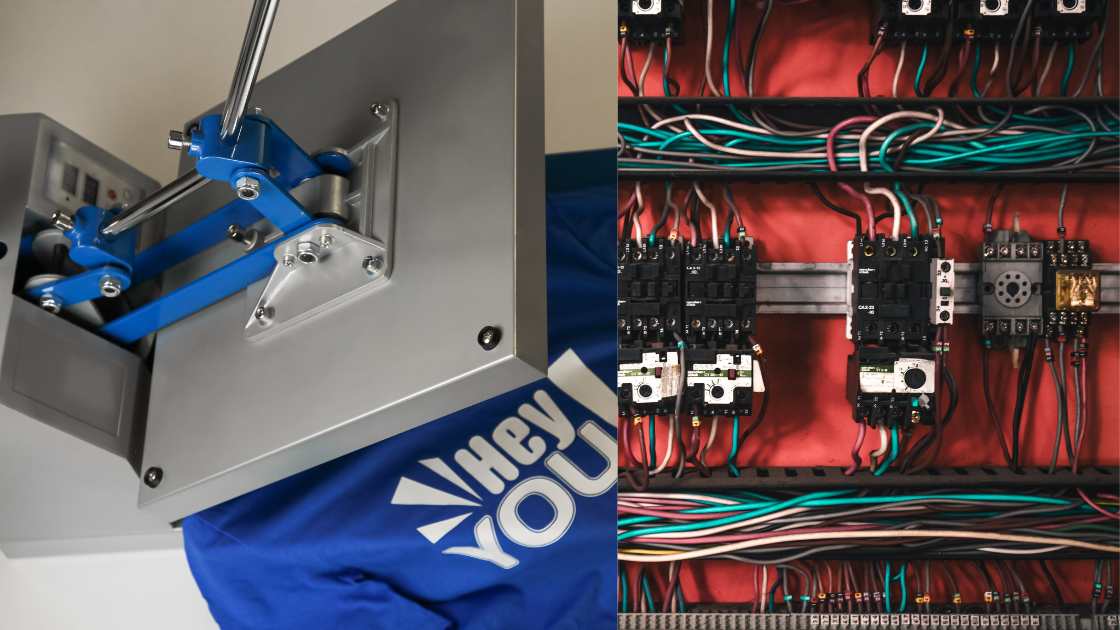

Take a methodical approach when facing such challenges. Carefully inspect every electrical component of the heat press, ensuring that everything, from the power supply to the heating element, is in perfect working order.

This proactive measure not only serves to prevent future fuse blowouts but also guarantees the safety and efficiency of your entire heat press operation.

Common Causes Of Fuse Issues In Heat Press Machines

Interpretation of why a heat press machine keeps blowing a fuse can be frustrating. Several factors play a role.

Pinpointing the issue is the first step to a lasting solution. Here, we investigate the most common causes that could lead to this infuriating problem.

Overloading The Electrical Circuit

An overloaded electrical circuit is a frequent culprit when fuses blow. Heat presses demand significant power. If other high-energy devices share the circuit, the system may exceed its capacity.

This results in a blown fuse. Ensure your heat press has a dedicated power source to avoid overloading.

Short Circuit Within The Press

A short circuit occurs when electrical flow veers off the intended path, often due to exposed wires touching.

This unexpected surge can cause the fuse to blow immediately. Inspect your heat press for any signs of exposed wiring or damage.

Faulty Wiring Or Internal Components

Over time, wiring can deteriorate or internal components may fail. These issues can lead to a short circuit or overload.

Regular maintenance checks can prevent these problems. If they do occur, a professional may need to replace the faulty parts.

Steps To Diagnose A Recurring Fuse Problem

When a heat press keeps blowing a fuse, it may seem puzzling at first. Yet, fixing this problem requires a systematic approach.

Follow these troubleshooting tips to pinpoint the issue. This guide will help restore your heat press to full functionality.

Visual Inspection For Burn Marks

Start by unplugging the heat press. Look carefully for any burnt areas on the plug, cord, or machine. Blackened spots or melted plastic are clear signs of trouble. These may indicate where a surge or heat caused the fuse to blow.

Testing For Electrical Short

Checking for a short circuit is vital. You will need to inspect the heating element and wiring.

Any exposed or frayed wires can cause a short. If you see damaged wiring, it needs immediate attention.

Using A Multimeter To Assess Current Flow

A multimeter comes in handy to measure electrical flow. Place the multimeter probes on either end of the fuse circuit.

A normal reading suggests the current flows well. Anomalies in the reading, on the other hand, are red flags. A consistent methodical approach helps prevent future fuse issues.

Always ensure the machine is disconnected from power before conducting any diagnostic tests to avoid electric shock.

Selecting The Right Fuse For Your Heat Press

Tired of your heat press blowing fuses? The solution could be as simple as selecting the right fuse for your heat press. Fuses are the unsung heroes, safeguarding your equipment from electrical issues. Pick the right one to ensure your creativity never experiences an unexpected halt.

Appreciation Fuse Ratings

Every fuse has ratings that speak to its limits. Grasping these ratings is pivotal. Fuses protect by breaking the circuit when the current exceeds safe levels. Ratings typically include amperes (A) and voltage (V). A correct match prevents unwanted shutdowns.

- Ampere rating: Maximum current a fuse can handle.

- Voltage rating: Maximum voltage at which a fuse can operate.

- Breaking capacity: The highest fault current a fuse can interrupt.

Matching Fuse To Machine Specifications

Check your heat press specifications before purchasing a fuse. Align the fuse’s amperage and voltage ratings with your machine’s requirements.

Overeating can lead to damage while underrating causes unnecessary tripping. Consult the manual or manufacturer for precise specs.

| Heat Press Model | Recommended Fuse (A) | Recommended Fuse (V) |

|---|---|---|

| Model A | 15A | 250V |

| Model B | 20A | 250V |

Quality Fuses Versus Generic Brands

A quality fuse provides optimal protection. Brand fuses often meet strict testing standards, ensuring reliability. Generic brands might offer savings but could lack consistency.

Investing in reputable brands means fewer disruptions and better safety for your heat press operation.

- Brand A: Known for durability and consistent performance.

- Brand B: Offers advanced features such as indicator lights.

Troubleshooting The Power Source And Outlet

Experiencing a heat press that keeps blowing a fuse can halt production and frustrate users. Before assuming the worst, it’s essential to troubleshoot the power source and outlet. Often, the solution is simpler than expected.

Verifying Outlet Voltage And Compatibility

Before diving further, it’s essential to verify that the outlet providing power to your heat press is functioning correctly. Perform the following checks:

- Use a multimeter to measure the outlet’s voltage.

- Compare the reading with the heat press’s voltage requirement.

- Ensure the outlet matches the power needs of your device.

Assessing The Power Cord And Plug For Damage

A damaged cord or plug could be your culprit. Inspect closely for:

- Visible fraying or cuts in the cord.

- Burn marks or melting on the plug.

- Loose connections or bent prongs.

If damage is found, replace the power cord or plug promptly.

Surge Protection And Voltage Regulators

Voltage spikes can blow fuses. Protect your heat press with:

- A surge protector to shield against sudden voltage increases.

- A voltage regulator to maintain consistent power levels.

Utilizing these devices can prevent future fuse issues.

Improving Circuit Capacity For High-demand Machines

Improving Circuit Capacity for High-Demand Machines is vital for any workshop or business relying on heavy-duty equipment. A common issue like a heat press blowing a fuse signifies that the present electrical setup isn’t up to the task.

It’s essential to not just fix immediate problems but ensure the system meets the energy needs of high-demand machines. Let’s investigate solutions to improve circuit capacity and keep your equipment running smoothly.

Dedicated Circuits For Industrial Equipment

In workshops with heavy machinery, dedicated circuits are a must. This means each high-demand machine has its own circuit.

Shared circuits can overload, causing fuses to blow. Let’s break down the benefits of a dedicated circuit for your heat press:

- Prevents Overloading: Dedicated circuits handle one machine’s power demands.

- Improved Safety: Reduces the risk of electrical fires from overburdened wires.

- Better Performance: Assures consistent power for optimal machine operation.

When To Consult A Professional Electrician

Sometimes, an upgrade to your electrical system is necessary. Know when to call a professional electrician:

- If fuses keep blowing, despite using a dedicated circuit.

- When multiple machines are added to your workshop.

- Your current setup fails to meet new equipment energy requirements.

An expert can assess and recommend the right upgrades for safety and efficiency.

Upgrading Your Workshop’s Electrical System

To prevent issues like a heat press blowing fuses, consider these upgrade steps:

| Upgrade Step | Description |

|---|---|

| Inspection | An electrician checks your system’s capacity. |

| Recommendation | They suggest the required improvements. |

| Implementation | Upgrades are professionally installed. |

Remember: Proper circuit capacity is fundamental for running high-demand machines efficiently and safely.

Maintenance Tips To Prevent Overheating

Keeping your heat press in top condition means avoiding the dreaded blown fuse. Regular maintenance reduces the risk of overheating. Simple steps ensure longevity and performance. Follow these tips for a well-functioning heat press.

Regular Cleaning Regimens

Cleanliness is key to cooling. Over time, lint and dust accumulate. They obstruct proper ventilation. This buildup can lead to excess heat. Thus, routine cleaning is a must. Here’s how:

- Turn off and unplug the heat press.

- Wait for it to cool down completely.

- Wipe the surfaces with a soft cloth.

- Use a small brush to remove debris from hard-to-reach areas.

Strategic Heat Press Placement

Adequate space around your heat press prevents overheating. Proper placement improves air circulation. Make sure to:

- Place the heat press on a stable, heat-resistant surface.

- Keep it away from walls and other equipment.

- Ensure there’s enough room for the heat to dissipate.

Preventive Maintenance Checks

Regular check-ups can avert sudden disruptions. A maintenance schedule is essential. It helps identify potential problems before they worsen. Here’s a checklist:

| Frequency | Check |

|---|---|

| Monthly | Inspect electrical cords for damage. |

| Quarterly | Test temperature accuracy. |

| Bi-Annually | Examine the pressure adjustment. |

Heat Press Operating Best Practices

Welcome to the essential guide on Heat Press Operating Best Practices. Maintaining your heat press properly can prevent annoying issues like a blown fuse.

A little know-how goes a long way in extending the life of your equipment and ensuring your projects turn out perfectly. Follow these best practices to keep your heat press running smoothly.

Starting With Lower Heat Settings

Always begin with low temperatures. Your heat press is like your morning coffee – it needs time to warm up.

Jumping straight into high heat can shock the system, leading to overloads and tripped circuits. Here’s what to do:

- Turn on your machine

- Select the lowest temperature setting

- Gradually adjust as the machine warms

This method protects the internal components, ensuring a long-lasting machine.

Gradual Increase In Pressure

Think of pressure like a first date – it’s all about gradual increases. Too much too soon, and you might just blow it – literally. Follow these steps for the right approach:

- Close the press lightly

- Adjust pressure settings bit by bit

- Check the material’s response after each increase

By easing into the right pressure, you avoid overburdening the heat press.

Allowing Time For The Machine To Cool

After a good workout, your heat press deserves a rest. Let it cool down before shutting it off. Here’s a cool-down routine:

- Turn off the heat

- Open the press

- Allow it to sit open for a while

Just like a cooldown after exercise prevents muscle pain, this practice prevents mechanical strain.

Educating Staff On Safety And Usage

When heat presses malfunction and fuses blow, the root cause often traces back to user error or a lack of safety knowledge. Proper education for staff is paramount to prevent such incidents.

Through structured training and protocols, businesses can safeguard their operations and ensure the longevity of their equipment.

Let’s probe the essential steps to prepare staff to handle heat presses safely and effectively.

Training Sessions For Operators

Hands-on training sessions are vital for operators. Regular sessions provide them with the necessary skills. Items covered in training include:

- Machine parts identification: Familiarizing with each component.

- Correct operation procedures: Step-by-step usage guide.

- Maintenance tips: Keeping the machine in top condition.

- Troubleshooting common problems: Quick fixes for minor issues.

Creating A Safety Protocol

A safety protocol acts as a roadmap for safe operations. It details measures such as:

- Personal protective equipment (PPE) usage.

- Clear work area guidelines.

- Equipment checks before starting work.

This protocol should be displayed in the work area for easy reference.

Emergency Measures For Electrical Issues

Being prepared for electrical emergencies is non-negotiable. Staff must know immediate actions to take:

| Issue | Action |

|---|---|

| Blown Fuse | Switch off the machine and report. |

| Power Surge | Disconnect machines if safe to do so. |

| Smoke or Sparks | Evacuate and alert emergency services. |

All employees should take part in regular emergency drills. Actual practice helps reinforce these critical steps.

Professional Repair Or Replacement Decisions

Dealing with a heat press that keeps blowing fuses can throw a wrench in your production schedule.

Deciding between getting a professional repair or opting for a total replacement requires careful consideration.

This part of the blog will guide you through making the right call.

When To Call A Technician

Recognizing the signs that you need a technician’s expertise is key. Here are scenarios indicating it’s time:

- Constant Fuse Failure: If your heat press repeatedly causes fuse blowouts.

- Strange Noises or Smells: Unusual sounds or odors point to a deeper problem.

- Electrical Issues: Flickering lights or tripped circuits when the heat press is in use.

Cost-benefit Analysis Of Repair Versus Replacement

A comprehensive cost-benefit analysis can save you money and downtime. Compare these factors:

| Repair | Replacement |

|---|---|

| Cost of parts and labor | Price of a new heat press |

| Downtime associated with repair | Improved efficiency with new equipment |

| Potential future malfunctions | Warranty and longevity of a new machine |

Upgrading To A More Efficient Model

If repairs are too costly, consider an upgrade. A new heat press might offer:

- Better Energy Efficiency: Reducing operational costs.

- Advanced Technology: Improving quality and speed.

- Warranty Benefits: Peace of mind with manufacturer support.

Assess your business needs and volume demands before investing in a newer model.

Frequently Asked Questions Of Heat Press Keeps Blowing Fuse

Why Does My Heat Press Keep Tripping The Breaker?

Your heat press may trip the breaker due to electrical overload, a short circuit, or a faulty machine. Ensure it’s connected to the correct voltage and is the only appliance on the circuit.

Why Does My Heat Keep Blowing The Fuse?

Your heat might blow the fuse due to an electrical overload, short circuit, or faulty heating unit. It’s essential to address these issues promptly for safety.

How Do You Fix A Fuse That Keeps Blowing?

Identify and resolve the underlying electrical issue causing the fuse to blow. Replace the blown fuse with one of the correct amperages. Ensure not to overload the circuit and check for faulty appliances or wiring. Always consult a professional electrician for complex electrical problems.

Why Does My Heat Press Keep Turning Off When I Plug It In?

Your heat press may turn off due to electrical issues, overheating, faulty wiring, or a defective thermostat. Check your power source and consult the manual for troubleshooting steps.

How Do I Stop My Heater From Blowing Fuses?

To prevent your heater from blowing fuses, first, ensure that the heater is not overloaded by using too many devices on the same circuit. Check for any damaged wiring or components in the heater and promptly replace or repair them to prevent electrical issues.

Conclusion

Wrapping up, and troubleshooting a heat press’s persistent fuse issues requires patience and precision. With the advice provided, you’re now equipped to fix the problem and resume production. Remember, safety first and always consult a professional when in doubt. Stay creative and press on with confidence.