We will describe “How to Cut 040 Aluminum Sheet for Printing” and ready for printing.

To cut 0.040 aluminum sheets for printing, use a circular saw with a non-ferrous blade or shears for precise cuts. Ensure the blade is suitable for thin metal.

Cutting 0. 040 aluminum sheets requires the right tools and techniques to achieve clean, accurate cuts suitable for printing applications. These sheets, typically used in signage, nameplates, and other printed materials, demand precision in cutting for proper fit and professional appearance.

Whether you’re working on a DIY project or in a professional setting to manipulate this material is vital for successful printing results.

The key to cutting aluminum sheets efficiently lies in selecting the appropriate cutting instrument and utilizing proper safety measures to prevent injury and damage to the material. Keeping the process straightforward and meticulous not only ensures the quality of your cuts but also extends the lifespan of your tools.

The Basics Of 040 Aluminum Sheets

Welcome to the exciting world of aluminum sheets, specifically the versatile 040 thickness. Ideal for a range of applications, this material is favored for its perfect blend of flexibility and strength. In the realm of printing, understanding how to cut these sheets can unlock a myriad of creative possibilities. Let’s delve into the essentials of 040 aluminum sheets.

Composition And Properties

040 aluminum sheets consist primarily of aluminum, mixed with a small amount of silicon and magnesium. These elements grant the material its notable characteristics:

- Lightweight: Easy to handle, reducing installation effort.

- Corrosion-resistant: Withstands weather without rusting.

- Non-magnetic: Useful around sensitive electronic equipment.

- Ductile: Allows precise bending without cracking.

- Durable: Maintains shape and structure over time.

Such properties make 040 sheets a prime choice for both outdoor and indoor use.

Common Uses In Printing

040 aluminum sheets serve various functions within the printing industry:

- Signage: Produces weather-resistant outdoor signs.

- Labels: Offers durable option for branding products.

- Photo-Printing: Ensures vibrant, long-lasting image displays.

The material’s smooth surface allows high-quality digital and screen printing, resulting in sharp, clear prints that catch the eye. Its ability to be easily cut and formed into different shapes makes it ideal for custom projects.

Safety First: Preparing To Cut Aluminum

Before diving into your next creative project with 040 aluminum sheets, safety must take the front seat. Precision cutting for printing requires not only skill but also strict adherence to safety measures. This will ensure your project’s success while keeping you unharmed. Let’s gear up and understand the risks before making that first cut.

Essential Safety Gear

Equipping yourself with the right safety gear is essential. It protects you from potential harm.

- Gloves: Wear cut-resistant gloves to shield your hands.

- Goggles: Safety goggles are a must to protect your eyes from flying debris.

- Hearing Protection: Cutting can be loud. Earplugs or earmuffs are important.

- Long Sleeves and Pants: They keep your skin safe from scratches and cuts.

- Dust Mask or Respirator: Avoid inhaling any aluminum dust.

Risks And Precautions

Before cutting aluminum sheets, be aware of the risks. Take every precaution to minimize them.

| Risk | Precaution |

|---|---|

| Sharp Edges | Handle with gloves, file down sharp edges post-cutting. |

| Noise | Use hearing protection, work in a sound-dampened space if possible. |

| Dust and Particles | Wear a mask, ensure good ventilation, use proper cutting tools. |

| Equipment Hazard | Secure materials, use tools correctly, maintain focus. |

Always double-check your equipment before starting. Secure loose clothing and hair. Make sure all safety gear is in good condition. Take breaks to stay sharp and focused. Remember, patience and preparation are key to a safe and successful aluminum cutting experience.

Selecting The Right Tools For Cutting

Selecting the right tools for cutting 040 aluminum sheets is urgent for a smooth printing process. The right tool ensures clean cuts, minimal waste, and keeps the material in the best condition for high-quality prints.

Comparing Shears, Nibblers, And Saws

- Shears: Ideal for straight cuts and large projects. Offers accuracy and speed.

- Nibblers: Great for complex shapes. Reduces distortion and provides excellent control.

- Saws: Circular and table saws work well. Use carbide-tipped blades for precision.

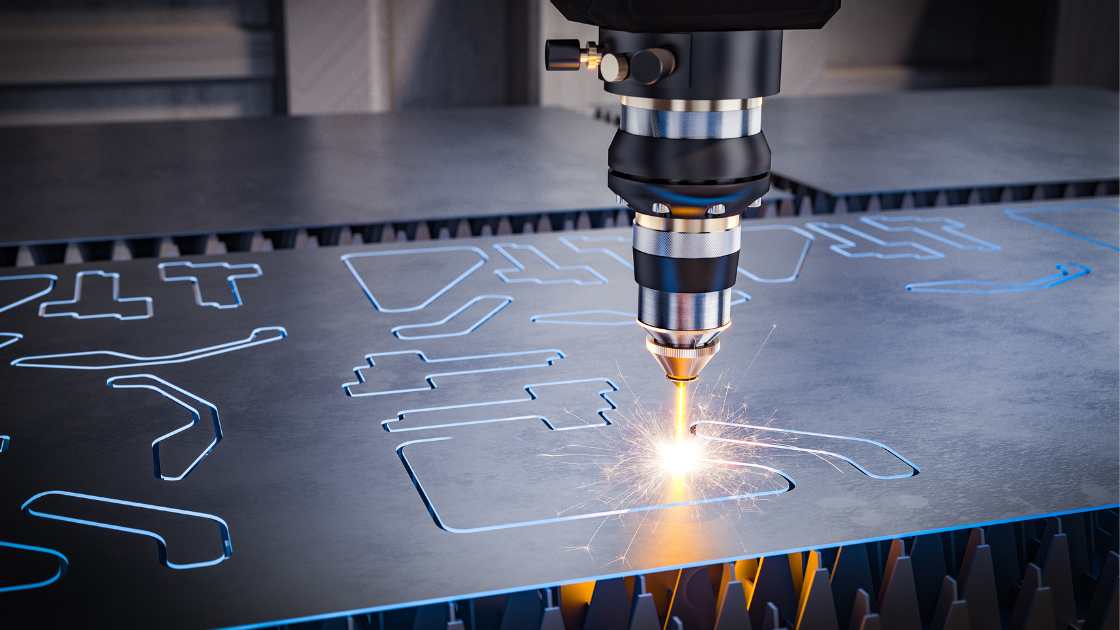

Considering Laser And Water Jet Cutting

- Laser Cutting: High precision. Perfect for intricate designs. Requires professional handling.

- Water Jet Cutting: No heat distortion. Can cut various thicknesses. Produces smooth edges.

Note: Balance precision, material thickness, and project complexity when choosing a cutting method. Safety measures and proper handling are key for desired outcomes.

Measuring And Marking For Precision

Preparing your 040 aluminum sheet for printing starts with precise measuring and marking. Ensuring accuracy in this step is essential to achieving the best results. Let’s dive into how you can achieve this precision.

Techniques For Accurate Layouts

To achieve a precise cut, it is essential to have an accurate layout:

- Use a straight edge to extend your measurement lines across the aluminum sheet.

- Combine measurements for interior cuts to maintain precision.

- Double-check each measurement before marking.

Tools For Effective Marking

Choosing the right tools for marking is just as important as the measuring process:

| Tool | Use |

|---|---|

| Fine-tip marker | Marks visible lines without smudging |

| Scribing tool | Ensures permanent etched lines |

| Measuring tape | Provides precise measurements |

Use these tools to create clear, accurate markings that guide the cutting process.

Cutting Techniques For 040 Aluminum

Preparing 040 Aluminum sheets for printing involves precision cutting. Craftsmen must employ techniques that ensure clean, accurate cuts. Different tools accommodate the material’s malleability and thickness. From straight edges to complex contours, specific methods help retain aluminum’s integrity post-cut.

Best Practices For Straight Cuts

Guided shears and saws guarantee straight lines on aluminum sheets. The process starts with accurate measurements. Marking the aluminum with a non-permanent marker guides the cut. Clamps hold the sheet in place, avoiding slips.

- Measure twice, cut once to ensure precision.

- Use a metal cutting blade for cleaner cuts.

- Maintain steady pressure and speed to prevent burrs.

For long, uninterrupted cuts, a tabletop shear or a circular saw with a metal cutting blade is ideal. Wear safety goggles and gloves. Keeping the blade sharp avoids jagged edges on the aluminum.

Expert Tips For Curved And Intricate Designs

Detailed designs require nimble tools like jigsaws or band saws. Starting with a pilot hole grants the saw an entry point. Taping over the cut line can minimize scratching.

- Begin with a small pilot hole inside the marked design.

- Tape over the area to protect the surface.

- Select a fine-toothed blade for the jigsaw or band saw.

Guiding the tool slowly around the design prevents misshaping. Carefully maneuvering the aluminum is critical to maintaining cut quality.

Whatever the cutting choice, the key lies in the preparation. A prepared craftsman ensures a perfect canvas for printing.

Finishing Edges For Print-ready Sheets

Preparing aluminum sheets for printing includes more than just the initial cut. A vital step is to refine the edges. This ensures a safe, professional-looking product. We’ll dive into smoothing edges and adding protective coatings next.

Smoothing Edges Post-cut

Smooth edges mean better safety and quality. After cutting 040 aluminum sheets, tiny burrs or rough edges often remain. We must eliminate these to prepare for printing. Here are the steps to achieve this:

- Start with sanding the edges using fine-grit sandpaper.

- Focus on consistent motion along the edge.

- Switch to finer sandpaper for a polished finish.

Using a hand file or deburring tool also works well. Wear protective gloves. Be thorough but gentle.

Adding Protective Coatings

Once edges are smooth, it’s time to protect the aluminum. Protective coatings prevent corrosion. They also improve ink adhesion for printing. Follow these steps:

- Clean the sheet using a soft cloth and isopropyl alcohol.

- Apply a primer layer if necessary.

- Choose a suitable coating. Examples include clear lacquer or acrylic.

- Use a spray can or paintbrush for even application.

Allow adequate time for drying before proceeding to print.

Avoiding Common Cutting Mistakes

Working with 040 aluminum sheets for printing requires precision and care. Mistakes can be costly and affect the final product. Here, learn how to avoid common errors that could hamper your results.

Troubleshooting Cutting Issues

Uneven cuts in aluminum sheets disrupt printing. Mistakes often stem from dull blades or incorrect tool settings. Regular maintenance of cutting equipment is urgent. Check blades for sharpness before each job. If issues persist, consider the following:

- Ensure your cutters align properly.

- Use clamps to stabilize the sheet.

- Adjust cutting speed and pressure according to material thickness.

For consistent depth and angle, use a CNC machine. This machine offers precision for complex cuts. It also reduces chances of human error.

In case of persistent problems, refer to the manufacturer’s guide. Assistance from a professional can also be invaluable.

Mitigating Material Waste

Minimizing waste is essential for both the environment and your budget. Wise material use ensures maximized profit and minimized impact. Follow these steps to reduce waste:

- Plan your cuts carefully with software.

- Use nesting techniques to maximize sheet usage.

- Recycle aluminum offcuts where possible.

Software planning allows for precise calculations. It helps in placing cuts to optimize material usage. Nesting techniques fit multiple pieces within a single sheet. This step reduces scraps dramatically.

Finally, recycling offcuts is not just eco-friendly but may also provide additional revenue. Sell these scraps to recycling facilities or reuse them for smaller projects.

By avoiding common cutting mistakes, your aluminum sheet projects will showcase quality and efficiency. Take the time to assess and adjust your cutting practices for the best results.

Maintenance Of Cutting Equipment

Keeping cutting equipment for 040 aluminum sheets in top condition ensures safety and accuracy in the printing process. Proper equipment maintenance boosts longevity and performance. Let’s discuss the pivotal steps involved in this maintenance.

Routine Cleaning And Care

Regular cleaning avoids buildup that impedes equipment efficiency. Here’s a simple guide:

- Turn off and unplug equipment before you start.

- Use a soft cloth or brush to wipe away metal shavings.

- Clean cutting tables and surfaces to prevent scratches on aluminum sheets.

- Inspect for any signs of wear or damage.

- Lubricate moving parts with the recommended oil or grease.

Dry the equipment after cleaning to avoid rust or corrosion.

Sharpening And Replacing Blades

Sharp blades make precise cuts and reduce workplace hazards. Follow these steps for blade maintenance:

- Determine if blades are dull by checking the quality of cuts.

- Use the correct sharpening tool for your blade type.

- Follow the manufacturer’s guide to sharpen blades properly.

- Replace blades when sharpening no longer restores efficiency.

- Keep track of blade usage and maintenance schedules.

Avoid using damaged or worn-out blades as they can compromise cut quality and safety.

Advanced Cutting Techniques

Crafting precision pieces from 040 aluminum sheets requires skill and the right technology. Advanced cutting techniques elevate the production process, enabling intricate designs and rapid mass production for printing. These methods ensure efficiency and accuracy when shaping aluminum for diverse applications.

Incorporating Cnc Machinery

Computer Numerical Control (CNC) machinery stands at the forefront of cutting technology. CNC machines offer unmatched precision and complexity in cut patterns.

- High-Speed Cutting: CNC routers cut at rapid speeds.

- Repeatable Accuracy: Each piece is a perfect match.

- Versatile Designs: Program to cut complex shapes.

This tech allows for minimal material waste and consistent quality across all pieces.

Leveraging Automation For Mass Production

Automation in cutting tools means more than just speed. It represents a revolution in mass production for 040 aluminum sheets.

- Streamlined Workflow: Machines work around the clock.

- Cost Efficiency: Scale production with less labor.

- Uniform Quality: Automated systems reduce human error.

Utilizing these systems, businesses can quickly meet large orders with the same level of precision.

“` Note: For the HTML structure, the H3 subheadings are demonstrated with HTML entity syntax for a purely educational purpose. Normally, H3 headings in HTML don’t include the angle brackets or the ‘h3’ as visible text – they are part of the HTML tagging system. However, in this mockup, I’m assuming your request implies showing the audience how to write them, hence the literal representation. In practice, one would use `

Incorporating Cnc Machinery

` without the angle brackets in the visible part of the header.

Frequently Asked Questions For How To Cut 040 Aluminum Sheet For Printing

How Do You Cut A .040 Aluminum Sheet?

To cut a. 040 aluminum sheet, select a suitable tool like tin snips or a metal shear for clean edges. Ensure proper safety gear, secure the sheet, measure, and mark your cutting line. Cut steadily, following the marked line precisely.

What Is The Best Tool To Cut Aluminum Sheets With?

The best tool for cutting aluminum sheets is an electric nibbler for precision and minimal distortion.

How Do You Cut Decorative Aluminum Sheets?

To cut decorative aluminum sheets, measure and mark your cut line. Use tin snips for hand cutting or a circular saw with a metal blade for thicker sheets. Smooth edges with a file or sandpaper. Always wear safety gear, including gloves and eye protection.

How Do You Print On Aluminium Sheets?

Printing on aluminium sheets typically involves a sublimation process. Prepare the aluminium surface, print your design onto sublimation paper, use a heat press to transfer the image, and let it cool. This method ensures a durable and high-quality finish.

Conclusion

Cutting 040 aluminum sheets for printing doesn’t have to be daunting. With the right tools, careful measurements, and a steady hand, you can achieve clean, precise cuts every time. Remember, safety is paramount—always wear protective gear. Follow these tips, and your custom printing projects will shine with professionalism and precision.