Sublimate on Viscose is generally not recommended as the fabric may not correctly bind with the sublimation dye. Viscose lacks the required polymer fibers to ensure a vibrant and lasting transfer.

Exploring the nuances of fabric printing reveals various techniques suited to different materials. Sublimation printing is a popular method known for its durability and high-quality results, especially on synthetic fabrics like polyester. Viscose, commonly known as rayon, presents a challenge for sublimation due to its semi-synthetic nature, derived from cellulose.

This fabric typically fails to hold the sublimation ink, leading to faded and unsatisfactory prints. Crafting enthusiasts and businesses often seek alternative methods for decorating viscose, such as traditional screen printing or utilizing specialized inks designed to adhere better to this kind of material.

Mastering the limitations and compatibility of sublimation with different textiles ensures successful and attractive printing outcomes.

The Basics Of Sublimation Printing

The Basics of Sublimation Printing opens up a colorful world of creativity and customization for fabrics and products. This printing method embeds ink into materials, producing vivid images that stand the test of time.

Essence Of Sublimation Process

Sublimation printing transforms a solid into a gas without a liquid phase. Special printers and transfer papers team up with heat presses. Together, they bond the ink with the material. The result? Durable designs that resist fading and cracking.

- Design printed on sublimation paper

- Heat press applies high temperature and pressure

- Ink turns into gas, penetrating the material

- Cooling solidifies the ink within the fabric

Materials Compatible For Sublimation

Sublimation thrives on polymer or polyester-based fabrics. Not all materials take kindly to sublimation, though. Let’s explore if viscose, a unique material, is suitable.

| Material Type | Sublimation Friendly |

|---|---|

| Polyester | Yes |

| Cotton | No |

| Viscose | Partial |

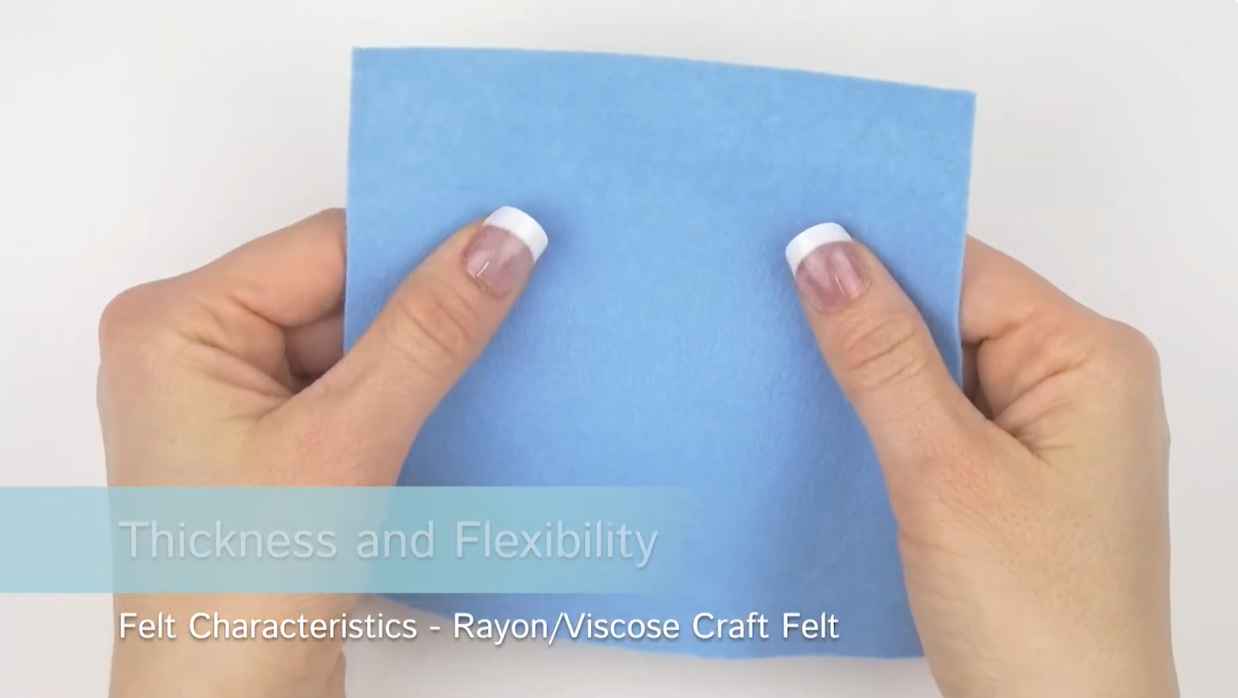

Characteristics Of Viscose Fabric

Characteristics of Viscose Fabric often spark curiosity among enthusiasts and professionals alike. This unique material blends natural and synthetic qualities, making it versatile for many applications. Discover how the origins and composition contribute to its distinct textile qualities and uses.

Origins And Composition

Viscose, also known as rayon, emerges from regenerated cellulose fiber. Manufacturers create this fiber by dissolving cellulose, often from wood pulp, and then spinning it into yarn. The result? A semi-synthetic fabric with a silky feel and appearance.

| Component | Source | Process |

|---|---|---|

| Cellulose | Wood Pulp | Chemical Solution |

| Yarn | Cellulose | Spinning |

Textile Qualities And Uses

- Softness: Slightly cool to the touch, similar to cotton

- Draping: Excellent draping quality that mimics silk

- Absorption: High moisture absorbency, ideal for summer wear

Viscose fabric boasts flexibility in use. Its widespread applications range from clothing such as dresses and blouses to home textiles like bed linens and curtains. Durability mixed with luxury makes viscose a popular choice in fashion and interior design.

Challenges With Sublimating On Viscose

Challenges with Sublimating on Viscose arise due to the unique characteristics of the textile. Sublimation is a popular technique for printing vibrant designs. Viscose, however, presents a few obstacles that need careful consideration to achieve quality results. Understanding these challenges is important for success.

Heat Sensitivity Concerns

Viscose fibers are known for their low heat tolerance. This can lead to several problems when applying the high temperatures needed for sublimation:

- Shrinkage: A common issue where the fabric dimensions are reduced, affecting the fit and look.

- Scorching: Excessive heat may burn the fibers, leaving permanent marks.

- Loss of Softness: Heat can stiffen the naturally soft feel of viscose.

Ink Absorption And Dye Migration

Sublimation ink interacts differently with viscose compared to polyester. Key absorption and migration challenges include:

- Poor Ink Transfer: Viscose may not absorb sublimation inks as efficiently as synthetic fibers.

- Blurred Images: Inks might spread beyond borders, leading to fuzzy designs.

- Color Shift: Dye migration can cause unintended color changes after heat pressing.

Prepping Viscose For Sublimation

Enhancing the quality of your sublimation prints on viscose starts with effective preparation. Proper prepping ensures vibrant and enduring designs. Let’s dig into techniques that ready viscose for sublimation.

Surface Treatment Methods

Before sublimating on viscose, the fabric must undergo specific treatments to accept dye better. These methods range from simple to complex, each affecting print quality.

- Coating Application: Apply a polymer coating to create a receptive layer.

- Heat Pressing: Pre-press the fabric to remove moisture and wrinkles.

- Temperature Control: Maintain constant heat for even dye absorption.

Pre-printing Techniques

Implementing pre-printing strategies significantly improves sublimation outcomes on viscose. These practices help ensure a flawless transition of your design onto the fabric.

- Image Quality: Use high-resolution images for sharp, clear prints.

- Test Printing: Conduct a trial run on a similar fabric to gauge color accuracy.

- Mirror Image: Always flip your design horizontally before printing.

Step-by-step Guide To Sublimation On Viscose

Ready to freshen up your wardrobe with custom prints? Sublimation on viscose adds vibrant patterns to your clothes. Follow this guide to create stunning designs on viscose fabrics.

Heat Press Settings

Achieving the perfect print begins with the correct heat press settings. Here’s what to do:

- Set the temperature to 375°F (190°C).

- The time should be 40 seconds.

- Pressure must be medium to high.

Always do a test print first. This ensures your settings are just right.

Post-printing Processes

Once printed, handle the fabric with care. Follow these steps:

- Let the print cool down completely.

- Carefully peel off the paper.

- To fix the dye, heat press again for 30 seconds.

Washing is important to remove excess ink. Use cold water and a gentle cycle.

Welcome to the vibrant world of fabric printing where sublimation on viscose unlocks a world of brilliant colors and sharp designs! Achieving high-quality sublimation results involves a blend of skill, the right materials, and keen attention to detail. Let’s find some essential tips to ensure your viscose fabrics come out looking immaculate.

Choice Of Inks And Papers

Sublimation is a game of precision, where the choice of inks and papers plays a pivotal role:

- Select inks specifically formulated for sublimation. Their composition ensures a flawless transfer.

- Opt for high-release sublimation papers. These papers ensure that you get the most vibrant colors.

- Remember, compatibility between your inks and paper affects the final output. Check for recommended pairings.

Preventive Measures For Common Issues

To sidestep common sublimation pitfalls, follow these preventative strategies:

- Ghosting: Secure the fabric and paper together with heat-resistant tape to avoid slight image shifts.

- Fading: Choose viscose blends that can withstand the heat and maintain color integrity.

- Moisture: Pre-press the fabric to eliminate moisture which can lead to unwanted color splotches.

| Step | Action | Expected Result |

|---|---|---|

| 1 | Test your ink and paper compatibility. | Enhanced color output |

| 2 | Pre-press to remove moisture. | Sharper image quality |

| 3 | Use heat-resistant tape during pressing. | No ghosting |

Innovative Alternatives And Blends

Finding the perfect material for sublimation printing can be a challenge. Traditional cotton doesn’t hold the dye well, and pure polyester can feel less natural. Enter viscose, a semi-synthetic fiber known for its silk-like feel and high-quality print results. This section digs into how you can optimize the potential of viscose for sublimation printing through innovative alternatives and blends that balance quality and practicality.

Using Viscose Mixes

When you blend viscose with other fibers, new doors open for sublimation printing. These mixes combine the best of both worlds: the printability of synthetic fibers and the comfort of viscose. Here are some common blends and their benefits:

- Viscose-Polyester: Improves print clarity and color vibrancy.

- Viscose-Cotton: Offers a softer touch with better print retention than pure cotton.

- Viscose-Spandex: Adds stretch while maintaining print quality.

Careful selection of the blend ratio is crucial to get the desired result. For instance, a higher percentage of polyester might be better for vibrant prints, while more viscose can provide a softer feel.

Emerging Technologies In Fabric Printing

The textile industry is constantly evolving, and so are the techniques for printing. New technologies aim to improve the results of sublimation on viscose and its blends:

| Technology | Advantages |

|---|---|

| Digital Direct-to-Garment (DTG) | Allows for precise and vibrant printing on viscose blends. |

| Nano-Sublimation | Improves ink penetration for long-lasting prints. |

| Hybrid Printing Methods | Combines different printing techniques for optimal results on mixed fabrics. |

These emerging technologies are expanding the possibilities for sublimating viscose, making it easier to achieve high-quality, durable designs.

Frequently Asked Questions Of Can You Sublimate On Viscose

Can You Print On Viscose Fabric?

Yes, you can print on viscose fabric using specific inks and printing techniques suitable for delicate fibers.

What Materials Can You Not Sublimate On?

Sublimation does not work on 100% cotton, non-polymer-coated metals, natural fabrics, and dark-colored materials. Only light-colored, polyester-rich surfaces are suitable for sublimation.

What Fabrics Can You Sublimate On?

You can sublimate on polyester or polymer-coated fabrics. Blends with high polyester content also work well, ideally over 65% for vivid colors.

Can you sublimate on silk fabric?

Certainly! “Exploring the Art of Silk Sublimation: Unveiling the intricate process and creative possibilities of sublimating on silk fabric, this article delves into the unique challenges and stunning outcomes that arise when marrying this delicate material with the vibrant world of sublimation printing.

Can you sublimate on microfiber material?

Exploring the Art of Sublimation on Microfiber: A comprehensive investigation into the feasibility and techniques of sublimating vibrant designs onto microfiber materials, unlocking new possibilities for customization and creativity in textile applications.

Can You Sublimate On 50% Polyester 25% Cotton 25% Rayon?

Yes, you can sublimate on a blend of 50% polyester, 25% cotton, and 25% rayon, but the print may not be as vibrant or durable as on 100% polyester.

Conclusion

Sublimating on viscose offers creative possibilities but demands caution. Perfect your technique to prevent fabric damage and ensure vibrant results. Always test first and choose the right inks and heat settings. With these tips, your viscose garments can transform into personalized works of art.

Adopt the challenge and let your designs shine.