Use 45 Or 60 Degree Blade for Vinyl for most standard vinyl-cutting projects. Opt for a 60-degree blade when dealing with thick, dense materials or intricate designs.

Cutting vinyl requires precision and the right tools to achieve the best results. The choice between a 45-degree and a 60-degree blade revolves around the type of vinyl and the complexity of the design.

Selecting the proper blade can make a noticeable difference in the quality of the cut and the ease of weeding.

The 45-degree blade, being the more common choice, is suitable for general use and works well with thinner vinyl materials.

On the other hand, a 60-degree blade excels with thicker and more challenging materials, cutting with heightened accuracy on detailed artwork.

It’s important to match the blade angle with your project needs to enhance cutting efficiency and protect your materials from damage.

The Vinyl Cutting Conundrum

Mastering the art of vinyl cutting feels much like wielding a magic wand. Each project reinvents itself under the precise dance of the cutter. The choice between a 45-degree and a 60-degree blade heavily weighs on the outcome. Let’s demystify this crucial choice for enthusiasts and professionals alike.

Types Of Vinyl

Knowing your vinyl is the foundational step. Two common types exist:

- Adhesive Vinyl: Great for stickers, labels, and decals.

- Heat Transfer Vinyl (HTV): Ideal for fabric applications.

Your blade choice might vary depending on these types. Adhesive vinyl often requires a 45-degree blade for its thin nature. HTV might benefit from a 60-degree blade, slicing through its greater thickness with ease.

Cutting Vinyl 101

| Blade Degree | Material Suitability | Recommended Use |

|---|---|---|

| 45-degree blade | Thin materials | Small text and intricate designs |

| 60-degree blade | Thick materials | Thick fonts and basic shapes |

Both blades come into their own based on the material and design complexity. A 45-degree blade excels in detail, delivering sharp, clean cuts. It’s the go-to for more delicate vinyl. Conversely, a 60-degree blade tackles the challenge of bulkier materials. It cuts deep, perfect for designs lacking the subtlety of fine lines.

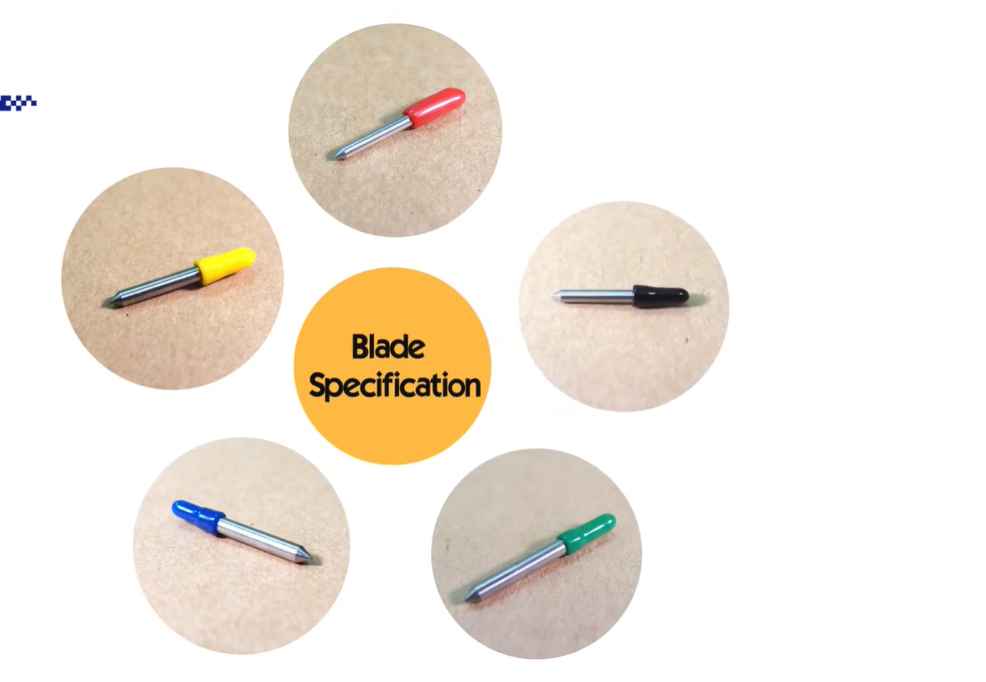

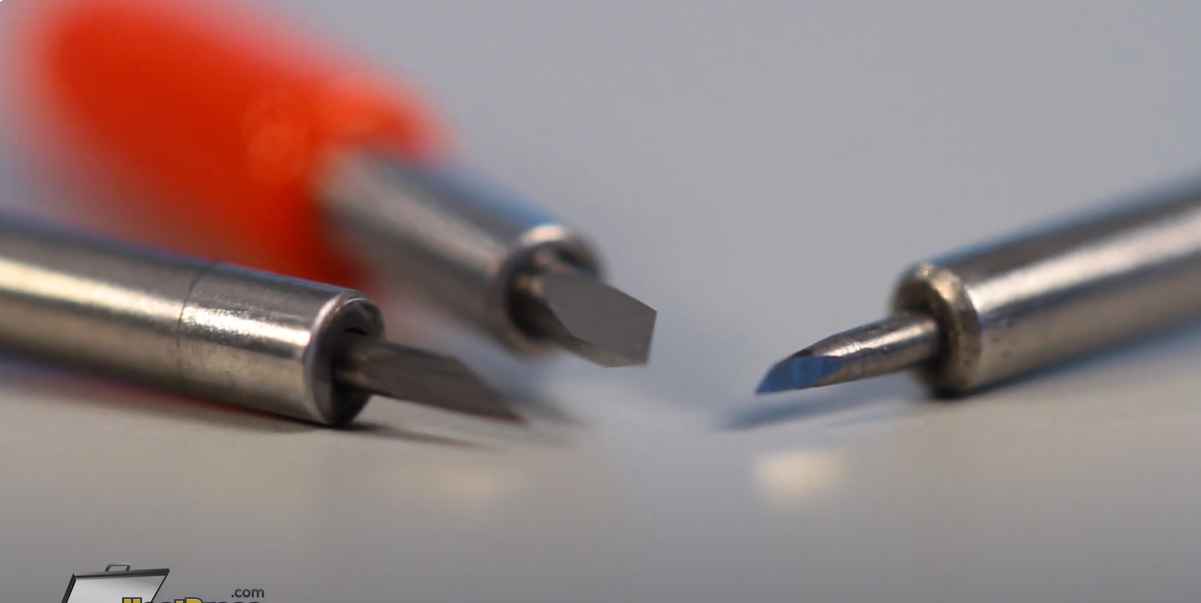

Anatomy Of Vinyl Cutting Blades

The ‘Anatomy of Vinyl Cutting Blades’ is essential to understand for anyone venturing into the art of vinyl cutting. Careful selection of the blade can affect the precision and quality of your cut.

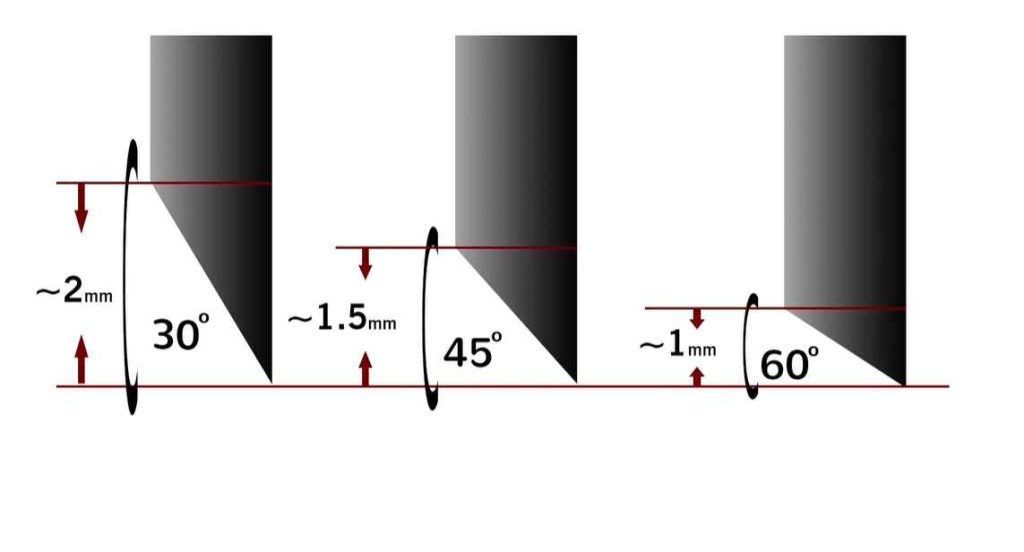

Blade Angles And Their Significance

The angle of the vinyl cutting blade plays a pivotal role in the outcome of your cut. Different angles are suitable for different vinyl thicknesses and detail levels. Let’s explore this further:

- 45-degree blades are common for standard vinyl. They are ideal for general use.

- 60-degree blades can handle thicker vinyl and intricate designs. They cut with more precision.

Material Considerations For Blades

Selecting the right blade material extends the blade’s life and enhances cutting quality. Here are key points:

| Material Type | Benefits |

|---|---|

| Carbide | Durable and stays sharp longer |

| Stainless Steel | Affordable and good for light use |

| Ceramic | Handles high-heat and intense jobs |

Always remember to choose a blade material that suits your project’s needs.

45-degree Blades: The Popular Choice

When diving into the world of crafting with vinyl, the 45-degree blade is often the go-to tool for enthusiasts and professionals alike. This blade has earned its reputation for its versatility and precision. Let’s explore why the 45-degree blade stands out in the crafting community and where it excels the most.

Ideal Uses For The 45-degree Blade

The 45-degree blade shines with typical vinyl projects. It’s the perfect match for cutting standard vinyl and heat transfer materials. Here are some key applications:

- Standard vinyl cutting for decals and signage

- Heat transfer vinyl for custom apparel

- Detail work that requires accuracy

- Paper crafts with clean, crisp edges

Pros And Cons

Like any tool, the 45-degree blade comes with its advantages and limitations. Here’s a quick breakdown:

| Pros | Cons |

|---|---|

| Great for general use | Not ideal for thick materials |

| Precise detailed work | May require more pressure |

| Perfect for thin materials | Less durable for heavy use |

In essence, the 45-degree blade is a trusted friend for most vinyl-cutting jobs. It’s easy to handle and excels in producing clean cuts on a variety of materials.

Despite its limitations with thicker materials, its precision makes it a top pick for crafters.

60-degree Blades: When To Make The Shift

Choosing the right blade for vinyl cutting can elevate the outcome of your project. 60-degree blades are often the perfect accessory for intricate designs or thicker materials. Know when to switch to these precise tools for improved efficiency and finesse.

Specialized Applications

Understanding the niche for 60-degree blades is crucial. These blades handle specialized applications adeptly:

- Thick Materials: Ideal for cutting through thicker vinyl and reflective materials with ease.

- Detailed Artwork: The sharp angle allows for clean cuts on intricate patterns, providing crisp edges.

- Small Fonts: When working with tiny text, a 60-degree blade ensures legible and exact cuts.

Advantages Over 45-degree Blades

The benefits of using 60-degree blades over their 45-degree counterparts are compelling:

| 60-Degree Blade | 45-Degree Blade |

|---|---|

| Better for thick and dense materials | Commonly used for standard vinyl |

| Superior for intricate and fine details | Best for larger, less detailed graphics |

| Excellent with small text and delicate fonts | Good for general text and images |

Consider the shift to 60-degree blades when project precision is non-negotiable and your material is challenging. The right tool can make all the difference, and 60-degree blades deliver every time.

Comparing Cut Quality

When working with vinyl, the cut quality can make all the difference. The right blade angle plays a crucial role in the precision and appearance of the final product. 45-degree and 60-degree blades offer different benefits.

Understanding these can help achieve the best results. Let’s dive into how each blade performs in terms of precision and handling various materials.

Precision And Details

For intricate designs and small letters, a 45-degree blade is often preferred. Its sharp angle allows for cleaner cuts and smoother corners.

Compare that to the 60-degree blade which is designed for thicker materials and larger designs. It may not handle detailed work with the same finesse.

- 45-degree blade: perfect for fine detail and small text.

- 60-degree blade: better for basic shapes and less detailed graphics.

Handling Thick And Thin Materials

Thickness can be a challenge in vinyl cutting. Each blade angle addresses different material characteristics. A 45-degree blade effortlessly cuts thin vinyl, while a 60-degree blade is more suited to thick or dense materials. Selecting the right blade ensures maximum efficiency and minimizes waste.

- 45-Degree Blade– Ideal for standard vinyl.

- 60-Degree Blade– Handles specialized vinyl types like reflective and flock.

Impact On Vinyl Cutter Performance

Choosing the right blade for a vinyl cutter is crucial. It determines the quality of the cut and the lifespan of both the blade and the machine.

The angle of the blade, such as 45 or 60 degrees, plays a pivotal role in this context. Therefore, understanding the impact of blade angle on vinyl cutter performance is a must for both hobbyists and professionals.

Machine Compatibility

Not all vinyl cutters are compatible with every blade angle. Generally, 45-degree blades are standard and widely accepted across various models. These blades are ideal for cutting standard materials like vinyl and paper.

On the other hand, 60-degree blades may only fit specific machines. They are typically used for thicker materials. Always check the manufacturer’s specifications to ensure the blade matches the vinyl cutter.

Wear And Tear Considerations

Blade longevity affects overall performance. A 45-degree blade will wear out differently than a 60-degree one due to the material type and thickness it regularly cuts.

While a 45-degree blade is perfect for thin materials and tends to have a longer life for such tasks, using a 60-degree blade on thicker materials reduces wear.

This specificity ensures that the blade does not degrade prematurely, which could diminish cutting accuracy and require frequent replacements.

| Blade Angle | Material Compatibility | Lifespan Consideration |

|---|---|---|

| 45 Degree | Thin materials like vinyl, paper | Longer lifespan for light-duty cutting |

| 60 Degree | Thicker materials, detailed designs | Reduced wear on heavy-duty cutting |

Ultimately, the right blade angle ensures the cutter operates at its best, maintains precision, and offers reliable cutting for various projects.

Proper blade selection maximizes efficiency and protects your investment in the long run.

Expert Recommendations

Deciding on the right cutting blade for vinyl projects is crucial for precision and efficiency. Whether you are a hobbyist or a professional, understanding the optimal blade angle is paramount. Here we dig into expert recommendations to unveil whether a 45 or 60-degree blade will elevate your vinyl cutting experience.

Industry Standards

The choice between a 45 or 60-degree blade primarily hinges on the vinyl type and the complexity of the design. Industry standards typically suggest:

- 45-degree blades are universal for standard vinyl.

- 60-degree blades excel with thick or detailed vinyl.

Most machines come with a 45-degree blade as it handles a wide range of vinyl cutting tasks.

Professional Insight

Professionals who master vinyl cutting emphasize that choosing a blade is more art than science. They provide insights based on real-world experience:

- 45-degree blades offer better versatility for everyday use.

- 60-degree blades ensure cleaner cuts for intricate designs.

| Material Type | 45-Degree Blade Use | 60-Degree Blade Use |

|---|---|---|

| Standard Vinyl | Recommended | Not Necessary |

| Detailed Designs | Possible | Ideal |

| Thick Material | Not Suitable | Preferred |

In essence, consider the project’s requirements before selecting a blade.

User Experiences And Feedback

Choosing the right blade for cutting vinyl is crucial. It affects the precision and outcome of your work. Many users have shared their experiences on whether to use a 45-degree or a 60-degree blade. Let’s dig into actual case studies and get a feel for the community’s preferences.

Case Studies

Several crafters and professionals have tested both blades under various conditions. The results are worth noting.

- Detail Work: A user reported that for intricate designs, the 45-degree blade was superior.

- Thick Materials: Another found that the 60-degree blade cut through thicker vinyl more effectively.

- Longevity: Users noted that 60-degree blades seemed to last longer, providing more value.

These findings help to match the blade to the task at hand. They are summarized in the following table:

| Task | 45-Degree Blade | 60-Degree Blade |

|---|---|---|

| Small Details | Optimal | Less Efficient |

| Thick Vinyl | Less Effective | Optimal |

| Durability | Average | High |

Community Preferences

The debate between 45-degree and 60-degree blades is ongoing. The community has shown clear preferences.

User forums and social media polls reveal a tendency. For everyday vinyl projects, the 45-degree blade is often chosen. For specialty materials or dense projects, the 60-degree blade wins favor. Here’s a snapshot of the percentages:

- Everyday Use: 45-Degree Blade – 70%

- Specialty Materials: 60-degree Blade – 55%

- Professional Use: 50/50 split between both blades.

These preferences give a clear picture of what might work best for various projects. They reflect years of knowledge and experimentation within the crafting community.

Making Your Choice: Factors To Consider

Welcome to the essential guide for choosing between a 45 or 60-degree blade for vinyl cutting projects.

Making the right choice may seem daunting, but it’s all about considering the nature of your project and the materials you have at hand.

Project Requirements

Understanding the specifics of your project is crucial. The 45-degree blades are versatile and ideal for general use, especially for thin vinyl and fine detail work.

On the other hand, the 60-degree blades are designed to handle thicker materials and more intricate designs with precision. Consider the following:

- Material thickness: Thicker vinyl requires a 60-degree blade.

- Detail levels: For fine details, a 45-degree blade may be superior.

- Cutting depth: Ensure the blade matches vinyl depth requirements.

Cost And Availability

Blade cost might influence your choice. Generally, 45-degree blades are more common and budget-friendly. They are widely available and often come as standard with cutting machines. Contrastingly, 60-degree blades can be pricier and less common. Assess these factors:

| Blade Type | Cost | Availability |

|---|---|---|

| 45 Degree | Lower | High |

| 60 Degree | Higher | Medium |

Always check with your supplier for the most cost-effective and readily available options that fit your project needs.

Frequently Asked Questions Of Should You Use 45 Or 60 Degree Blade For Vinyl

What Degree Blade Is Best For Vinyl Cutting?

For vinyl cutting, a 45-degree blade is generally the best choice for most vinyl types and provides precise cuts and optimal performance.

What Is the 60-degree Blade Used For?

A 60-degree blade is designed for cutting thicker materials with precision, such as flocks, twill, and dense materials in vinyl cutting applications.

What Is The Best Blade To Cut Vinyl?

The ideal blade for cutting vinyl is a 45-degree carbide blade, designed for precision and durability in vinyl cutting tasks.

What Blade Do You Need For Vinyl?

For cutting vinyl, use a standard 45-degree blade for most vinyl types. For thicker materials, opt for a 60-degree blade.

Conclusion

Selecting the right blade angle is crucial for precision in vinyl cutting. A 45-degree blade excels with thin materials, while a 60-degree option is your ally for intricate designs and thicker vinyl. Remember, success lies in matching blade to material for impeccable cuts.

Happy crafting!