To print inside a mug, use a sublimation printing method with a heat press. Ensure the interior is coated with a special polymer for ink adherence.

Printing on the inside of a mug presents a creative way to personalize drinkware, whether for business branding or adding a personal touch to a gift. The process requires precision and the right equipment, specifically a sublimation printer and a mug press capable of reaching the inside surface.

Companies and individuals alike seek this unique printing option to create memorable and engaging products. This technique’s popularity is rising due to its high-quality, durable results. It makes the interior of a mug just as customizable as the exterior.

Perfect for promotional items or keepsakes, mastering the interior mug printing technique can set businesses apart and delight customers with every sip.

Introduction To Mug Printing

Mug printing has become a popular way to add a personal touch to a daily-use item. Whether for home or office, printed mugs can showcase your style, brand, and message. With recent advances in printing technology, it’s now possible to print detailed images and text inside mugs.

It creates a unique and surprising effect for users. Let’s take a closer look at why personalized mugs are appealing and their common uses.

The Appeal Of Personalized Mugs

Personalized mugs serve as more than just vessels for your favorite drinks. They often reflect personality, commemorate special occasions, or represent favorite causes. The inside of a mug offers a fresh and unexpected canvas for messages and designs that are revealed as the mug is tilted or emptied, giving users a delightful experience with every sip. From photo mementos to inspirational quotes, the possibilities for personalization are endless.

Common Uses For Printed Mugs

| Purpose | Usage |

|---|---|

| Corporate branding | Reinforce brand identity among employees and clients with printed mugs. |

| Marketing giveaways | Popular items for contests, promotions, and freebies at events. |

| Personal gifts | Thoughtful presents for birthdays, weddings, and anniversaries. |

| Souvenirs | Tourist spots and events sell mugs with landmarks or event details. |

| Cafés and restaurants | Establishments create unique mug designs for customer experience and decor. |

Types Of Mug Printing Techniques

Are you ready to make your mugs stand out? There are several ways to print your favorite designs inside a mug. From personal use to business branding, each technique offers a unique touch. Pick the method that suits your style and needs. Let’s dig into the different mug printing methods.

Sublimation Process

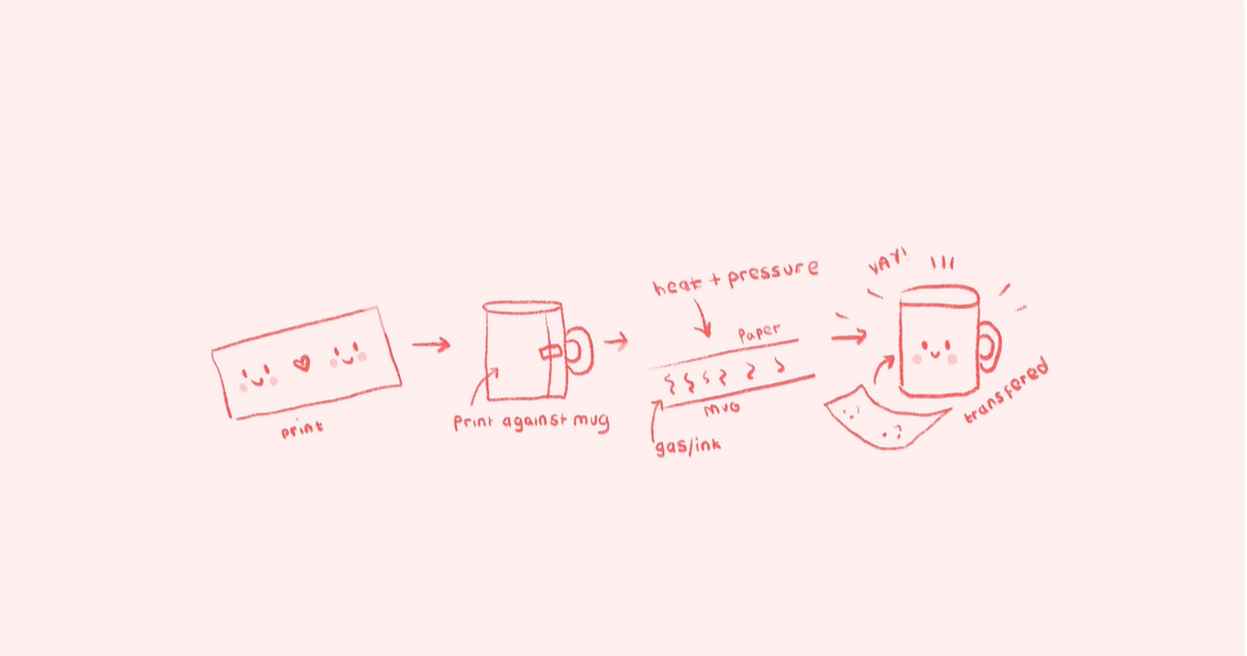

Sublimation printing creates vibrant and detailed images. This technique uses heat to transfer dye onto the mug. Here is how it works:

- The design is printed on special sublimation paper.

- Paper is wrapped around the mug.

- Heat press applies high temperature.

- Ink turns into gas and bonds with the mug surface.

This method is perfect for full-color images and complex patterns.

Screen Printing

Screen printing is ideal for bold and simple designs. It uses stencils and ink. Here’s a quick overview:

- Design is carved out on a screen.

- The screen is placed on the mug.

- Ink is pushed through the mesh onto the mug.

Choose screen printing for high-quality, durable designs.

Pad Printing

Pad printing uses a silicone pad to stamp your design inside the mug. It works well for curved surfaces. Here are the steps:

Pick a design.

Ink cup deposits the ink onto the etched image.

Silicone pad picks up the ink.

Pad presses the design inside the mug.

This method is great for precise and crisp images on differently-shaped mugs.

Materials Needed For Printing Inside A Mug

The craft of printing inside mugs is an innovative way to personalize your drinkware. Whether for a business, a special gift, or personal use, the right materials are crucial for a successful print job. Learn about the essentials you need for printing inside a mug.

Choosing The Right Mug

Selecting the appropriate mug is critical. Consider these factors:

- Material: Ceramic and porcelain are best for sublimation printing.

- Coating: A poly-coating is necessary to transfer images.

- Shape: Straight-walled mugs ensure even image transfer.

Inks And Coatings

The correct ink and coating make the print vibrant and durable:

- Sublimation Ink: Specialized for heat transfer printing.

- Clear Coat: Protects the print from wear and tear.

Printing Equipment

Essential tools for printing inside a mug include:

- Mug Press: Machine designed for cup shapes.

- Heat Tape: Secures the design during transfer.

- Sublimation Printer: For creating the transfer.

Design Considerations

Printing inside a mug adds a surprise element for anyone finishing their drink. Key design aspects ensure longevity, visibility, and impact. These include graphic design, material selection, and color usage. Aim for designs that captivate without compromising mug usability.

Graphic Design Tips

The interior of a mug offers limited space, thus simplicity and clarity are important. Ensure the following:

- Choose bold graphics that stand out against the mug’s color.

- Vector designs keep edges sharp, even when scaled.

- The text should be legible and minimal to fit the curve inside.

- Consider the viewing angle; the design should be visible as you drink.

Selecting Durable Materials

Material choice is vital for longevity and safety. Consider materials that:

- Are food-safe and non-toxic.

- Can withstand high temperatures without degrading.

- Maintain print quality after multiple washes.

- Compatible with the specific printing technology used.

Color Choices And Limitations

Colors add personality to your mug design but come with restrictions:

| Consideration | Details |

|---|---|

| Color Range | Some hues may not be as vibrant inside a mug. |

| Transparency | Clear graphics can be harder to perceive against dark beverages. |

| Fading | UV-resistant inks help prevent color fade over time. |

Select contrasting colors for best visibility and factor in potential color shifts post-production.

Preparing The Mug For Printing

Customizing mugs with unique prints makes them special. Before the actual printing begins, prepping the mug is essential. A clean and primed surface ensures a perfect print. Here’s what you’ll need to do:

Cleaning The Surface

Cleanliness is key for the printing process. Any dust or grime can spoil the print. Follow these steps for a pristine surface:

- Wash the mug with mild dish soap.

- Rinse it thoroughly with water.

- Wipe it dry with a clean cloth.

- Use rubbing alcohol on the surface for extra cleanliness.

Applying A Base Coat

A base coat ensures the print adheres better and lasts longer. It acts as a primer for the surface. To apply a base coat:

- Select a special coating spray made for mugs.

- Spray an even layer over the printing area.

- Allow the coat to dry completely before printing.

Making sure the mug is ready for printing is simple but vital. Follow these steps for an ideal base for mug printing!

Detailed Printing Process Step-by-step

Expertly printing inside a mug can transform it into a personalized keepsake. By understanding each step in the process, anyone can create a custom-printed mug. From aligning the design to curing the print, this guide offers a detailed walk-through.

Aligning The Design Inside The Mug

Proper alignment is key. Follow these steps:

- Choose a design that fits the mug’s inner size.

- Print the design on special transfer paper.

- Clean the mug’s interior for clear adhesion.

- Cut the design closely to minimize excess paper.

- Use heat-resistant tape to hold the design in place.

- Ensure the image is centered and straight.

Temperature And Pressure Settings

Correct settings are important. Use this table as a guide:

| Setting | Value |

|---|---|

| Temperature | 380–400°F (193–204°C) |

| Pressure | Medium to High |

| Time | Approx. 3-5 minutes |

Always check your specific mug press manual for the best results.

Curing The Print

Curing secures the design. Here’s what to do:

- Place the mug in the press.

- Confirm temperature and pressure are set.

- Start the timer and heat for the recommended duration.

- Once complete, remove the mug carefully.

- Peel off the transfer paper.

- Let the mug cool down completely.

The print should now be durable and resistant to washing.

Troubleshooting Common Printing Issues

Custom mugs make fantastic gifts and promotional items, but printing them perfectly can be tricky. Ink smudging, color fading, and image peeling are common issues many encounter. This section digs into how to tackle these challenges head-on. Master the art of mug printing with these simple solutions.

Handling Smudges And Leaks

A clear, crisp image is the goal when printing inside a mug. Smudges and leaks disrupt this. Follow these tips to keep your mugs looking professional:

- Check Your Equipment: Ensure that your printer and any associated equipment are clean and in good working order.

- Quality Inks: Use high-quality sublimation inks designed for mug printing. Low-quality inks often lead to leaks and smudges.

- Proper Handling: Always handle the mugs with care before, during, and after printing to avoid accidental smudging.

- Drying Time: Allow the ink to dry completely before moving or stacking the mugs.

Preventing Fading And Peeling

Over time, a mug’s printed image might fade or start to peel. Preserve the quality and vibrancy with these steps:

- Top-Quality Coating: Ensure mugs have a polymer coating suitable for sublimation. This helps the ink to bond well, reducing fade.

- Correct Heat: Use a heat press with the right temperature and time settings for the mugs you’re printing on.

- Aftercare Instructions: Provide users with tips to care for their mugs, like avoiding dishwashers and harsh chemicals.

By consistently checking equipment, choosing the right materials, and providing aftercare tips, your printed mugs should remain vibrant and smudge-free, gaining happy returns or referrals.

Safety And Maintenance

Printing inside a mug is a delightful way to customize drinkware. It’s essential to prioritize safety and maintenance. Correct procedures ensure a risk-free environment and extend the life of both equipment and the mugs. Follow these tips for a safe practice and to keep your custom mugs looking great for years.

Ensuring Ventilation

Adequate ventilation is crucial when printing inside mugs. Chemical fumes can be harmful if inhaled in large quantities. Always print in a well-ventilated area. Open windows or use a fan. This will disperse fumes and safeguard your health.

Cleaning The Equipment

After each printing session, clean your equipment. Remove ink residue and debris to prevent clogging and maintain print quality. Use a damp cloth for wiping down. Regularly check for ink spills or drips. Proper cleaning prolongs the printer’s lifespan and ensures consistent results.

Long-term Care Of Printed Mugs

For printed mugs, long-term care keeps them looking new. Avoid abrasive cleaners that can damage prints. Hand wash mugs gently. Do not use harsh scrubbers. Use mild detergent and soft sponges. Confirm if the mugs are dishwasher-safe. Care and gentle cleaning preserve the print’s vibrancy and mug’s integrity.

Case Studies

Exploring case studies provides real-world examples and invaluable insight into printing inside a mug. Whether it’s about triumphant outcomes or learning from errors, these studies shine a light on the path to perfecting this craft.

Success Stories

Personalized mugs take center stage in countless success stories.

- DIY enthusiasts boast about using special sublimation techniques for vibrant prints.

- Small businesses thrive by adding custom mugs to their product lines.

- Gift shops report increased sales during the holiday season with high-quality printed mugs.

Each testament highlights not just the final product, but also the careful selection of materials and the use of cutting-edge printing technologies.

| Company | Technique Used | Outcome |

|---|---|---|

| MugMarvel | Sublimation | 30% sales increase |

| Print-a-Cup | Heat transfer | Doubled online orders |

| EcoMugs | Organic inks | Featured in eco-fairs |

Learning From Printing Mishaps

Mistakes in the mug printing process offer valuable lessons for improvement.

- Temperature control issues can lead to fading or distorted images.

- Incorrect pressure applications often result in uneven prints.

- Choosing the wrong type of mug impacts the adherence of the print.

Through trial and error, printers refine their craft and share their knowledge, contributing to a community of expertise that elevates the industry as a whole.

Frequently Asked Questions For How To Print Inside A Mug

How Do You Write On The Inside Of A Coffee Mug?

To write on the inside of a coffee mug, use oil-based paint markers for durability. Clean the surface, sketch your design lightly with a pencil, then trace with the marker. Allow it to dry completely, and if needed, bake the mug as per the marker’s instructions to set the ink.

Can I Personalise my own mug?

Certainly! “Explore your creativity and make every sip uniquely yours with our personalized mug service. Whether it’s a cherished photo, a special message, or a custom design, our mugs are the perfect canvas for expressing your individual style.

How Do You Transfer A Print To A Mug?

To transfer a print to a mug, first print your design on sublimation paper. Then, use heat transfer tape to secure the paper onto the mug. Next, place the mug in a heat press machine and set the recommended temperature and time.

After pressing, peel off the paper to reveal the transferred print.

How do you permanently write on ceramic mugs?

To permanently write on ceramic mugs, one can use specialized ceramic markers or paints designed for this purpose. After applying the chosen medium, baking the mug in an oven at a specified temperature ensures a durable and lasting inscription, making it a personalized and long-lasting keepsake.

What Printer Do I Need To Print On Mugs?

To print on mugs, you need a sublimation printer paired with special sublimation ink and paper. These printers transfer designs onto coated ceramic mugs using heat.

How Do You Print On The Bottom Of A Mug?

To print on the bottom of a mug, use a special pad printing machine designed for curved surfaces. Ensure the print area is clean, apply the ink via the machine, and then cure the ink as required, usually through heat.

Conclusion

Starting on the mug printing journey transforms ordinary drinkware into personalized treasures. We’ve broken down the steps to make intricate designs within your favorite mugs simple. Adopt this creative process and watch as the magic happens in your hands. Ready to impress with every sip?

Start printing and let your mugs tell a story.