Yes, you can sublimate on plastic if it is treated with a special polymer coating. The coating allows the sublimation ink to bond with the plastic material.

Sublimation on plastic is a unique process that enables vibrant, full-color images to be transferred onto plastic surfaces. This digital printing technique is popular for creating personalized items and promotional products.

By using heat-sensitive inks, the sublimation process turns the inks into gas, which then bonds to the polymer-coated plastic, creating a durable and long-lasting image.

The sublimation technology is perfect for a variety of applications, from custom phone cases to branded merchandise.

Since the process requires a careful selection of plastic and precise temperature control, proper Perception and equipment are essential to achieve professional results.

The Basics Of Sublimation Printing

The world of custom printing constantly evolves, introducing versatile techniques like sublimation printing.

This method offers vibrant prints that last longer without peeling or fading. An intriguing aspect of sublimation is its compatibility with different materials, which begs the question: Can you sublimate on plastic? Let’s explore the fundamentals.

What Is Sublimation?

Sublimation is a printing process where heat turns solid dye into gas without passing through a liquid state.

This gas bonds with polymers in the substrate resulting in a durable and detailed print. Its distinctive feature is the seamless transition from solid to gas.

Materials Suitable For Sublimation

Certain materials make ideal candidates for sublimation. The list primarily includes:

- Polyester – Perfect for vibrant and lasting prints.

- Poly-coated items – Allows sublimation on many products.

- Specific plastics – Must be poly-coated for successful printing.

Plastics vary widely in their composition. Not all plastics can handle the heat required for sublimation.

The plastic must be designed to be sublimation-friendly, often called ‘sublimatable’ plastic, which is pre-treated with a special polymer coating.

| Material | Sublimation-Compatible |

|---|---|

| Polyester Fabric | Yes |

| Poly-coated Mugs | Yes |

| Regular Plastic | No |

| Poly-coated Plastic | Yes |

Plastic And Heat Transfer: A Complex Relationship

Many wonder if they can sublimate designs onto plastic. This process requires a perception of how plastic interacts with heat. Sublimation involves high heat to transfer dyes.

Not all plastics can handle this. Some might melt or warp. Others disfigure beyond recognition. Let’s unpack the nature of plastic and its reactions to heat, especially in sublimation.

Characteristics Of Plastic

Plastic comes in different forms. Each with unique properties. Some are rigid and durable. Others are flexible and lightweight. Before attempting sublimation, one must consider these characteristics:

- Thermal Stability: The ability of a plastic to maintain its form at high temperatures.

- Surface Porosity: Determines how well the dye will adhere during sublimation.

- Chemical Composition: Influences interaction with sublimation dyes.

Heat Sensitivity Of Different Plastics

Not all plastics are equal in facing heat. They fall into two major categories:

| Plastic Type | Heat Tolerance |

|---|---|

| Thermosetting Plastics | Resist high temperatures. |

| Thermoplastics | Soften or melt when heated. |

For sublimation, one must choose plastics that can withstand high heat without deforming. Identifying the right type of plastic is essential for a successful transfer.

Sublimation On Plastic: Possibilities And Limitations

Sublimation is a popular method for transferring designs onto different materials. Plastic sublimation brings unique challenges.

It’s essential to understand which plastics can take the heat and hold a vibrant design from the process.

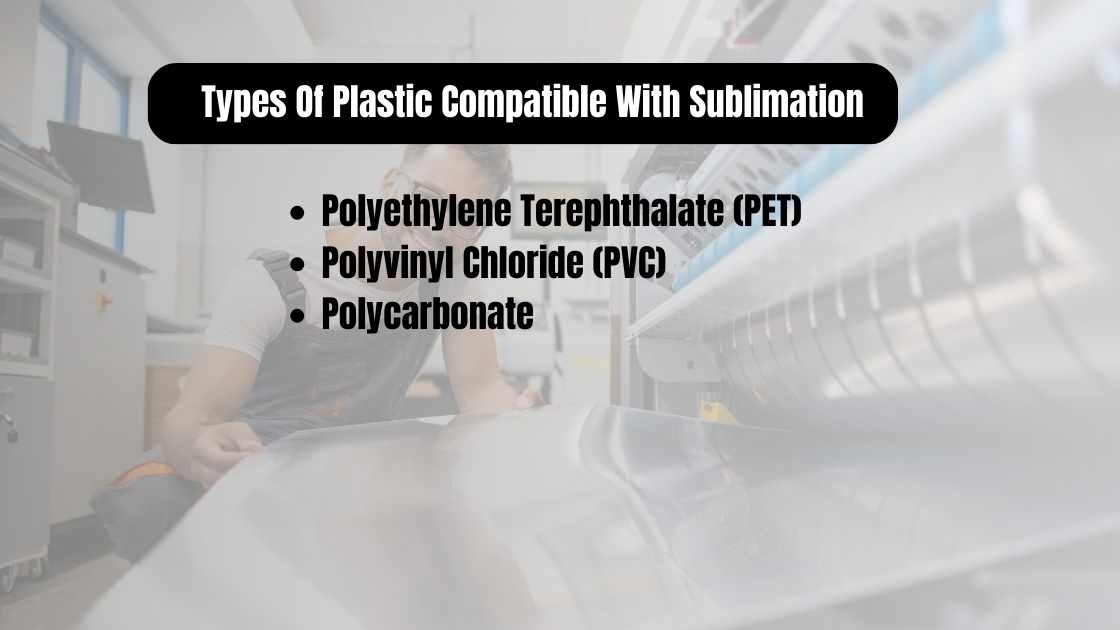

Types Of Plastic Compatible With Sublimation

Not all plastics can handle sublimation. The key is heat resistance and a special coating.

- Polyethylene Terephthalate (PET): Often used because it can withstand high temperatures needed for sublimation.

- Polyvinyl Chloride (PVC): Suitable for sublimation with a proper coating.

- Polycarbonate: A durable plastic that sublimates well when prepared with a special coating.

Challenges In Sublimating On Plastic

Creating lasting designs on plastic is not straightforward. The process is riddled with potential hiccups.

| Challenge | Details |

|---|---|

| Heat Sensitivity | Plastics can warp or melt. Use the right temperature. |

| Surface Preparation | The plastic surface must have a polymer coating for the ink to adhere. |

| Equipment Requirements | Specific sublimation printers and presses are necessary. |

Preparing Plastic For Sublimation Printing

Preparing plastic for sublimation printing is a key step in achieving vibrant and durable designs on items such as phone cases, keychains, and more.

To ensure the sublimation process is effective, proper preparation is essential. Let’s sink into how you can prepare the plastic surfaces for optimal sublimation results.

Surface Treatment

Starting with a clean surface is critical for sublimation success. Follow these steps for optimal preparation:

- Clean the plastic with isopropyl alcohol to remove oils and debris.

- Apply a polymer coating if the plastic isn’t already sublimation-ready. This coating will help in transferring the design seamlessly.

- Allow the coating to dry completely before proceeding.

Remember, the smoother the surface, the clearer your final print will be.

Choosing The Right Sublimation Ink And Paper

Your choice of ink and paper can make a significant difference. Consider these points:

| Ink Type | Paper Type | Compatibility with Plastic |

|---|---|---|

| Special sublimation ink | High-quality sublimation paper | Must be compatible with polymer-coated plastics |

Using the right ink and paper ensures vibrant colors and longevity for the printed design. Make sure your materials align for the best results.

Step-by-step Guide To Sublimating On Plastic

Welcome to our step-by-step guide on how to sublimate on plastic – a process that lets you transfer vibrant designs onto plastic items for a lasting and durable finish.

Whether you’re a hobbyist or a professional, this guide will walk you through the necessary steps to succeed in sublimating your designs onto plastic surfaces.

Creating The Design

Choosing a compatible design is the first vital step. Ensure that your image is high-resolution and suited for sublimation.

Graphic design software can help you customize and adjust your design before printing.

To prepare for printing:

- Open your design in the software.

- Adjust the size to fit the plastic item.

- Invert the image if required. This is necessary for the image to appear correctly post-transfer.

- Select a printer equipped with sublimation ink.

- Print on sublimation paper, ensuring to use of the correct paper profile for optimal color output.

The Sublimation Process

With your design ready, it’s time to transfer it onto the plastic. Ensure the plastic is specifically coated for sublimation.

- Clean the plastic surface with rubbing alcohol to remove any oils or residues.

- Secure the printed design onto the plastic with heat-resistant tape.

- Set the heat press to the recommended temperature, usually around 350-380 degrees Fahrenheit.

- Press for the advised time, which can range from 45 seconds to several minutes based on the plastic’s thickness.

- Wear gloves to protect your hands when removing the item from the press.

Post-sublimation Steps

After pressing, some essential steps ensure the longevity and quality of your sublimated plastic.

- Let the item cool to prevent burns and possible image distortion from handling.

- Carefully remove the sublimation paper to reveal your design.

- Inspect the design to ensure clarity and proper transfer.

- Use a clear sealant spray to provide extra protection, if needed.

- Allow the item to cure – this may take some time, depending on the plastic.

Case Studies: Successful Sublimation Projects On Plastic

Welcome to our exploration of sublimation on plastic through real case studies. Discover how innovators are pushing the limits with their projects.

Innovative Uses Of Sublimated Plastic

Sublimation, a process to transfer designs, brings plastic to life. From promotional items to functional art, the possibilities sparkle.

- Branded Water Bottles: Using sublimation, companies create vibrant and long-lasting logos on plastic bottles.

- Customized Phone Cases: Artists turn plain cases into masterpieces, with each design as permanent as it is unique.

Common Mistakes To Avoid

Sublimation on plastic can be tricky. Here’s what to watch out for:

- Wrong Plastic Type: Not all plastics can handle sublimation. Always choose a polymer that can endure the heat.

- Inadequate Prepping: A clean surface is essential. Any dirt or oils can ruin the transfer.

- Incorrect Temperature: Too hot and the plastic may warp. Too cool and the design won’t adhere.

Future Of Sublimation On Plastic

The Future of Sublimation on Plastic is teeming with potential. As technologies progress, so do the methods and materials we use. The scope is vast and exciting, especially for those keen on innovation in printing and personalization.

Technological Advancements

Recent breakthroughs have unlocked new possibilities in sublimation printing on plastic. Cutting-edge printers and special coatings have emerged. These allow for better image transfer to plastic surfaces. The industry is rapidly moving towards:

- High-resolution printing that rivals traditional methods

- Adaptable sublimation processes compatible with a variety of plastics

- Faster production times, enhancing efficiency and turnaround

Eco-friendly Sublimation Solutions

The move towards sustainable practices has become essential. The sublimation industry is no exception. Innovators are creating solutions that are not only effective but also kinder to our planet. These include:

| Eco-Innovation | Benefits |

|---|---|

| Biodegradable plastic substrates | Reduce environmental impact |

| Recycled plastic options | Promote a circular economy |

| Water-based inks | Lessen chemical usage |

Together, these advancements signal a promising future for the sublimation of plastic products. These trends not only enhance quality but also bolster eco-friendly practices globally.

Frequently Asked Questions On Can You Sublimate On Plastic? (explained)

Does Sublimation Work On Plastic?

Sublimation printing typically requires a polymer-coated or polyester surface. Most standard plastics don’t support sublimation. Special plastic materials designed for sublimation can accept the ink and provide effective results. Always check the substrate’s compatibility before attempting the process.

What Materials Can You Not Sublimate On?

Sublimation printing does not work on 100% cotton, non-polyester fabrics, dark-colored materials, and non-coated metals. It also fails on materials that cannot withstand high heat.

Can You Sublimate On Clear Plastic?

Sublimation on clear plastic is not typically possible, as the process requires a special coating to transfer the image. Most clear plastics lack this coating, making sublimation ineffective.

What Temperature Does Plastic Sublimate At?

Plastic sublimation temperatures vary by type, generally ranging from 100 to 260 degrees Celsius (212 to 500 degrees Fahrenheit).

Can I sublimate on PVC?

Yes, sublimation is not recommended on PVC (Polyvinyl Chloride) as the high temperatures involved in the sublimation process may cause the PVC material to deform or release harmful fumes. It is advisable to choose alternative materials that are suitable for sublimation printing.

Can you sublimate on polyethylene plastic?

Sublimation, a process where a substance transitions from a solid to a gas without passing through the liquid phase, does not apply to polyethylene plastic. Polyethylene has a high melting point, making it unsuitable for sublimation, which typically involves lower temperature transitions.

Conclusion

Sublimation of plastic is possible with the right materials and techniques. It allows for vibrant, long-lasting designs. Always select suitable plastic and use proper sublimation processes for the best results. Experimentation can lead to perfect customization. Hold the creativity sublimation on plastic offers to your projects!