A DTF printer Won’t print White due to clogged nozzles or low ink levels. Solving the issue involves cleaning the head or replenishing the white ink.

Direct Film (DTF) printing offers a revolutionary approach to textile printing, allowing for vibrant designs on a myriad of fabrics.

Despite the innovation, encountering a hiccup like a printer failing to print white is not uncommon. This issue can stem from a range of factors, including ink system malfunctions or maintenance oversights.

Ensuring your DTF printer consistently delivers high-quality results involves regular cleaning routines and proper ink management.

Quick troubleshooting can often save time and reduce the frustration of halted production. Addressing the root causes promptly maintains the reliability and efficiency of your DTF printing operations, which is crucial for businesses aiming to deliver exceptional product quality in the competitive market of custom apparel.

Common Challenges With Dtf Printers

DTF printers revolutionized fabric printing with their ability to transfer designs to various materials.

Yet, these advanced machines face their own unique set of challenges. White ink, in particular, poses trouble for many users.

Proper maintenance and understanding of the printer can overcome these obstacles, restoring function to this essential color.

White Ink: The Stubborn Color

White ink tends to be more problematic than other colors. It’s thicker and requires regular agitation to prevent clogging.

Without this upkeep, white may refuse to print, leading to incomplete designs and wasted materials.

Regular troubleshooting and maintenance are crucial for peak performance.

Recognizing White Ink Issues

Recognizing the signs early can prevent further issues. Look out for missing elements in prints or faint colors.

Often, these are the first indicators of a clog or a malfunction. A simple checklist can help identify and tackle white ink challenges:

- Clogging: This is common due to white ink’s density. A cleaning cycle can sometimes fix this.

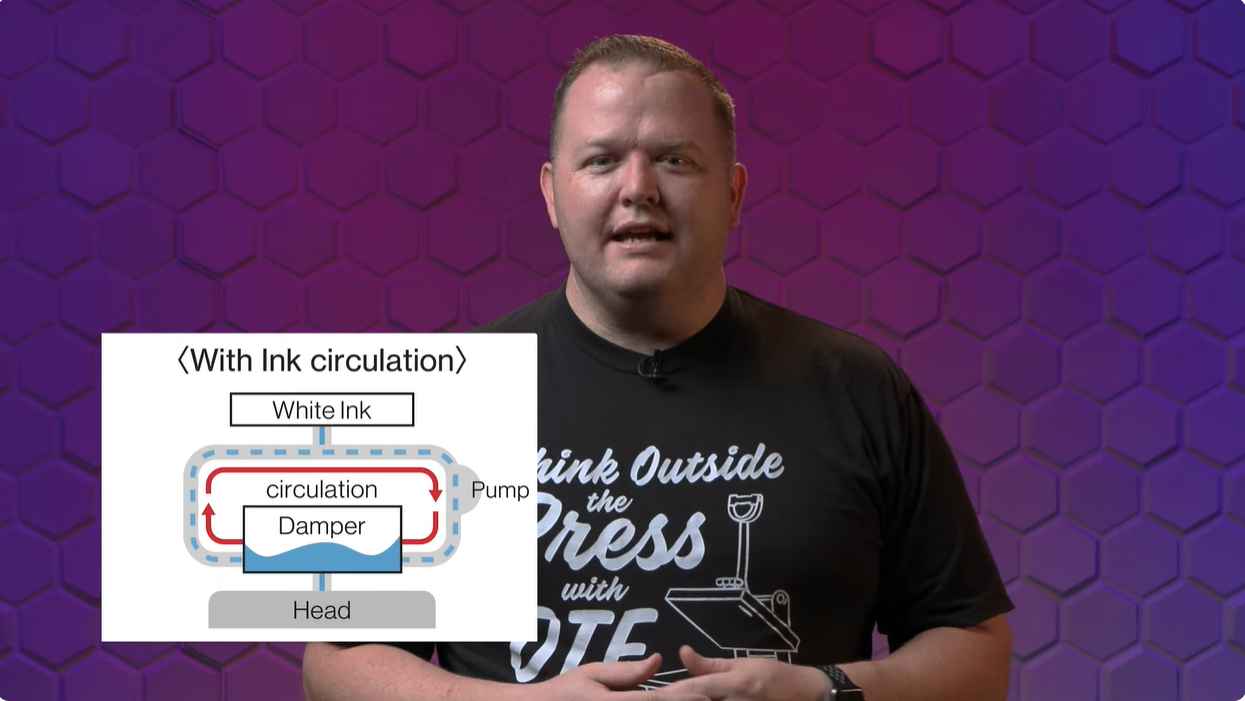

- Under or Over Circulation: Each printer has specific circulation needs. Check if these are met.

- Ink Sedimentation: If the white ink settles, shake the cartridge or stir the ink.

- Print Head Alignment: Misalignment can lead to white gaps. Run a head alignment check.

Follow the manufacturer’s instructions to clear these issues, keeping the white ink flowing and your prints perfect!

The Role Of White Ink In DTF Printing

The Role of White Ink in DTF Printing is pivotal for the creation of vibrant and long-lasting prints.

DTF, direct-to-film, is a popular printing technique that allows intricate designs on various fabrics.

But, when a DTF printer refuses to print white, it can put a halt to the entire process.

Understanding the significance of white ink and the common troubleshooting methods is essential for smooth operations.

White Ink Fundamentals

White ink acts as a foundation for the other colors in DTF printing. It provides a solid base layer that is crucial for transfers.

Without it, colors would lack vibrancy on darker fabrics. Here are white ink basics:

- Composition: White ink contains titanium dioxide (TiO2) to give it opacity.

- Consistency: It is typically thicker than other inks.

- Settling: White ink can settle in cartridges if not agitated regularly.

- Clogging: Prone to clogging print heads due to their thickness.

Why White Is Crucial For DTF Prints

Without white ink, DTF prints lose their impact. Let’s explore why white is key:

| Reason | Explanation |

|---|---|

| Visibility on Dark Fabrics | White ink allows designs to stand out on dark materials. |

| Color Accuracy | It ensures the true colors of the design are represented accurately. |

| Durability | A white base enhances the longevity of the print on the fabric. |

When a DTF printer fails to print white, several steps can be taken: perform regular maintenance, ensure proper ink levels, and check for software issues.

Periodically shake white ink cartridges to prevent settling. Clean the print heads to prevent clogs. Update the printer’s firmware and software.

Check that the design file is set up correctly, with the white layer in place for printing.

Identifying The Causes Of White Ink Failures

An essential issue that users of DTF printers face is the inability to print white ink.

Understanding the reasons why can help resolve this frustrating problem.

Under the subheading ‘Identifying the Causes of White Ink Failures’, let’s dig into the most common causes.

Clogged Nozzles And Their Effect

Clogged nozzles can lead to white ink not printing. When nozzles get clogged, printers can’t deliver ink properly.

- Ink drying in the nozzles.

- White ink has a high opacity, leading to solid particles that block nozzles.

- A maintenance routine is a must to prevent this.

Regular cleaning cycles are necessary to avoid clogged nozzles. Use the printer’s software to collect clean nozzles.

Check for a pattern break in the nozzle check print. This indicates a need for cleaning.

Ink Quality And Its Importance

White ink failures can also stem from the use of low-quality ink.

| Pigment Size | Effect on Printing |

|---|---|

| Large particles | More blockages |

| Too thin | Poor opacity |

Ensuring the right viscosity and particle size will keep the white ink running smoothly.

Storage conditions and shelf life affect ink quality. Always store ink bottles as directed by the manufacturer.

Using manufacturer-recommended inks can prevent many printing issues. Research and choose the best ink suited for your DTF printer.

Preventative Measures For White Ink Problems

Encountering issues with your DTF printer not printing white can be frustrating.

Understanding and preventing these problems before they occur is crucial.

By following routine maintenance and controlling the environment your printer operates in, you can keep your prints flawless and your white ink flowing smoothly. Here’s how to safeguard your DTF printer’s performance:

Routine Maintenance

Regular cleaning and upkeep are pivotal for preventing white ink mishaps in DTF printers.

White ink can be particularly prone to causing issues due to its unique composition.

It’s thicker and more pigmented, which means it can clog your printer’s components if not attended to.

Here are essential steps to include in your maintenance routine:

- Clean the print heads: Perform this at the end of each day.

- Flush the ink system: Do this weekly to prevent clogs.

- Update firmware: Keep your printer’s software up-to-date.

- Inspect cartridges: Check and shake them to maintain ink consistency.

The Right Environment For Your Printer

Not just maintenance, but also the environment plays a key role in white ink performance.

Your printer loves consistency. To create an ideal printing environment, consider these factors:

| Environment Factor | Optimal Condition |

|---|---|

| Temperature | Keep steady, ideally between 20°C and 25°C |

| Humidity | Maintain moderate levels, around 40%-60% |

| Dust levels | Minimize dust with clean work areas |

| Ventilation | Ensure good airflow to prevent ink solvent buildup |

By monitoring and adjusting these environmental factors, you promote optimal printer health and preempt many common white ink issues.

Troubleshooting Steps For Non-printing White Ink

Encountering issues with a DTF printer not printing white ink is a common hurdle for users.

The white layer is crucial for transfer quality, especially on dark fabrics. Thus, understanding how to troubleshoot this problem becomes essential for uninterrupted printing operations.

Follow these systematic steps to ensure the smooth functioning of your printer’s white ink capabilities.

Initial Checks And Balances

Begin with basic checks to diagnose the issue with white ink printing.

- Check Ink Levels: Verify if the printer has sufficient white ink.

- Inspect Cartridges: Ensure cartridges are correctly installed and secured.

- Nozzle Check: Perform a nozzle check to look for clogs or dried ink.

- Printhead Cleaning: Use the printer’s cleaning function to clear blocked nozzles.

- Ensure Proper Stirring: Some white inks need agitation to keep pigment from settling.

Advanced Diagnostics

Dive deeper if the initial steps don’t resolve the printing issue.

- Update Firmware: Check for printer firmware updates and apply if available.

- Check RIP Settings: Confirm the correct settings for white ink in your RIP software.

- Test Print Quality: Run a print quality test to identify any inconsistencies.

- Analyze Ink Tubes: Inspect for air bubbles or leaks in the ink tubes and connections.

- Contact Support: If issues persist, reach out to manufacturer support for assistance.

| Problem | Potential Cause | Solution |

|---|---|---|

| White Ink Not Printing | Low Ink Levels | Refill or replace white ink cartridges |

| Uneven White Output | Nozzle Clogging | Perform printhead cleaning cycles |

| Poor Quality Prints | Incorrect RIP Settings | Adjust white ink settings in RIP software |

Technical Solutions To White Ink Printing Dilemmas

Welcome to the troubleshooting realm of DTG printers where white ink refuses to make an appearance.

This guide dives into the technical solutions that bring back the missing hues. Don’t let white ink dilemmas dim your printing aspirations!

Printer Software Settings

Incorrect software settings can lead to white ink woes. Ensure your printing success with the right configurations. The steps below outline the process:

- Navigate to your printer’s software.

- Locate the ‘Ink Configuration’ section.

- Check the box for ‘White Ink’ options.

- Verify the ‘Underbase’ settings are active.

- Save changes and perform a test print.

It’s essential to confirm these on-screen steps with a physical test to solidify results.

Hardware Fixes

You might need to roll up your sleeves for these hands-on solutions. White ink can be needy; the tips below will keep it flowing.

- Inspect ink cartridges for white ink levels.

- Unclog any blocked nozzles with maintenance tools.

- Shake white ink cartridges to prevent pigment separation.

- Ensure the print head’s path is unobstructed.

- Double-check that the platen height is adjusted properly.

Practical hardware checks and tweaks can revive your prints. Your printer loves attention; a little care goes a long way in maintaining perfect prints!

Professional Advice On Managing Dtf Printer Ink

Professional Advice on Managing DTF Printer Ink is crucial for reliable operation and quality prints.

Direct to Film (DTF) printing technology relies heavily on the printer’s ability to handle white ink, which can create challenges.

Proper management and troubleshooting techniques can prevent common issues, such as a DTF printer not printing white ink.

Expert Tips

- Shake white ink cartridges regularly to prevent pigment settlement.

- Perform nozzle checks and cleaning cycles often to avoid clogging.

- Use high-quality DTF inks for consistent results.

- Maintain a regular printing schedule to keep inks flowing smoothly.

- Store inks in a cool, dark place when not in use.

When To Call A Technician

If the following issues arise, consider seeking professional help:

| Issue | Action |

|---|---|

| Consistent white ink nozzle blockages | Call a technician |

| Error messages related to the ink system | Call a technician |

| Poor print quality despite troubleshooting | Call a technician |

| White ink not printing at all | Call a technician |

Enhancing Long-term Printer Performance

Keeping your DTF printer in top shape ensures you’re always ready to create amazing prints.

A key issue like it not printing white can be a real roadblock. With consistent care, your printer can perform well for a long time.

Let’s dig into how to maintain that performance and address ink-related challenges.

Best Practices For Ink Management

Regular ink management is vital for your DTF printer’s health.

- Shake white ink cartridges daily to prevent sedimentation.

- Perform nozzle checks before large print jobs to detect issues.

- Ensure the ink levels are adequate and top off as needed.

- Use a circulation system if available to keep ink flow consistent.

- Clean the printhead and cap station regularly to avoid clogs.

Maintaining optimal temperature and humidity levels is crucial. Extreme conditions affect ink viscosity and printer performance.

Future-proofing Your DTF printer

Invest in your printer’s longevity with these steps:

| Strategy | Benefit |

|---|---|

| Use quality inks | Prevents printhead issues and maintains print quality. |

| Firmware updates | Ensures the latest features and fixes are at your disposal. |

| Regular servicing | Identifies potential problems early and extends printer life. |

| Replacement of parts | Avoids major failures and unplanned downtime. |

- Stay informed about new technologies and upgrade when beneficial.

- Train your team on proper printer operation and maintenance.

- Keep an emergency kit for quick fixes to common issues.

Frequently Asked Questions On Why DTF Printer Won’t Print White And How To Solve It

Why Is My DTF Printer Not Printing White?

One common issue is that the white ink may have settled if not used frequently. DTF printers require regular maintenance. To solve it, try shaking the white ink cartridges to mix the pigment and running a printhead cleaning cycle.

Can Clogged Nozzles Prevent White Ink Printing?

Clogged nozzles are a primary cause of printing issues in DTF printers. Performing regular nozzle checks and cleanings can help prevent and solve clogging, ensuring that white ink is dispensed properly during printing.

How Can Software Settings Affect White Ink Printing?

Incorrect software settings can prevent a DTF printer from printing white. Ensure that the white layer is enabled in the RIP software settings and that the design is set up correctly to print white where necessary.

What Are The Best Ways To Maintain White Ink Quality?

Proper maintenance includes using white ink regularly to prevent settling, storing ink at the right temperature, and shaking cartridges before use. Also, ensure the printer’s humidity levels are optimum for the ink.

Conclusion

Troubleshooting a DTF printer not printing white can be challenging. This post highlighted common issues and effective solutions. By following our steps, you can resolve printing problems and ensure vibrant, quality prints. Remember to maintain your printer regularly to minimize future disruptions.

Happy printing!