The heat press pressure knob may be stuck due to over-tightening or debris buildup. Solving it involves cleaning the threads or gently loosening it with tools.

Dealing with a stuck heat press pressure knob is a roadblock that can disrupt your garment printing process, creating frustration for both newcomers and seasoned professionals in the printing industry.

Achieving high-quality prints hinges on maintaining consistent pressure, with the pressure knob playing a pivotal role in fine-tuning this aspect.

Neglecting problems like gunk, tightness, or wear can harm the knob, affecting print quality and causing more issues.

To keep your heat press in top-notch condition, it’s crucial to comprehend the common factors contributing to a stuck knob and to be well-versed in straightforward methods for resolving the issue.

Giving prompt and careful attention to the pressure knob ensures that your machine remains at peak efficiency, allowing you to swiftly return to the creation of outstanding heat-pressed designs.

If you find yourself facing a heat press pressure knob stuck situation, taking proactive measures will undoubtedly save you time and maintain the seamless operation of your equipment.

Heat Press Basics: The Role Of Pressure

Working with a heat press machine is like baking a cake. Pressure is like the oven temperature. If it’s not just right, your cake won’t bake well.

For heat pressing, too little or too much pressure can ruin your design. Here comes the pressure knob, your tool for the perfect press.

Importance Of Consistent Pressure In Heat Transfers

Ensuring your heat press operates smoothly is essential for successful heat transfers. One common issue users encounter is a stuck pressure knob.

Let’s sink into the mechanics of heat transfer and understand why maintaining constant pressure is vital.

In the realm of heat exchangers, the pressure plays a pivotal role. The constant pressure heating process, often discussed in thermodynamics, reveals the intricate relationship between pressure and heat transfer. Imagine your heat press as a microcosm of this concept.

When the pressure knob refuses to budge, it disrupts the delicate dance of heat and pressure. To comprehend this, consider the enthalpy and pressure relationship.

In a constant pressure non-flow process, enthalpy change equates to heat transfer, a fundamental principle widely acknowledged in thermodynamics.

Referencing the importance of consistent pressure in heat transfers, the overall heat transfer coefficient becomes paramount.

Picture it as the conductor orchestrating the symphony of heat distribution. Any deviation in pressure disrupts this harmony.

To troubleshoot a stuck pressure knob, delve into the enthalpy as a function of temperature and pressure. The intricate dance of delta u at constant pressure becomes your guide to resolving the dilemma.

Remember, the enthalpy is equal to heat when conditions are met, akin to the heat capacity at constant volume.

unraveling the mystery of a stuck heat press pressure knob involves deciphering the intricate interplay of pressure and heat transfer principles.

By comprehending these nuances, you’ll not only troubleshoot the issue but also improve your understanding of the broader heat transfer landscape.

Perfect pressure means perfect transfers. It’s the secret to making sure your design sticks well and looks great.

Imagine the difference: a T-shirt that turns heads versus one that fades in the wash. Consistent pressure ensures your creations last longer, look better, and keep customers coming back.

Think of it like this:

- Even Pressure: No peeling or washing away of designs.

- Right Pressure: Supreme quality and long-lasting prints.

- Adjusted Pressure: Works on thick or thin fabrics just fine.

Components Of A Heat Press Machine

A heat press has different parts, each important in its way. The pressure knob, a top player, can sometimes get stuck.

Why does that happen? Maybe it’s wear and tear, a build-up of adhesive, or a need for adjustment.

Key parts include:

| Component | Function |

|---|---|

| Platen | The main surface is where you press your design. |

| Pressure Knob | Turns to increase or decrease pressure. |

| Heating Element | Applies heat to the transfer. |

| Control Panel | Sets temperature and time. |

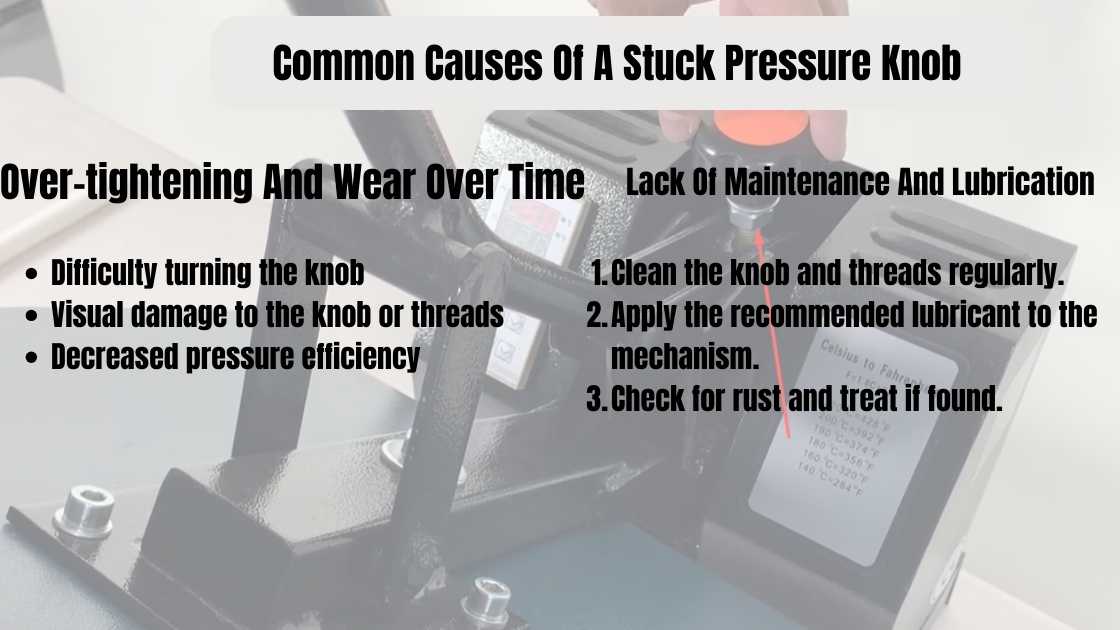

Common Causes Of A Stuck Pressure Knob

Heat press machines are essential for transferring designs onto fabric. But sometimes, the pressure knob might refuse to budge, making the machine hard to use.

This issue can arise from different factors. Let’s dip into the common culprits that can cause this aggravation.

Over-tightening And Wear Over Time

One regular culprit for a stuck heat press knob is over-tightening. Operators might overtighten the knob, believing it ensures a better press. This action can strip the threads or distort the knob.

Time also plays a role. Repeated use of the heat press can lead to wear in the knob mechanism.

Signs of over-tightening and wear:

- Difficulty turning the knob

- Visual damage to the knob or threads

- Decreased pressure efficiency

Lack Of Maintenance And Lubrication

Just like any other machine, a heat press requires regular upkeep. Neglecting maintenance can lead to the knob getting stuck.

Proper lubrication is necessary for the threads and moving parts of the knob. Without it, friction and seizing are inevitable.

Tips for maintenance and lubrication:

- Clean the knob and threads regularly.

- Apply the recommended lubricant to the mechanism.

- Check for rust and treat if found.

Regular cleaning and lubrication keep your heat press in top shape. A well-maintained machine avoids the frustration of a stuck knob.

Remember, it’s vital to address these issues promptly. Ignoring them can lead to more serious damage and costly repairs.

Troubleshooting The Stuck Pressure Knob

Troubleshooting the stuck pressure knob on a heat press is a vital skill for any printing enthusiast. Regular maintenance keeps your machine in top shape, but sometimes, parts can get stuck due to many reasons.

The pressure knob is vital for adjusting the pressure of the heat press, and if it’s stuck, it can disrupt your printing process. Let’s sink into how to fix this issue.

Identifying The Underlying Issue

First, we need to diagnose why the pressure knob might be stuck. It could be due to overuse, lack of lubrication, or accumulation of dirt and debris. Our goal is to pinpoint the cause to apply the correct solution.

Start by inspecting the knob for visible signs of damage or rust. Pay close attention to how it feels when you try to twist it – does it budge at all or is it completely immovable?

Assessing The Knob And Surrounding Mechanism

Next, examine the components connected to the knob. This involves checking the threads, the spring, and the adjustable plate.

Wear and tear on these parts can lock the knob in place. Consider the following steps:

- Unplug the heat press and let it cool down.

- Clean the knob with a soft cloth to remove any dirt.

- Apply a small amount of lubricant oil to the threads.

- Try gently turning the knob to work the oil in.

Refer to the heat press manual for proper maintenance practices to prevent future issues. If after these steps, the knob remains stuck, it might be time to contact the manufacturer for further assistance or consider replacing the pressure adjustment knob.

Diy Fixes For The Pressure Knob

An uncooperative heat press pressure knob is every crafter’s nuisance. Don’t fret, though. You can fix it yourself!

The right DIY tweaks can get your heat press back to peak performance fast. Try these simple but effective solutions.

Simple Lubrication Techniques

A stiff knob often needs just a dab of lubrication. Here’s how to do it:

- Turn off the heat press. Safety first!

- Locate the pressure knob.

- Apply a small amount of machine oil.

- Twist gently to spread the oil.

- Test the knob to see if it moves freely.

Manual Adjustment Tips

Sometimes, the knob needs a little encouragement. Try these steps:

- Power off the device for safety.

- Grasp the knob firmly with both hands.

- Apply gentle pressure in a back-and-forth motion.

- Do not force it if it resists, to avoid damage.

- Check for any visual obstructions or damage.

When To Seek Professional Help

Sometimes a stuck heat press pressure knob needs expert intervention. This guide helps you recognize irreparable issues and find skilled technicians for the job.

Don’t risk further damage to your equipment or your safety. Know when to call in the pros.

Recognizing Unsolvable Problems

Not all problems are DIY-friendly. If you notice the following, professional help is essential:

- Broken components: Cracks or breaks are not fixable with basic tools.

- Electrical issues: Sparks or smoke signal severe risk.

- Severe jamming: Forceful turning could cause more harm.

- Warranty concerns: Unauthorized repairs could void your warranty.

Finding Qualified Repair Services

Choosing the right technician is critical. Follow these steps to ensure quality service:

- Check credentials: Ensure they specialize in heat press repairs.

- Read reviews: Look for high ratings and positive feedback.

- Request a quote: Compare costs but don’t skimp on quality.

- Ask about warranty: A good service will offer a guarantee on repairs.

Most importantly, trust your gut. If a service doesn’t feel right, keep looking.

Preventive Measures For Future

Preventive Measures for Future issues with your heat press are pivotal in maintaining the longevity and performance of your equipment.

Taking proactive steps can save you from the frustration of a stuck pressure knob.

Routine Maintenance Schedule

A consistent maintenance schedule helps prevent equipment failure. Here’s what to include:

- Regular cleaning: Wipe down the machine after use.

- Inspections: Check for loose parts or wear and tear.

- Lubrication: Apply recommended oils to moving parts.

Best Practices For Pressure Adjustment

To avoid getting the pressure knob stuck, apply these best practices:

- Turn the knob gently, avoiding excessive force.

- Adjust pressure while the machine is cool.

- Refer to the manual for specific instructions.

By following these preventive measures, future problems can be significantly reduced.

Understanding Warranty And Manufacturer Support

Dealing with a stuck heat press pressure knob can be challenging. It often requires insights into the warranty and manufacturer support options available.

Knowing these details can help you address the issue with less hassle and potentially at no cost.

Navigating Warranty Claims

When a pressure knob gets stuck, the first step is to check the warranty. Different manufacturers have many policies, so understanding the terms is essential. Here’s a simplified guide:

- Find your purchase receipt or warranty card.

- Read the warranty terms to confirm coverage for the knob issue.

- Contact the support team as instructed in the warranty.

- Provide the necessary details: purchase date, model, and issue.

- Follow the process for claims as guided by the support staff.

Keep all communication polite and concise for a smoother claim process.

Utilizing Manufacturer’s Resources

Most heat press manufacturers offer a range of resources. They usually have websites or helplines to assist. Utilize these resources:

- Search the FAQ section on the manufacturer’s website.

- Download user manuals or troubleshooting guides.

- Find video tutorials for fixing common issues.

- Use online customer service chatbots if available.

Contacting the manufacturer directly can also lead to quick solutions. Their experts may offer step-by-step guidance to resolve the problem.

Alternatives To Traditional Heat Press Machines

Outdated heat press machines sometimes have a pressure knob that gets stuck. This can be frustrating. Better alternatives exist. These machines use advanced technology to avoid this issue. Let’s explore what’s on the market.

Exploring Advanced Heat Press Technologies

New heat press technologies offer improvements. They are more reliable and easier to use. Here are some exciting options:

- Automatic Presses: Touch screens and digital settings.

- Draw Heat Presses: Slide-out platforms for safety.

- Swing-Away Heat Presses: Teflon-coated elements prevent sticking.

Weighing The Pros And Cons

Deciding on a heat press isn’t easy. Here’s a quick list of pros and cons:

| Pros | Cons |

|---|---|

| New Tech | Cost |

| Ease of Use | Learning Curve |

| Safety Features | Size |

Balance these factors to decide. Consider your needs and budget. Choose wisely!

Enhancing Your Heat Printing Business With Reliable Equipment

Running a successful heat printing business requires reliable equipment. Every component matters, especially when it comes to your heat press machine. A common issue users face is a stuck pressure knob.

Proper maintenance and solving equipment issues promptly are key. Let’s dive into how investing in quality and innovation ensures smooth operations.

Investing In Quality For Long-term Success

Quality equipment is the foundation of any thriving business. Choose machines with a robust build and excellent reviews. This reduces breakdowns and increases productivity.

- Regular maintenance keeps machines running smoothly.

- Look for reputable brands with proven track records.

- Check warranties for long-term protection.

When a pressure knob gets stuck, start by consulting the manual for troubleshooting. If it’s a quick fix, you may just need to clean the mechanism.

For persistent issues, contact customer support. A replacement might be necessary for seamless operation.

Keeping Up With Industry Innovations

Adapting to the latest technology can position your business for growth. Stay ahead by:

- Attending trade shows to see new equipment in action.

- Reading industry publications for trends and updates.

- Connecting with other professionals on online forums.

Innovative features to look for:

| Feature | Benefit |

|---|---|

| Auto-release | Less manual effort and increased efficiency. |

| Pressure sensors | Consistent quality for every print. |

| Touchscreen controls | User-friendly interfaces mean quicker setups. |

Remember, investing in quality and innovation improves the durability and efficiency of your equipment. This, in turn, ensures a successful and profitable heat printing business.

Frequently Asked Questions For Why Is The Heat Press Pressure Knob Stuck And How To Solve It

How Do I Fix The Pressure On My Heat Press?

Check your heat press manual for pressure adjustment instructions. Turn the pressure knob clockwise to increase or counterclockwise to decrease until you achieve even, firm pressure. Perform a test press to ensure proper adjustment. Regular maintenance can help prevent future pressure issues.

Why Is My Heat Press Not Pressing?

Your heat press may not press due to a few common issues: inadequate pressure adjustment, faulty heating elements, or malfunctioning time and temperature controls. Check these components and refer to your manual for troubleshooting guidance.

Why Is The Temperature Not Going Up On My Heat Press?

Your heat press may not be heating due to a malfunctioning thermostat, a tripped circuit, or a faulty heating element. Ensure it’s plugged in correctly and check for any visible damage. Contact customer service if problems persist.

How Do You Gauge Pressure On A Heat Press?

To gauge pressure on a heat press, use its pressure adjustment knob until the machine indicates the correct pressure setting, often through a readout or by feeling the resistance when closing the press. Regular testing with a pressure gauge ensures accuracy.

Conclusion

Dealing with a stuck pressure knob on your heat-press need not halt your crafting progress. By employing the solutions outlined, you can quickly resume operations. Remember to perform regular maintenance, ensuring your heat press remains in top condition for creating flawless custom designs every time.

Keep crafting without interruption by mastering these simple fixes.