If you thinking about Which Are the Different Heat Press Temp for Dri Fit Shirts. then don’t worry about it, I am going to talk about are Different Heat Press Temp for Dri Fit Shirts.

For Dri Fit shirts, heat press temperatures typically range from 270°F to 300°F. The exact temperature may vary based on the thickness of the material and the heat press machine.

Creating personalized Dri Fit shirts involves precise heat application to ensure the perfect transfer of designs without damaging the fabric.

Known for their moisture-wicking properties, Dri Fit shirts require a lower heat press temperature compared to regular cotton garments to prevent scorching.

Navigating the correct settings on your heat-press is crucial for the longevity of the shirt and the quality of your design.

As a staple in sportswear and active apparel, these garments require a heat press process that accommodates their unique blend of materials.

Therefore, understanding the balance between enough heat to adhere to graphics and avoiding excessive heat that could compromise the shirt’s integrity is essential.

Enthusiasts and printing businesses alike prioritize this knowledge to achieve a durable and vibrant finish on their custom apparel.

Introduction To Heat Pressing Dri Fit Shirts

Heat-pressing Dri Fit shirts are a popular method for creating custom apparel. Dri Fit is a unique material known for its ability to wick moisture away from the body.

This technology makes the fabric highly desirable for sports teams and fitness enthusiasts.

The correct heat press temperature and timing are crucial to ensure the design’s durability without damaging the shirt.

This section will dig into how to effectively apply graphics to Dri Fit shirts.

The Rise Of Dri Fit Technology

The term ‘Dri Fit’ refers to a revolutionary fabric technology developed to keep individuals dry and comfortable. It has gained massive popularity across various sectors, from casual wear to professional sports attire. Understanding this material’s composition is key to mastering the heat press process for Dri Fit shirts.

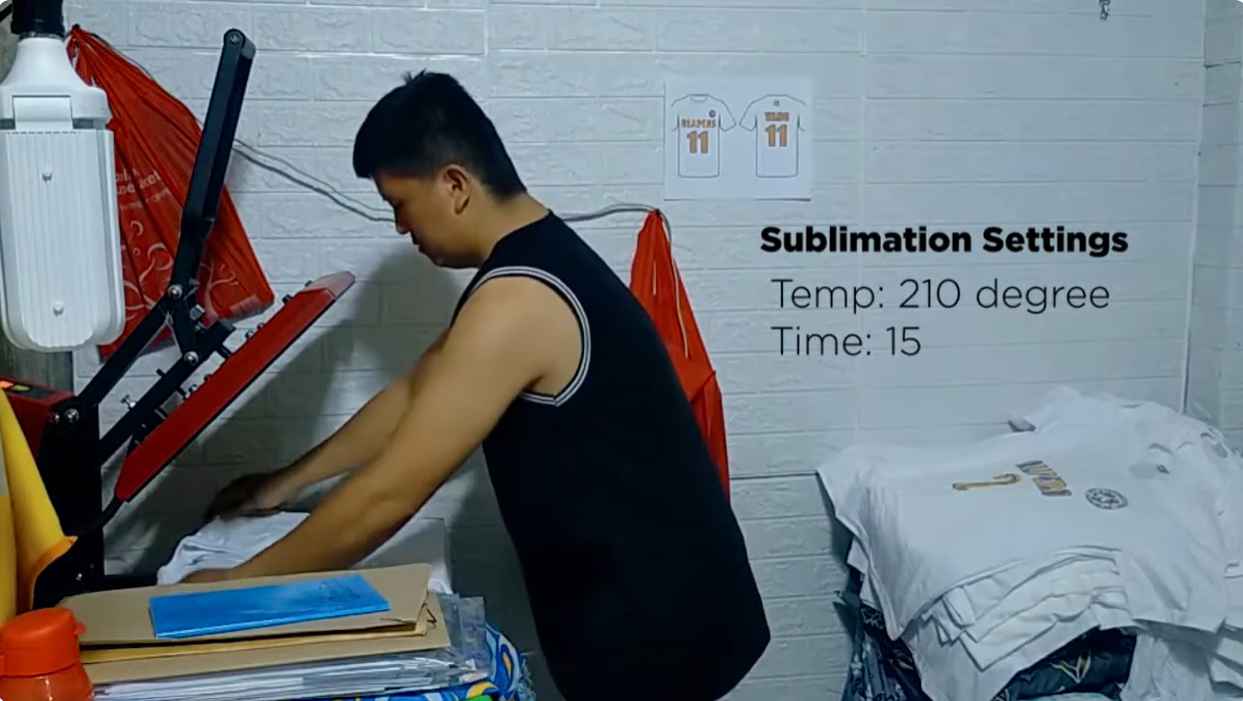

Basics Of Heat Press Application On Synthetic Fabrics

Heat pressing on synthetic fabrics like Dri Fit requires specific considerations. Synthetic materials are sensitive to high temperatures. Thus, it’s essential to use an appropriate temperature to avoid melting or scorching.

An optimal temperature range for Dri Fit shirts is often between 270°F to 300°F. Moreover, the time and pressure applied are critical to ensure a successful transfer. Follow these steps for the best results:

- Set the heat press to the recommended temperature for Dri Fit.

- Pre-press the garment to remove moisture and wrinkles.

- Place the design on the shirt and press for the suggested time.

- Peel the transfer paper if necessary, based on the type of vinyl.

It’s vital to consult with heat transfer vinyl (HTV) manufacturers for the specific heat settings for their products.

Understanding Dri Fit Material

Dri Fit is a high-tech fabric designed to wick away sweat. It helps athletes stay dry and comfortable. This magical material is not just any cloth. It has a special way of dealing with moisture.

That’s vital when pressing designs onto Dri Fit shirts. Getting it right means understanding the material itself.

Composition Of Dri Fit Fabric

Dri Fit fabric is mostly made from polyester. It also has a bit of elastane sometimes. This blend makes it stretchy. Plus, it’s lightweight. Its unique mix lets sweat pass through easily. It dries super fast!

Challenges With Heat Pressing Dri Fit

Pressing onto Dri Fit can be tricky. The heat needed to transfer designs might damage the fabric. It is delicate. Its sweat-wicking features can suffer if the heat is too high. So can its smooth surface. The right temperature is key. It should not be too hot.

- Always use a lower temperature. This can prevent damage.

- Avoid direct heat. Use a cover sheet or parchment paper to protect the fabric.

- Test first. Always do a small test on the fabric. This ensures the right settings.

- Don’t rush. Dri Fit needs gentle care. Let it cool before peeling off the transfer.

Note: Every Dri Fit shirt may have different needs. Manufacturers will give the best advice. Check with them for the perfect settings.

Prepping Dri Fit Shirts For Heat Press

Personalizing Dri Fit shirts with a heat press requires careful prep work. Proper cleaning and positioning are key steps in the process. They ensure crisp, professional-grade prints. Stick to the correct heat press temperature settings for the best outcomes.

Cleaning And Preparation Tips

Before pressing designs onto Dri Fit shirts, it’s essential to start clean. Follow these simple steps:

- Wash the shirt to remove any residues or oils.

- Dry it thoroughly to avoid moisture affecting the press.

- Inspect for any lint or fibers; use a lint roller if needed.

Positioning And Alignment For Optimal Results

Correct placement ensures your design looks professional. Remember these tips for best results:

- Center the design on the shirt using a ruler or T-square for guidance.

- Pre-press the shirt for 3-5 seconds to remove creases and moisture.

- Use heat transfer pillows or pads to ensure even pressure.

Heat Press Temperature Guidelines For Dri Fit

Finding the perfect heat press temperature for Dri Fit shirts is crucial. These garments require specific settings for optimal print quality. Let’s go through the temperature guidelines to prevent damage and achieve stellar results.

Ideal Temperature Range

Dri Fit shirts need a balanced heat level to transfer designs effectively.

| Fabric Type | Temperature | Time | Pressure |

|---|---|---|---|

| Polyester Dri Fit | 270°F – 300°F | 10-15 seconds | Medium |

| Blend Dri Fit | 275°F – 305°F | 10-15 seconds | Medium |

Always check manufacturer recommendations before heat pressing.

Consequences Of Incorrect Temperature Settings

Using the wrong temperature can harm your Dri Fit shirts.

- Too Hot: May cause melting or scorching.

- Too Cool: Might lead to incomplete design transfer.

- Inconsistent Heat: Creates uneven prints or peeling.

Monitor the heat press closely. Use a thermometer to check accuracy.

Time And Pressure Settings

Understanding the time and pressure settings is crucial for perfecting Dri Fit shirt presses. These settings vary depending on material sensitivity and design requirements. Precision in duration and pressure ensures a vibrant, lasting print without damaging the fabric.

Duration Of Heat Application

The right duration is key for a successful transfer. Below are general guidelines for Dri Fit shirts:

- Pre-press the garment for 3-5 seconds to eliminate moisture and wrinkles.

- Apply the design for 15-30 seconds.

- Use a medium to firm pressure setting.

- After pressing, wait a few seconds before peeling off the transfer, based on its type—hot or cold peel.

Adjusting Pressure For Dri Fit Material

Adjusting pressure properly protects the Dri Fit material. Follow these steps:

- Turn the pressure adjustment knob on the heat press to modify the pressure.

- Test the pressure by pressing your hand on the plate. It should be firm but not overly tight.

- For accurate results, use a pressure testing tool if available.

- Remember, too high pressure can damage Dri Fit fabrics.

Special Considerations With Colors And Prints

Special Considerations with Colors and Prints when using a heat press on Dri Fit shirts are essential to maintain the quality and appearance of the garment.

Dri Fit shirts, known for their moisture-wicking properties, often come in vibrant colors and with intricate prints.

Ensuring the correct heat press temperature and technique is critical to preventing damage to both the fabric and designs.

Managing Heat Press With Colored Dri Fit Shirts

Colored Dri Fit shirts require attentive handling while applying heat. The synthetic fibers in Dri Fit material can react poorly to excessive heat, causing discoloration or fading. To maintain the shirt’s vibrant hues, it’s important to:

- Use a lower temperature setting, typically around 280-320 degrees Fahrenheit.

- Test a small area first to ensure the color doesn’t change.

- Limit the time the shirt is under the press, generally 15-20 seconds.

- Use a heat press pillow or pad to distribute the heat evenly.

Protecting Prints And Designs

Prints and designs add personality to Dri Fit shirts but are sensitive to heat. To shield these elements from damage:

- Choose a suitable transfer paper that corresponds with the shirt’s fabric.

- Adjust pressure settings to be lighter for thin or delicate designs.

- Cover the design with a Teflon sheet to protect it during the heat press.

- Peel the transfer paper off carefully to not disturb the print.

Remember, each print may require different temperatures, so refer to the transfer paper’s guidelines for the best results.

Troubleshooting Common Issues

Printing on Dri Fit shirts with a heat press comes with challenges. But worry not! Common problems have solutions. This section will guide you through quick fixes for frequent issues like scorching and uneven transfers. Keep your Dri Fit shirts looking sharp!

Addressing Scorching And Melting

Dri Fit fabrics are delicate. High heat can damage them. Notice scorching? Your press may be too hot. Follow these steps:

- Lower the temperature. Check the shirt’s care label for the maximum heat limit.

- Shorten the press time. Try a quick press, often under 15 seconds.

- Test first. Always do a small test press on a similar fabric.

- Use a heat press pillow or pad. It protects the shirt during pressing.

Remedying Uneven Transfers

Uneven transfers can ruin a shirt’s look. Here’s how to fix them:

- Ensure even pressure. Adjust your heat press to apply uniform force.

- Check the platen. It should be flat against the shirt. Any gaps can cause issues.

- Pre-press the shirt. This removes moisture and creases, allowing a smooth transfer.

Follow these tips for vibrant, flawless designs on your Dri Fit shirts every time. Happy pressing!

Maintaining Dri Fit Shirts Post-press

After mastering the perfect heat press temperature for Dri Fit shirts, it’s essential to focus on the proper care post-press. Ensuring that these garments are well-maintained can greatly extend their life and keep designs looking sharp.

Post-press Care Instructions

Proper post-press care maintains the quality of your Dri Fit shirts. Follow these simple steps:

- Wait before washing: Let the print set for at least 24 hours.

- Turn inside out: Wash the shirt inside out to protect the design.

- Cold water is key: Use cold water to prevent print fading.

- Gentle cycle: Select a mild cycle to reduce wear on the fabric.

- Avoid strong detergents: Use mild detergents to avoid damage.

- Skip the dryer: Air dry the shirt away from direct sunlight.

- No ironing: Ironing directly on a print can ruin both the iron and the design.

Ensuring Longevity Of Heat-pressed Designs

Following specific care tips will keep heat-pressed designs vibrant:

- Avoid bleach and fabric softeners: These can degrade the print.

- Lay flat to dry: This prevents the design from stretching.

- Storage matters: Keep shirts in a cool, dry place.

By following these instructions, Dri Fit shirts with heat-pressed designs can look new for years.

Frequently Asked Questions For Which Are The Different Heat Press Temp For Dri Fit Shirts

What Is The Optimal Heat Press Temperature For Dri Fit?

The optimal heat press temperature for Dri Fit shirts is generally between 270-300°F. It’s crucial not to exceed these temperatures as Dri Fit is often made from synthetic fibers that are heat-sensitive and could melt or deform under excessive heat.

How Long Should Dri Fit Be Heat Pressed?

For Dri Fit shirts, the heat press duration should be around 10-15 seconds. Consistent pressure and time prevent damage to the shirt’s moisture-wicking properties, ensuring the garment maintains its functionality and print quality.

Can You Use A Heat Press On Dri Fit Material?

Yes, you can use a heat press on Dri Fit material, but it’s important to use a lower temperature and shorter press time compared to cotton. Always use a Teflon sheet or parchment paper as a protective barrier between the heat plate and the fabric.

What Are The Risks Of Incorrect Heat Press Settings For Dri Fit?

Incorrect heat press settings for Dri Fit can cause scorching, melting, or warping of the fabric. This not only ruins the garment’s appearance but also its performance properties. Always adhere to recommended temperatures and times.

Conclusion

Mastering the correct heat press temperatures for Dri-Fit shirts is crucial for quality custom apparel. We’ve covered optimal settings for various materials, ensuring vibrant, long-lasting designs. Remember to test, as heat sensitivity can vary. Mastery of these temperatures will elevate your heat press results, leading to flawless Dri-Fit creations every time.

Happy pressing!