Sublimation black can sometimes look purple due to improper color management or ink formulation. To solve this, adjust printer settings and ensure accurate ICC profile usage.

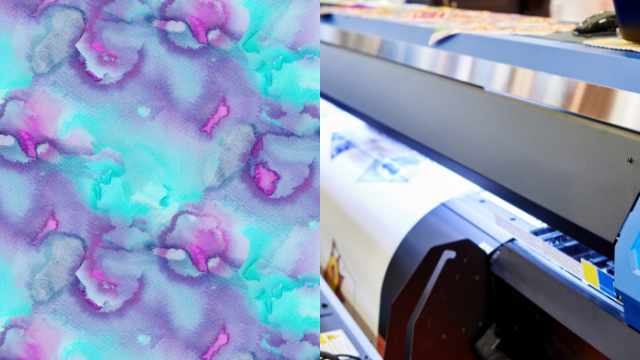

Sublimating items with a true black color is often essential for creating professional and high-quality products. One common issue in the sublimation printing process is black appearing purple, which can significantly impact the final appearance of a product.

This issue generally stems from the intricacies of color science and the way certain printers interpret color data.

In the realm of DIY printing and small-scale business production, grasping the intricacies of achieving the perfect black tone becomes paramount. For those wondering “Why Sublimation Black Looks Purple,” the key lies in implementing corrective measures.

This involves meticulously calibrating your printer, carefully choosing substrates, and opting for top-tier inks explicitly crafted for sublimation printing.

Masters of these techniques are better positioned to guarantee their creations not only meet but exceed customer expectations, establishing an enduring competitive advantage in the marketplace.

The Science Behind Sublimation Colors

Have you ever wondered why your sublimation black looks purple? It’s a common issue many encounter. But to solve the mystery, we must sink into the science of sublimation colors.

Color mishaps are not just mere annoyances. They disrupt the quality and aesthetics of your prints. Let’s unravel the science behind it and find solutions.

Sublimation Process And Ink Behavior

The sublimation process involves turning solid ink into gas without becoming liquid. This happens through heat.

When heat is applied to sublimation ink, it transforms into a gas. This gas bonds with polyester fabrics or polymer-coated items. But why do blacks turn purple?

It happens due to a mix of reasons:

- Ink Quality: Not all inks are equal. Some may lack the correct formulation.

- Heat Press Settings: High temperatures and incorrect timing affect ink behavior.

- Color Profiles: Digital settings need to match the ink’s properties for true colors.

Color Perception Variability

Colors are tricky. What we see might not be the actual color. Perception variability plays a role. Sublimation black can look purple due to:

- Light Source: Different light types can change how colors appear.

- Material Finish: Glossy or matte surfaces can shift perceived colors.

To fix color perception issues:

- Check the light under which you judge the printed colors.

- Use a consistent surface finish for accurate color reproduction.

Dissecting The Black-to-purple Phenomenon

Sublimation printing promises vibrant, long-lasting colors. Yet sometimes, black ink turns purple. Let’s uncover why and how to fix it.

Awareness Dye Behavior

Sublimation involves turning dye into gas to bond with fabric. This complex process can create color shifts.

Heat and pressure are essential for accurate color. Incorrect settings may alter black dye behavior, turning it purple.

Dye composition also affects color outcome. Quality dyes yield better blacks.

- Check your printer settings. Ensure optimal heat and pressure for true black.

- Use high-grade dye. Invest in quality sublimation dye for accurate colors.

The Role Of Fabric Type

Different fabrics react to sublimation dyes in unique ways. Polyester works best for vibrant blacks.

Coatings and blends can affect dye absorption. This can turn black into purple.

| Fabric Type | Black Quality |

|---|---|

| Pure Polyester | Best for true black |

| Poly-Blend | Can cause color shifts |

| Cotton | Not suitable for sublimation |

Choose fabrics wisely:

- Select 100% polyester for deep blacks.

- Avoid cotton as it won’t hold sublimation dye well.

- Test blends to find suitable options for your prints.

Common Factors Affecting Sublimation Outcomes

Sublimation printing is popular for its vibrant and durable results. Yet, sometimes the outcome isn’t perfect. A common issue is sublimation black looking purple. This becomes frustrating for many. The key to precise colors lies in the factors at play. Here, we will break down these factors and how they influence sublimation outcomes.

Printer Settings And Their Impact

Printer settings are crucial for sublimation success. A wrong setting can shift colors. Mainly, it affects how the design transfers onto the substrate. Correcting them ensures your blacks are truly black. Check for these settings:

- Color Management: Ensure proper color profiles are set.

- Resolution: High resolution prevents grainy images.

- Print Speed: Too fast can lead to insufficient color saturation.

Quality Of Sublimation Paper And Inks

The paper and inks you use are paramount. High-quality sublimation inks and paper make all the difference. Inks should be formulated for sublimation printing. Paper should be designed to release ink effectively.

| Type | Ink Quality | Paper Quality |

|---|---|---|

| Best | No color shift with a high transfer rate | Even ink release with a strong transfer |

| Average | Some color shifts and lower transfer rate | Inconsistent ink release |

| Poor | Color shift likely and low transfer rate | Uneven ink release and low transfer |

Heat Press Consistency Issues

Heat press consistency is another factor affecting sublimation. The heat must be evenly distributed. Temperature should be steady. Pressure should be uniform. This ensures that the sublimation ink turns to gas and transfers evenly, to avoid any color shifts like black turning purple.

- Temperature: Verify the heat press is at the correct temperature.

- Pressure: Adjust pressure settings to be consistent across the substrate.

- Time: Time your press accurately for a complete transfer.

Troubleshooting Purple Hues In Sublimated Blacks

Sublimation printing promises vibrant colors and crisp blacks. But sometimes, black comes out purple. Frustrating, right? This section helps fix that. Learn how to get true black back in your prints.

Calibrating Color Profiles

The colors look off sometimes. Color calibration is key. It tweaks how colors form. Follow these steps:

- Find your printer’s color management settings.

- Choose the correct color profile.

- Do test prints.

- Adjust settings as needed.

Software like Adobe Photoshop helps in calibration. Look for “Proof Setup” for a mockup of the final print. Consistent calibration ensures accurate colors.

Adjusting Heat Press Temperature And Time

Temperature and time affect sublimation. If blacks turn purple, check your heat press settings. Try these fixes:

| Incorrect Setting | Adjustment | Expected Outcome |

|---|---|---|

| Too High Temperature | Decrease by 5-10 degrees | Better color accuracy |

| Too Long Press Time | Decrease by 5-10 seconds | Reduce color bleeding |

Monitor changes closely. Small adjustments make big differences. Use a temperature gun for accuracy. Quality sublimation means precise control.

Best Practices For True Black Reproduction

Struggling to achieve true black in your sublimation prints? Often, what should be black turns out to look purple.

This common issue can frustrate any printing enthusiast but fear not. Let’s dip into best practices to ensure your prints come out with the deep, rich blacks you desire.

Pre-printing Fabric Treatment

To start, always treat your fabrics appropriately. Correct fabric preparation is vital for a true black.

- Choose high-quality substrate materials specifically designed for sublimation.

- Pre-treat the fabric with a sublimation primer to improve ink bonding and color accuracy.

- Ensure even coverage during pre-treatment to avoid color inconsistencies.

Profile And Ink Choices

Selecting the right profiles and inks plays a pivotal role in achieving true black in sublimation.

- Use a dedicated ICC profile for your printer and paper combination.

- Adjust your printer settings to increase the density of the black ink.

- Opt for high-quality sublimation inks that offer a deep and consistent black.

Experiment with different color management software to perfect your output. Remember, printer profiles are essential for the accurate reproduction of black on various fabrics.

Technological Innovations In Sublimation Printing

Technological Innovations in Sublimation Printing are changing the game. Experts know that sometimes sublimation black looks purple. Frustrating, right?

But why does it happen, and what can you do about it? The answers lie in the cutting-edge advancements in this field. Find how fresh ink formulas and modern machines tackle these challenges head-on.

Advances In Ink Formulations

Ink chemistry is an art and a science. Only the best inks give you true black without a purple tint. New ink recipes offer a richer, deeper black, designed just for sublimation. You no longer need to worry about colors that fade or change. These inks stay true to color even under heat.

- High pigment concentration ensures vivid colors.

- Vibrancy lasts through washes and wear.

- Made for consistency across many materials.

Cutting-edge Printers And Heat Presses

Printers and presses make or break sublimation success. Top-tier technology keeps heat and pressure just right. Say goodbye to purple blacks with gear that knows your needs. These tools assure precision and excellence every time.

| Feature | Benefit |

|---|---|

| Even Heat Distribution | Prevents color shift in prints. |

| Accurate Temperature Control | Keeps black ink from turning purple. |

| Consistent Pressure Application | Ensures even coloration. |

With these innovations, black in sublimation prints stay true. Equip yourself with these advancements to overcome the purple-black challenge. Transform every project into a masterpiece of color fidelity.

Expert Tips And Tricks For Sublimation Success

Sublimation printing often presents a unique challenge – black turning purple. It frustrates many beginners and experienced printers alike. Perfecting black in sublimation is essential for high-quality products. This section dives into expert insights to address this issue and to ensure sublimation success.

Learning From Industry Professionals

Industry professionals offer invaluable advice. They have overcome common printing obstacles, including ensuring true black color. Experience blends with technique, offering rich guidance on getting the colors right.

- Calibrating equipment is essential. Professionals suggest regular calibration of printers and heat presses.

- Using the correct ICC profiles ensures accurate color representation. Expert guides often include recommended settings.

Professionals also stress quality inks and papers. They note that sublimation-specific inks and transfer papers influence the final hues. It’s important to invest in these quality materials for consistent results.

One tip often passed down is adjusting the color balance in design software. Slight increases in yellow and decreases in magenta can prevent a purple hue in black.

Joining Communities And Forums For Support

Support from a community of sublimators is critical. Newcomers and seasoned printers benefit from collective knowledge online.

Forums and social media groups are treasure troves of information. Users share successes and help troubleshoot common issues like black appearing purple.

-

- Post questions and get answers from diverse experiences.

- Access to user-shared ICC profiles can improve color accuracy.

- Learn from tutorials and how-to guides posted by members.

Engaging with these communities encourages collaboration. Sharing experiences is beneficial. It leads to Finding new techniques, strategies, and solutions.

Frequently Asked Questions Of Why Sublimation Black Looks Purple And How To Solve It

Why Is My Black Sublimation Ink Printing Purple?

Your black sublimation ink may print purple due to an imbalance in the color profile, low-quality ink, or incorrect printer settings. Check your printer’s color management and use high-quality sublimation ink for accurate results.

Why Is My Sublimation Black Not As Black?

Your sublimation black may not appear true black due to a few reasons: incorrect color profile settings, low-quality sublimation ink, inadequate heat press temperature, insufficient pressing time, or the use of improper transfer paper. Adjusting these factors can improve the black intensity.

How Do You Fix Sublimation Colors?

To fix sublimation colors, adjust your printer settings for ink levels and paper type. Ensure you use high-quality sublimation ink and paper. Calibrate your printer regularly, and apply the correct heat press temperature and time. Use ICC profiles for accurate color reproduction.

How Do I Stop Sublimation From Shadowing?

To prevent sublimation shadowing, use a blowout paper, ensure proper pressure is applied, avoid shifting during pressing, pre-press your substrate, and choose high-quality inks and paper.

The black sublimation ink may be printing purple due to a color balance issue or a lack of black ink flow. Adjusting color settings in your printing software or ensuring proper ink levels and nozzle functionality could help resolve the problem.

Conclusion

The nuances of sublimation printing can improve your projects. Black turning purple is frustrating, but it’s fixable with the correct color profiles and printer settings. Implement the solutions discussed and you’ll see true black in your prints. Remember, patience and precision are key to sublimation success.

Keep experimenting to perfect your technique.