Sublimation yellow may appear green due to improper color calibration or heat press temperature issues. To solve it, recalibrate your printer and check for consistent heat press temperatures.

Sublimation printing allows for vibrant, full-color designs on various materials. It’s a fantastic way to produce high-quality prints for garments, mugs, and more. Yet, sometimes the process doesn’t go as planned, and colors can be misrepresented. Specifically, shades like yellow can take on an unwanted green hue, causing frustration for designers and printers alike. Now let’s describe “Why Does Sublimation Yellow Looks Green?”

This discoloration can stem from a range of factors, including printer calibration, color profiles, or even the substrate itself. The technical aspects of sublimation printing is key to troubleshooting these color issues. By keeping equipment well-maintained and following precise printing guidelines, you can ensure that the resulting prints meet your expectations. Remember, high-quality results in sublimation printing are achievable with attention to detail and the proper setup.

Color Shift In Sublimation Printing

Sublimation printing is a popular technique for transferring vibrant designs onto materials. Yet, sometimes, colors shift unexpectedly. This can lead to frustration when a yellow turns greenish. Understanding and fixing this issue is essential for perfect prints.

Common Hues Misinterpretation

At times, the color you see isn’t what you get. Sublimation relies on heat to transfer dye. This can alter the initial hue. For example, bright yellow may appear green after printing. Proper color profiling is essential for accuracy.

Factors Impacting Color Accuracy

Several elements can affect the outcome of a sublimated print. Here’s what to watch out for:

- Print Quality: High-resolution images prevent color blending.

- Heat Press Settings: Temperature and time must be precise.

- Sublimation Ink Quality: Invest in superior inks for true colors.

- Material: Certain fabrics react uniquely to sublimation dyes.

- ICC Profiles: These ensure color matching between devices.

| Issue | Cause | Solution |

|---|---|---|

| Color Shift | Incorrect Heat Press Settings | Adjust Temperature and Time |

| Poor Ink Quality | Using Cheap Inks | Switch to High-Quality Inks |

| Material Reaction | Material Not Compatible | Use Polyester or Polymer-Coated Items |

Adjusting these elements can lead to a significant improvement in color fidelity.

Science Behind Color Perception

How we perceive color can unlock mysteries in printing. At times, sublimation results might not match expectations. For example, a yellow that looks green could puzzle many. This phenomenon is rooted deep in the science of seeing. Light, material surfaces, and our brains work together to create color experiences.

Role Of Light And Material

Light plays a pivotal role in how colors appear. It interacts with materials, impacting color perception. Sublimated items might display color shifts due to this interaction.

- Light sources vary in color temperature.

- Materials reflect and absorb light differently.

- Sublimation ink reacts uniquely on different substrates.

Dye sublimation on differing materials may cause unexpected hues. For yellow turning green, the issue might lie here. Checking light sources and material properties can help.

Psychology Of Color

The brain interprets colors in ways that can influence emotion and perception. Yellow typically signifies happiness, while green might represent growth. This psychological aspect can affect how we process colors.

| Color | Positive Associations | Negative Associations |

|---|---|---|

| Yellow | Energy, Joy | Anxiety |

| Green | Growth, Harmony | Envy |

When yellow takes on a greenish tint, consider the surrounding colors. Also, check lighting that may influence interpretation. These factors together shape our color experience. Addressing color perception issues can help achieve true sublimation colors.

Sublimation Yellow’s Greenish Tinge

Imagine printing a vivid yellow, only to find it has a green hue. This puzzling outcome in sublimation printing can disappoint. Let’s dive into why sublimation yellow sometimes looks green. We will explore how to get that perfect sunshine-yellow back.

Chemical Composition Variables

Chemical factors play a vital role in sublimation colors. Ink quality and composition dramatically affect the final hue.

- Sublimation dyes: Not all dyes are equal. Poor quality means dull colors.

- Oxidation: Air exposure changes ink properties, leading to color shifts.

- OEM vs. third-party inks: Original inks typically yield truer colors.

Dye Substrate Interactions

The substrate also plays a key role. Fabric type and coating can alter perceived colors.

| Fabric Type | Color Shift |

|---|---|

| Polyester | True to color |

| Cotton | Not suitable for sublimation |

| Blend | Depends on polyester content |

Quality of coating: Substrates with uneven coatings can lead to color inconsistencies. Use items made for sublimation.

Heat press settings: Incorrect temperature and time can affect dye behavior.

Analyzing The Sublimation Process

Sublimation is a popular printing method, known for its high-quality and durable results. One common issue that might arise during the process is the yellow tint appearing green. Many variables affect the final color output. Properly managing these variables can solve this issue.

Temperature And Time Settings

Temperature and time are essential in sublimation printing. They affect color accuracy. Use these settings:

| Material | Temperature | Time |

|---|---|---|

| Polyester Fabric | 400°F | 45 seconds |

| Ceramic Mug | 385°F | 240 seconds |

Check the manufacturer’s guidelines for precise settings. Adjustments are sometimes necessary. Always test before final production.

Pressure And Humidity Effects

The right pressure ensures even heat distribution. This avoids color shifts in sublimated items.

- Use medium to high pressure on your press.

- Pressure should be consistent across the product.

- Uneven pressure leads to uneven coloration.

Humidity is another factor. High humidity impacts sublimation transfer.

- Keep your working environment between 45-70% humidity.

- Store sublimation paper in a dry place.

- Use a dehumidifier if necessary.

The right balance solves color issues, and results in accurate, vibrant prints.

Color Correction Techniques

Color Correction Techniques are essential in the world of sublimation printing. These techniques ensure your designs look perfect. Sometimes, sublimation yellow might look green. Yuck! But don’t worry. You can solve that! Let’s dive into how you can correct those colors and get stunning results.

Icc Profiles In Color Management

Digital colors need management, just like pets. ICC Profiles help with this. They are like translators for color. They make sure your printer and computer speak the same color language.

- ICC stands for International Color Consortium.

- Every printer has a unique ICC profile.

- These ICC profiles guide your printer to match the expected colors.

Using the right ICC profile is a game-changer. Make sure you pick the correct one for your printer and paper.

Test Printing And Iteration

Test printing is like a rehearsal before the big show. It allows you to fix issues before printing a lot.

Follow these steps for test printing:

- Print a small test design.

- Check if the colors match your expectations.

- Adjust printer settings if needed.

- Repeat the process until you get it right.

Each test gets you closer to perfection. Practice makes perfect, and that’s true for printing too!

Advanced Solutions For Color Matching

Advanced Solutions for Color Matching are crucial for achieving the perfect hues in sublimation printing. Sometimes, colors don’t turn out as expected. Yellow might look green. It’s frustrating, but no need to worry. We have robust solutions.

Industry-grade Equipment

To achieve precise color, the right tools are a must. Industry-grade equipment ensures colors print correctly. Let’s delve into what you’ll need:

- Sublimation Printer: High-quality printers produce accurate colors.

- Heat Press: Consistent heat transfer prevents color variation.

- Sublimation Dyes: Premium dyes yield pure, vibrant colors.

With these, sublimated items reflect true, vivid colors.

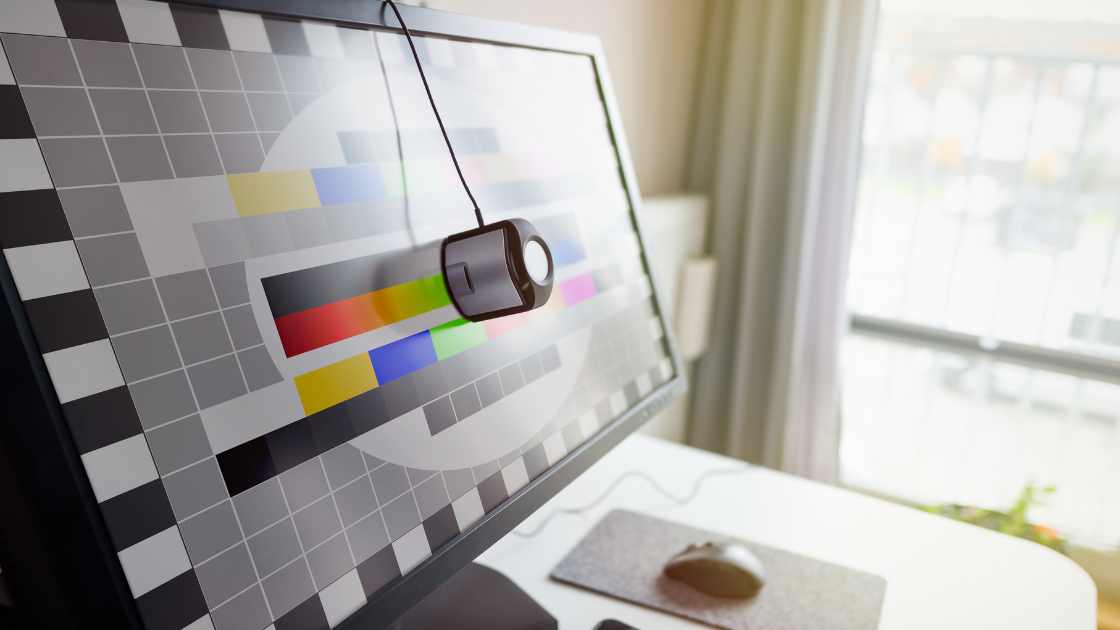

Software Calibration

Software calibration is a game-changer. It aligns output with design. Here’s how you can calibrate:

- Color Profiling: Create profiles for your devices.

- Monitor Calibration: Tools like colorimeters aid this process.

- Printer Settings: Adjust to match color profiles.

These steps help eliminate color discrepancies in prints.

| Problem | Solution |

|---|---|

| Yellow looks green | Adjust profile, recalibrate printer |

| Inconsistent colors | Use consistent heat and pressure in the heat press |

| Muddy colors | Ensure high-quality sublimation dyes |

Preventive Measures For Future Projects

Did colors play tricks on your last sublimation project? No worries. Let’s stop sublimation yellows from turning green for good.

Preventive measures are key for vivid, true-color future projects. Start with these steps:

Quality Control Best Practices

- Check your equipment. Dirty printers mean dirty colors.

- Test your inks. Quality inks give quality colors.

- Use correct profiles. Color profiles guide your printer.

- Monitor the heat press. Temperature affects the color output.

- Do a sample test. It helps catch color issues early.

Continuous Learning And Adaptation

- Stay updated with trends. Trends mean new techniques.

- Learn from mistakes. Each project teaches something new.

- Adjust with feedback. Customer insight improves results.

- Attend workshops. They equip you with cutting-edge skills.

- Read industry blogs. They offer fresh knowledge quickly.

Embrace these steps to keep your colors accurate. Your future sublimation projects will thank you

Frequently Asked Questions On Why Does Sublimation Yellow Look Green And How To Solve It

Why Is My Sublimation Looking Green?

Your sublimation might appear green due to incorrect color profiles or settings. Check your printer preferences, ink quality, and paper type to troubleshoot the issue. Ensure that your sublimation printer and software have the correct color management settings to resolve the color discrepancy.

Why Is My Yellow Cartridge Printing Green?

Your yellow cartridge may print green if it’s running low, the printhead is clogged, or there’s a color mixing issue. Check ink levels and run a cleaning cycle.

Why Is My Epson Sublimation Printer Printing Yellow Instead Of Green?

Your Epson sublimation printer may print yellow instead of green due to low ink levels, a clogged print head, or incorrect color settings. Check and replenish ink cartridges, perform a nozzle check, and adjust color management to your printing preferences.

How Do You Keep Sublimation From Turning Yellow?

To prevent sublimation from turning yellow, use proper time and temperature settings, choose high-quality sublimation ink and paper, ensure even heat distribution during pressing, store items and materials properly, and avoid prolonged exposure to UV light.

Why does my sublimation look green?

Why are my prints coming out green?

Conclusion

The science behind sublimation can be a game-changer for printing enthusiasts. Tackling the unexpected green hue in yellow prints starts with precise temperature control and high-quality inks. Embracing these troubleshooting tips will result in the vibrant, true-to-color transfers your projects deserve.

Remember, perfect prints are just a few tweaks away!