Sublimation Red is Orange due to shifts in color phase under specific conditions. This chromatic change involves the transformation of solid red dye to gas.

Mastering the science behind sublimation is crucial, especially for industries reliant on dyeing fabrics using this method.

The color change can be surprising, yet it’s a predictable outcome within the sublimation process.

This process, often utilized in creating vibrant prints on materials, requires precise temperature control.

Any variation can alter the final hue of the product. Our guide digs into the fundamental reasons behind the red-to-orange transformation, ensuring you grasp the essential principles that drive this phenomenon.

Whether you’re a printing aficionado or a curious learner, comprehending the underlying factors can enhance your expertise in material processing and color dynamics.

The Phenomenon Of Sublimation

The Phenomenon of Sublimation captivates with its magical transition. Materials change state without becoming liquid.

Remarkably, this process can cause unexpected color shifts. These shifts add a twist to creating custom designs, especially on fabrics.

Understanding this can elevate the quality of your design outcomes.

Sublimation Explained

Sublimation seems like magic. Solid materials turn directly into gas. They skip the liquid phase. Heat and pressure play key roles here.

Common in printing, sublimation locks in vibrant colors and sharp images into materials.

Key Points:

- Direct change: Solids become gas.

- Heat: Necessary to trigger sublimation.

- Pressure: Assists the solid-to-gas transition.

Color Shifts In Sublimated Materials

Sublimation can be tricky. Reds might turn to orange. It’s baffling but true. The reasons are scientific.

They involve heat sensitivity and dye behavior under intense conditions.

Reasons for Color Shift:

| Factor | Effect on Colors |

|---|---|

| Heat Sensitivity | Colors alter at high temperatures. |

| Dye Properties | Some dyes change hue when sublimated. |

The process is complex. Yet, understanding it ensures vivid, accurate colors in your projects.

Experiment with fabrics and inks. Testing helps find the best match for true color representation.

Chemistry Behind Color Changes

Discover the surprising science behind color shifts where sublimation red turns orange.

This phenomenon, a marvel to both chemistry enthusiasts and the curious mind, emerges from molecular behavior under varying conditions, challenging our perception of steadfast colors.

Colors are like a language spoken by nature, and they tell us a lot about the world. Sometimes colors change right before our eyes for reasons grounded in chemistry.

Like a chameleon changing its color, certain materials can alter their hues with temperature shifts.

Why does sublimation red look orange? It’s all down to the fascinating interplay of molecules and light, as well as how we perceive these changes with our very own eyes.

Molecular Interaction With Light

Color happens when light interacts with molecules. These molecules absorb some colors and reflect others.

With sublimation, solid turns into gas, and its molecules get excited by energy. This energy changes how they interact with light.

Think of energy as a dance, and molecules change their moves depending on the tune.

Different moves can make red seem orange. It’s all about light and those lively little molecules.

- Energy Absorption: Molecules absorb specific energy, affecting color.

- Light Reflection: Molecules reflect light; we see the remaining color.

- Energy Influence: Heat changes molecular energy and thus color.

Thermal Dynamics And Color Perception

Temperature can play tricks on our eyes, making colors shift in thrilling ways. When stuff gets heated, it can change from one form to another — like ice to water.

This is called sublimation in chemistry. But why does this make red look orange? It’s about how warmth affects the way light bounces off and then into our eyes.

Warmth makes molecules move more, causing red to shift toward orange. It’s like cranking up the heat makes the color dance differently.

| Temperature | Molecular Movement | Color Perception |

|---|---|---|

| Low | Slow | Stable Color |

| High | Fast | Shifted Color |

Remember, what you see is color perception. Your eyes and brain work together to make sense of light. As colors subtly change with heat, our brains decode these signals, often surprising us with an orange tinge in place of red.

- Heated material changes state and behavior.

- Molecular movement alters how light is absorbed and reflected.

- Our eyes and brains re-interpret these changes, seeing different colors.

Sublimation Processes In Industry

The world of industrial printing and production stands on the robust shoulders of numerous processes. Among these, sublimation holds a prized status.

This transformative process takes materials from solid to gas, skipping the liquid phase. Just why is it so popular? It’s a method favored for its precision and lasting results, particularly in color applications.

Dye-sublimation Printing

Dye-sublimation printing is a star in the printing galaxy. It uses heat to transfer dye onto various materials, like fabric or plastic.

In this digital age, the tech syncs perfectly with our love for vivid graphics and durable goods that stand the test of time and wear.

- Crisp Images: The prints show high levels of detail.

- Color Richness: Colors are deep, vibrant, and eye-catching.

- Longevity: The result? Images that won’t wash away or fade fast.

Advantages Of Sublimation For Textiles

The textile industry loves sublimation for its sheer versatility and excellence:

| Advantage | Description |

|---|---|

| Seamless Design | Designs blend without heavy edges. |

| Color Durability | Wash all you want; the colors stay true. |

| Eco-Friendly | Less dye and water equals a happy Earth. |

| Flexible Application | Apply to clothes, bags, flags, and more. |

Factors Influencing Sublimation Results

Factors that affect how a design looks after sublimation are crucial to understand.

Sometimes, red turns to orange. This can surprise many. But it’s not magic! It’s science. Let’s explore why this happens and how to get the best results.

Temperature And Pressure Variables

Getting the temperature and pressure right is like baking a perfect cake. Too hot or too cold, and your design might not look right. Here are key points to remember:

- Correct Temperature: Set the heat press to the dye’s ideal temperature.

- Even Heat: The whole design needs the same amount of heat to look even.

- Right Pressure: Too much pressure can blur your image. Too little means it might not stick well.

Type Of Dyes And Substrates

The choice of dyes and surfaces plays a big part in color outcomes. Keep these facts in mind:

- Quality of Dyes: High-quality dyes give more accurate colors.

- Polyester-Coated Surfaces: These surfaces grab and hold the dye better. This means clearer images.

Why Red Turns To Orange

Have you ever wondered why red sometimes turns orange? Colors can trick our eyes. Things can change depending on how we look at them.

Spectral Analysis Of Color Change

Color shifts happen because of light. Light is part of something called the electromagnetic spectrum.

This spectrum has all kinds of light, including colors our eyes can’t see. Our eyes use this spectrum to see colors.

- Sunlight shows all colors. This mix makes white light.

- When sunlight hits an object, the object takes some colors and bounces others back.

- Red objects bounce red light. They keep other colors.

- If red light mixes with other colors, we might see orange.

Different lights make colors look different. Sometimes, red looks more orange under certain lights.

Real-world Examples Of The Shift

Let’s look at some real-life events that redshifts to orange.

- Sunsets: The sky changes colors at sunset. Daylight has lots of blue. But at sunset, blue scatters away. Red and orange appear more.

- Leaves in Fall: Leaves turn orange in autumn. Chlorophyll goes away. Then red and yellow show more.

- Art: Artists mix colors. They blend red and yellow to make orange.

We find orange where red mixes with light and environment. It creates a warm, glowing effect.

Color Fastness In Sublimated Fabrics

Color Fastness in Sublimated Fabrics is crucial for maintaining vibrant colors. Sublimation, a printing technique, ensures designs don’t wash out or fade.

But sometimes, colors shift, like red becoming orange. Understanding and preventing this keeps fabrics looking bright and as intended.

Ensuring Color Stability

Ensuring color stability in sublimated fabrics is a must. High-quality dyes and correct sublimation processes are key. Here’s how to keep colors true:

- Use premium inks – Quality inks resist fading.

- Control temperature – Correct heat ensures proper dye bonding.

- Opt for synthetic fibers – They hold sublimation inks better.

- Test before production – Verify color outcomes with samples.

Preventing Unwanted Hue Transitions

To stop colors, like red, from turning orange, follow these steps:

- Maintain a consistent workflow – Uniform procedures avoid variability.

- Check your equipment – Ensure printers and presses are accurate.

- Store materials properly – Keep inks and fabrics away from direct light or heat.

- Use a color-fixing agent – It locks in the dye after printing.

Optimizing Sublimation For Desired Outcomes

Ever noticed how red turns to orange in sublimation printing? This color shift can puzzle anyone. Perfect hues make or break a design. Understanding the process unlocks vibrant, lasting prints.

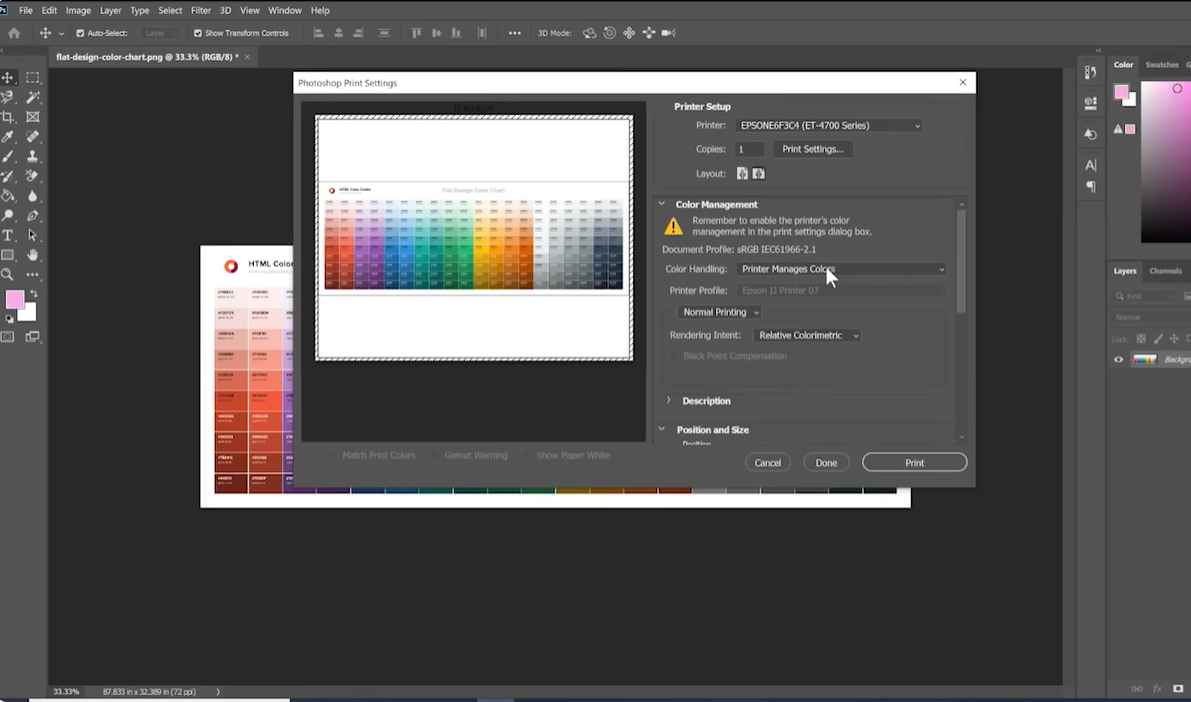

Controlling Sublimation Conditions

To achieve true-to-life colors, controlling the sublimation environment is key. Precise temperature and time mean fewer surprises.

- Temperature: Set the heat press correctly to avoid color variance.

- Time: Longer or shorter than needed? Colors could change.

- Pressure: Consistent pressure ensures even color application.

Fabric type also plays a role. Polyester blends behave differently from pure polyester. Test prints help dial-in settings.

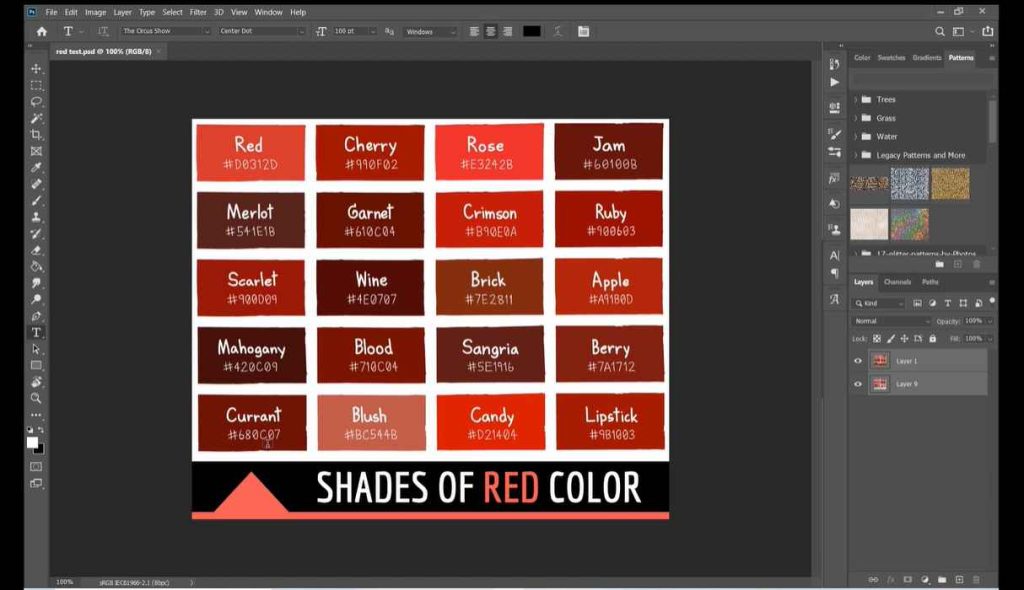

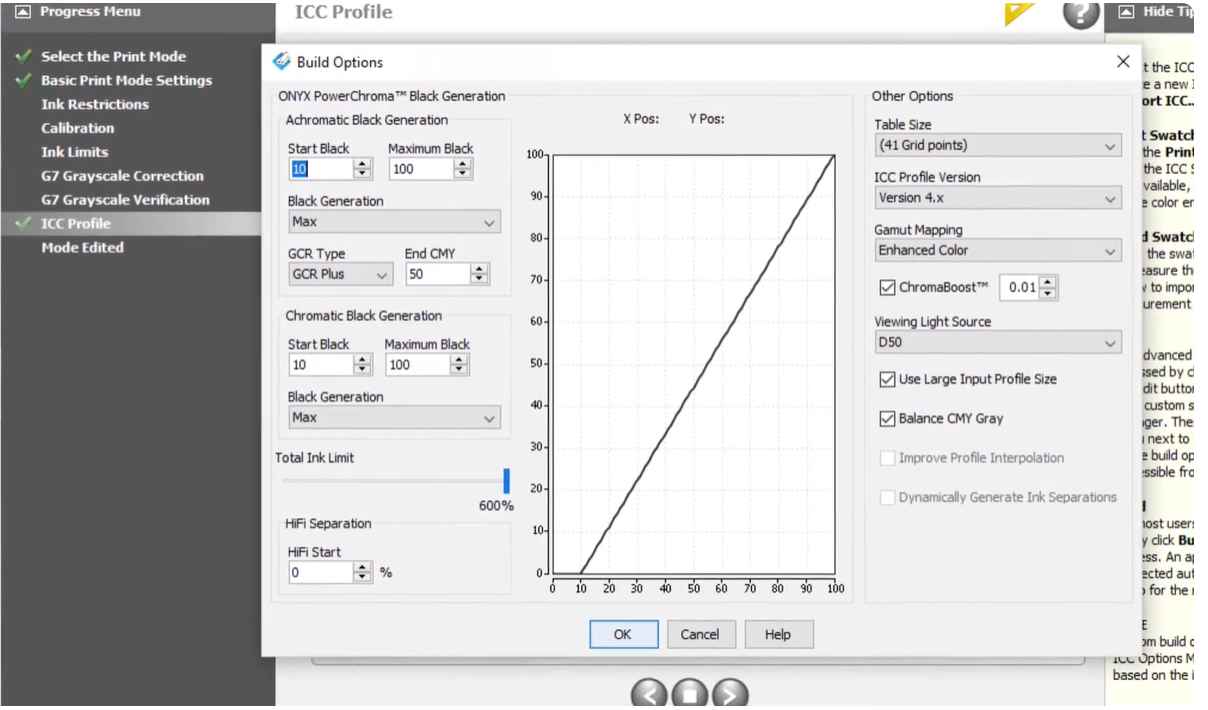

Customization Of Color Profiles

Every printer is unique. Custom color profiles ensure your red stays red, not orange.

- Calibrate your printer. Get the color right from the start.

- Profile creation: Tailor the ICC profile to your printer and ink.

- Test: Print swatches to refine the profile.

Software tools adjust colors before printing. With trial and error, vibrant and accurate prints are within reach.

Challenges And Solutions In Sublimation Printing

In the world of sublimation printing, achieving the perfect color can be a true test. The process, which relies on turning dyes into gas that bonds with polymers, sometimes yields unexpected results.

Red turning to orange is a common concern. Printers seek solutions to ensure their creations match their vision.

Here’s an exploration of the trials faced in color accuracy and the advancements that promise consistent, vibrant results.

Common Issues With Color Accuracy

Color shifts in sublimation printing result from various factors. Notably:

- Printer calibration: Devices need regular checks to stay true to design specs.

- Substrate quality: Lower-grade materials lead to faded colors.

- Ink purity: Contaminated inks can alter expected outcomes.

- Heat press consistency: Even heat is crucial for accurate color transfer.

These issues can make red appear orange, disappointing clients and artists alike.

Innovations For Improved Consistency

Technology and practice advancements bring hope:

- ICC profiles: Custom profiles guide printers to color precision.

- High-end substrates: Quality materials enhance color retention.

- Advanced inks: Formulas are refined for truer colors on the press.

- State-of-the-art printers: New models manage heat and pressure better.

With these innovations, printers can say goodbye to colors gone awry and hello to perfection.

The Future Of Color In Sublimation Technology

Ever wondered why sometimes red prints out orange in sublimation? It’s a common puzzle that ties directly to the future of color in sublimation technology.

This technology is rapidly evolving, giving rise to vibrant, accurate colors that were once thought impossible.

Let’s explore the advancements that promise to revolutionize the way we see color in sublimated products!

Emerging Techniques For Enhanced Quality

Behind the scenes, scientists and engineers work tirelessly to perfect sublimation processes. The result? Enhanced quality and awe-inspiring accuracy. Here are some techniques for breaking new ground:

- Advanced Ink Formulas: These provide a wider color gamut and ensure red stays true to its hue.

- Improved Print Heads: They offer finer detail and better ink flow, so colors blend seamlessly.

- Harnessing Big Data: Data-driven insights tailor the sublimation process for consistent outcomes.

Predicting And Influencing Color Trends

Predicting the next big color trend is like looking into a crystal ball. Nevertheless, sublimation technology is leapfrogging into predictive analytics.

Sublimation experts use data to forecast and influence what hues hit the market.

This interplay of prediction and technology ensures that red doesn’t turn orange unless it’s a fashion statement!

| Technique | Function | Impact on Color Trends |

|---|---|---|

| Color Management Software | Enhances color matching and consistency | Drives precision in replicating trending colors |

| 3D Sublimation | Allows for all-over printing | Enables intricate designs with multiple colors |

| AI Predictive Models | Forecasts color popularity | Influences production choices ahead of trends |

Frequently Asked Questions On Sublimation Red Is Orange (here’s Why)

Why Is My Sublimation Red Look Orange?

Your sublimation red may appear orange due to incorrect color profiles, low-quality ink, or using the wrong transfer paper or substrate. Adjust your printer settings and ensure you’re using high-quality materials for accurate color representation.

Why Is My Red Ink Printing Orange?

Your red ink may print orange due to low ink levels, a clogged nozzle, or incorrect color settings. Check your printer’s ink supply, run a cleaning cycle, and verify the color configuration to resolve the issue.

Why Is My Sublimation Printer Printing Wrong Colors?

Your sublimation printer may print wrong colors due to incorrect color profiles, low ink levels, clogged nozzles, or outdated printer drivers. Ensure proper color management settings and regular printer maintenance for accurate color output.

How Do I Make My Colors More Vibrant When Printing Sublimation?

Use high-quality sublimation ink and a compatible printer. Print on coated sublimation paper for better transfer. Adjust your printer settings to high-quality output. Preheat the substrate to ensure strong color transfer. Properly time and temperature your heat press for optimal vibrancy.

Conclusion

Exploring the color shift from sublimation red to orange is intriguing. This phenomenon stems from science and perception alike. It highlights how light and materials interact, shaping our visual experiences. Remember, the art of sublimation isn’t just science—it’s a dance of hues before our very eyes.

Embrace this colorful journey and its vibrant surprises.