Yes, you can sublimate on silicone using specialized silicone sublimation blanks or coatings. Ensure you have heat-resistant tape and a sublimation printer ready.

Sublimation on silicone offers a unique opportunity to personalize and brand a vast array of silicone-based products. Crafters and business owners alike can now transfer vivid images onto silicone phone cases, wristbands, kitchenware, and more. Unlike traditional printing methods, sublimation embeds the ink into the silicone’s surface, providing durability and a professional finish.

To achieve this, you will need specific materials designed for silicone sublimation and a controlled heating process to ensure the best results. This technique is gaining popularity for its ability to produce long-lasting, full-color graphics on silicone items, which are often used in promotional merchandise and custom gifts. With the right approach, sublimating on silicone can be a straightforward and rewarding process.

Silicone Sublimation Basics

![]()

Sublimation on silicone blends science and art. This process allows for vibrant designs on silicone items. Understand the basics to start creating personalized silicone products. Let’s dig into what sublimation is and how silicone’s unique properties make it a suitable candidate for this creative adventure.

What Is Sublimation?

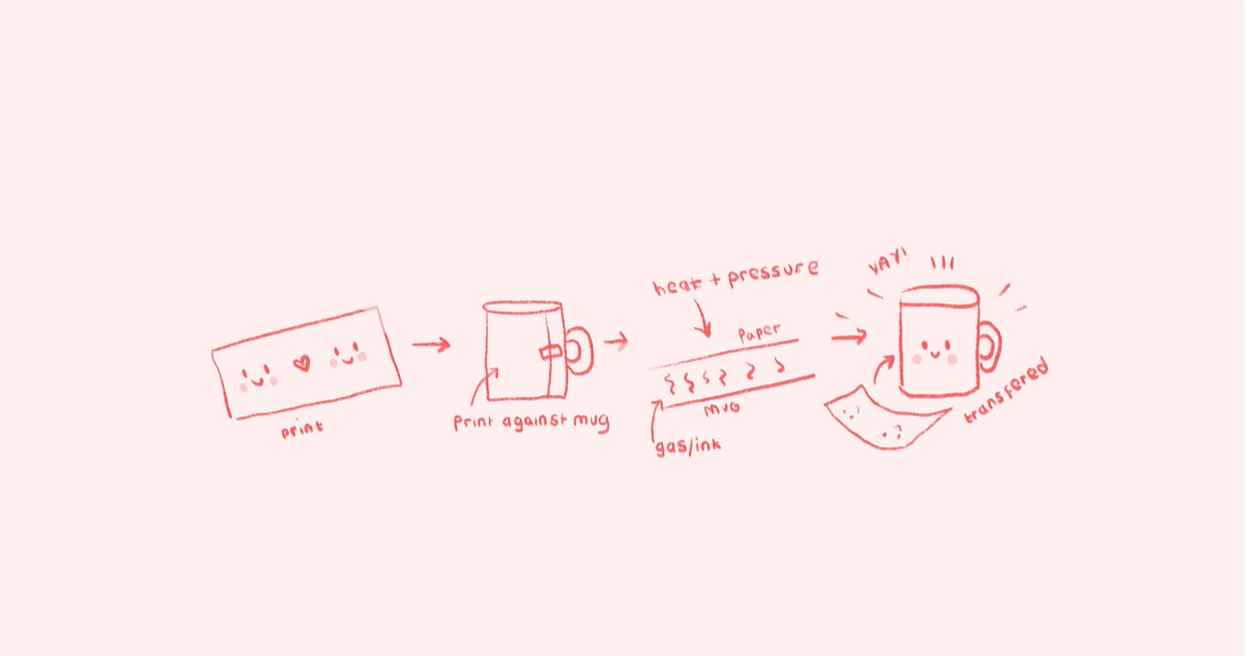

Sublimation is a printing technique. It turns solid dye into gas without becoming liquid. Heat and pressure apply this gas to materials. The result? Long-lasting, detailed images. This method works well on specially coated surfaces.

Properties Of Silicone

Silicone is a versatile material known for its durability and heat resistance. Its elasticity allows for easy application of designs. Silicone’s unique features enable it to accept sublimated ink under the right conditions. Essential properties include:

- Heat resistance: It withstands high temperatures required for sublimation.

- Elasticity: Molds to different shapes, important for sublimation products.

- Non-porous: A special coating is necessary for sublimation ink to adhere.

The sublimation method on silicone requires products coated for ink absorption. With the correct materials, create vivid, long-lasting prints on a variety of silicone products.

Sublimating on silicone opens a world of customization for various items. To start this creative journey, gather the essential tools first. Let’s explore each piece of equipment needed to sublimate designs onto silicone surfaces effectively. Remember, the right tools lead to the best results!

Types Of Sublimation Printers

Choosing a sublimation printer is your first step. Select a printer capable of handling sublimation ink. Here are the common types:

- Desktop Printers: Perfect for small projects or beginners.

- Wide-Format Printers: Ideal for larger prints and higher quantities.

Heat Press: Choosing The Right One

Silicone requires specific heat settings. A quality heat press makes all the difference. Look for the following features:

| Feature | Reason |

|---|---|

| Adjustable Temperature | Maintains precise heat for sublimation. |

| Timer | Ensures consistent pressing duration. |

| Even Pressure | Delivers uniform design transfers. |

Choose a press with a silicone pad for better results. This pad aids in distributing heat evenly across the surface. Proper equipment ensures a smooth sublimation process on silicone objects.

Prepping For Sublimation

Sublimating on silicone opens a door to endless creativity. Yet, prepping is critical for a flawless finish. This part of the process ensures that the ink bonds well. Consider it the foundation upon which vibrant, lasting designs are built.

Cleaning The Silicone Surface

Start with a clean canvas. Any dirt affects how the ink adheres. Follow these steps:

- Wipe the surface using a lint-free cloth.

- Use isopropyl alcohol to remove oils.

- Dry completely before the next step.

Applying Sublimation Coating

The coating is crucial for the sublimation process on silicon. This prepares the surface to receive the design. Take these actions:

- Choose a sublimation coating designed for silicone.

- Apply evenly across the surface.

- Allow the coating to dry thoroughly.

A smooth application means better design transfer.

The Sublimation Process Step-by-step

Sublimating on silicone blends science with creativity. This guide simplifies each step. Unlock the colorful potential of sublimation on silicone. Let’s dig in!

Image Printing And Trimming

Start with a high-quality image. Print it using sublimation ink and paper. Ensure the design mirrors your final desire. Get scissors or a cutter. Trim closely around your image. This step prevents excess ink transfer.

Heat Press Application

Time for heat. Place your image on the silicone. Use heat-resistant tape to secure it. Set the heat press. The temperature matters. Usually, it’s around 400°F (204°C). The pressing time varies. A general rule is 60 seconds. But check your product instructions.

Cooling And Peeling

After pressing, wait. Silicone gets hot! Let it cool. Patience ensures better adherence. Once cool, peel off the paper. Slow and steady wins. Your design should look vibrant! If not, check the temp and time used. Adjust as needed for next time.

Challenges And Solutions When Working With Silicone

Sublimating on silicone merges vibrant graphics with the durability of silicone products. But, like any specialized technique, it comes with its own set of challenges. Warping and ink smudging are common issues. Learn how to tackle these obstacles to achieve flawless results.

Dealing With Warping

Silicone can change shape at high temperatures. This is called warping. Keeping silicone flat is important during sublimation.

- Use a Heat-Resistant Mat: Place your silicone on a mat that can resist heat.

- Lower the Temperature: Try a cooler setting on your heat press.

- Shorten Press Time: Decrease the time your silicone is under heat.

Warping can ruin your design. With these solutions, you can sublimate silicone successfully.

Ink Smudging Issues

Sublimation ink can blur or smudge on silicone. This ruins the crispness of your graphics. Prevent ink smudges for a clean transfer.

- Clean the Surface: Wipe your silicone before pressing to remove oils or dust.

- Secure the Transfer: Use heat-resistant tape to hold the transfer in place.

- Test Press: Do a small test to adjust pressure and heat beforehand.

Clear images make products stand out. These tips help ensure vibrant, smudge-free designs.

Creative Ideas For Silicone Sublimation

Creative Ideas for Silicone Sublimation are taking customization to an extraordinary level. Sublimation on silicone allows for vibrant, long-lasting designs. Let’s find out some fantastic ways to apply this technique to unique items.

Personalized Phone Cases

Transform a plain phone case into a masterpiece with sublimation. Create unique designs that reflect personality.

- Favorite quotes

- Stunning artwork

- Personal photos

Choose bold colors for graphics to ensure they stand out. Consider the case’s shape to maximize the design impact.

Customized Kitchenware

Bring life to the kitchen with sublimated silicone kitchenware. Custom designs on spatulas, potholders, and baking mats add fun.

| Item | Idea |

|---|---|

| Spatulas | Food-themed patterns |

| Potholders | Bold statement designs |

| Baking Mats | Measurements and Guides |

Use heat-resistant sublimation ink to ensure the kitchenware survives high temperatures.

Sublimated silicone items merge vibrant designs with durability. Proper care ensures their longevity. This section shares key tips for maintaining sublimated silicone items.

Cleaning Tips

Keeping sublimated silicone items clean is straightforward. These simple steps will help maintain the vibrant prints.

- Use mild soap and warm water for routine cleaning.

- Avoid abrasive scrubbers that might damage the print.

- Do not use harsh chemicals such as acetone or bleach.

- Rinse thoroughly to remove all soap residues.

- Air-dry the items or use a soft cloth to prevent water spots.

Longevity And Durability

Sublimated silicone blends aesthetics with resilience. With care, these items can last for years. Remember these tips:

- Store in a cool, dry place away from direct sunlight.

- Avoid sharp objects that might cut or puncture the silicone.

- High heat can warp the shape, so keep away from open flames.

- Minimize exposure to oils and colored substances to prevent stains.

Frequently Asked Questions On Can You Sublimate On Silicone (yes, Here’s How)

Does Sublimation Work On Silicone?

Sublimation typically does not adhere well to silicone. Silicone lacks the necessary porous structure to absorb the sublimation ink effectively. To ensure a successful transfer, consider using specially coated silicone items designed for sublimation printing.

Can You Sublimate On Silicone Mats?

Yes, you can sublimate on silicone mats, provided they are coated with a sublimation-ready surface. Ensure the mat can withstand the high heat necessary for the sublimation process.

Can You Use A Silicone Mat For Heat Press?

Yes, you can use a silicone mat for a heat press to protect the material and evenly distribute heat during the pressing process.

What Can You Not Sublimate On?

You cannot sublimate on non-polyester fabrics, dark-colored materials, or non-coated rigid substrates. Sublimation requires polymer-based surfaces to ensure the ink properly transfers and adheres.

Conclusion

Sublimating on silicone is not only possible, it’s an exciting way to personalize a wide array of products. By following the steps outlined in this post, you can achieve vibrant, long-lasting prints. Adopt the challenge and unlock the creative possibilities with your silicone sublimation projects.

Happy printing!