Yes, a heat press can catch on fire if it is improperly used or maintained. It is essential to follow safety protocols to prevent such hazards.

Heat presses, widely utilized for printing designs onto various materials, carry inherent risks if not operated with caution. These machines generate high temperatures and require diligent oversight. Ensuring electrical components are in good working order and not leaving the heat press unsupervised while it’s hot are critical safety measures.

We will explore about “Can a Heat Press Catch on Fire?” Regular maintenance is essential to prevent overheating and potential fires. Operators must fully grasp their heat press’s manual and follow all safety guidelines.

While user-friendly, a heat press requires respect for its operational heat to mitigate fire risks and ensure a secure working environment. Prioritizing safety allows businesses and hobbyists to use these machines confidently, free from fear of fire-related incidents.

The Basics Of Heat Press Operation

Exploring the world of heat pressing reveals a simple truth: understanding your tools is key. Fully grasping the basics of heat press operation is the first step in creating high-quality prints safely. Now, let’s dive into the components that make a heat press function and the typical scenarios in which they’re used.

Components And Design

Every heat press machine includes several vital parts. These components prevents accidents and ensures top performance:

- Platen: The heated plate that applies pressure and temperature to the material.

- Heat Element: Generates the heat that’s essential to the transfer process.

- Temperature Controller: Manages the heat level to avoid overheating.

- Timer: Monitors the duration of heat application.

- Pressure Adjustment: Regulates the force exerted by the platen.

Quality design ensures these components work in harmony. Experts choose machines with precise controls and even heat distribution for the best results. Well-made heat presses also come with safety features to minimize fire risks.

Typical Usage Scenarios

Heat presses serve various purposes, from business to hobby use:

- Custom T-shirt Printing: A common use for applying designs onto fabrics.

- Creating Merchandise: Ideal for producing custom bags, hats, and mugs.

- Sublimation Printing: Used to transfer complex images onto polyester items.

Each scenario requires different settings. Users must follow manufacturer guidelines to prevent overheating. Regular maintenance and proper operation are very important. These preventative measures keep the heat press in good working condition and reduce the risk of fire.

Potential Fire Hazards In Heat Presses

Heat presses work at high temperatures to transfer designs onto materials. Like any high-heat appliance, they have fire risks. Knowing these risks keeps users safe. Let’s discuss common hazards associated with heat presses.

Electrical Malfunction Risks

Heat presses require steady electricity to operate. Poor wiring or faulty equipment can lead to malfunctions. Here are some risks:

- Short circuits: Exposed wires may cause sparks.

- Frayed cords: Worn-out cables can ignite.

- Power surges: Unexpected voltage can damage circuits.

Prevent these by regularly inspecting for cord damage and using surge protectors.

Overheating And Material Ignition

Leaving a heat press on for too long can lead to overheating. Materials inside may catch fire. To prevent this:

- Do not exceed recommended temperatures.

- Use heat-resistant platen covers.

- Never leave the heat press unattended.

Always follow the manufacturer’s guidelines for temperature settings and usage times.

Preventing Heat Press Fires

When it comes to heat press equipment, safety is a top priority. These devices reach high temperatures and are used frequently in various industries, including custom t-shirt printing and manufacturing. It’s actual to acknowledge that without proper attention, there is a risk of fire. However, implementing preventative measures can significantly reduce this risk. Below, we outline essential strategies for preventing heat press fires.

Regular Maintenance Routines

Maintaining your heat press is vital for safe operation. Follow these steps:

- Check the electrical cords for wear and tear.

- Inspect the heat platen for any signs of damage.

- Clean the heat press regularly to prevent buildup.

- Ensure all components are functioning correctly.

| Maintenance Task | Frequency |

|---|---|

| Inspection of Electrical Components | Monthly |

| Surface Cleaning | Weekly |

| Hardware Check (Screws, Knobs) | Bi-Weekly |

Safe Operational Practices

To maintain safe operation, adopt these practices:

- Never leave the heat press unattended while on.

- Use heat press machines on a stable surface.

- Train staff on proper usage and safety protocols.

- Keep flammable materials away from the machine.

By diligently following these guidelines, you can operate a heat press more safely and help prevent accidents. Regular check-ups and careful use are the keys to long-lasting, safe equipment.

Real-life Incidents Of Heat Press Fires

Think heat presses are all safe and sound? Think again. Real-life incidents of these devices catching fire aren’t just Hollywood drama – they happen in the real world.

Case Studies Analysis

Let’s delve into actual cases where heat presses sparked disaster:

- Small Business Blaze: A boutique’s heat press left on overnight turned a dream into ashes.

- School Scare: Students watched in horror as a malfunctioning press ignited during class.

- Home Hazard: A crafting enthusiast’s heat press turned her workspace into a fire zone.

Learnings From Past Accidents

What have we learned from these fiery incidents?

| Incident | Key Learning |

|---|---|

| Small Business Blaze | Never leave heat presses on unattended. |

| School Scare | Regular maintenance is a must. |

| Home Hazard | Keep flammable materials away from heat presses. |

Stay alert, follow safety protocols, and remember these past accidents to keep your press and premises fire-free.

The Risks: Heat Press Temperatures

Heat Press Temperatures is critical for safe operation. A heat press machine applies heat and pressure to transfer designs onto materials. Wrong temperatures might risk starting a fire. This section explores safe heat press usage and material-specific temperature thresholds.

Temperature Thresholds For Common Materials

Each material has a safe temperature range. Stay within limits to prevent overheating.

| Material | Temperature Range (°F) |

|---|---|

| Cotton | 380-430 |

| Polyester | 270-300 |

| Nylon | 270-300 |

| Spandex | 320-340 |

Follow manufacturer guidelines for exact temperatures. Adjustments may be necessary for different thicknesses or blends.

Managing High-temperature Settings

Prevent overheating by managing settings properly. High temperatures require close attention.

- Set timers for safety

- Use thermal tape for added security

- Never leave the press unattended

- Regularly check the device for wear and tear

Regular maintenance can detect issues before they cause harm. Always turn off the heat press when not in use.

By understanding material limits and managing settings, you reduce fire risks significantly.

Proper Ventilation And Workspace Safety

Proper Ventilation and Workspace Safety are awareness of any environment where heat-producing equipment is in use. This truth holds firmly for those utilizing heat presses. These powerful machines generate high temperatures that can pose fire risks. By focusing on ventilation and workspace layout, the chance of a heat press catching fire diminishes greatly. Let’s dive into the best practices for maximizing safety and minimizing risks.

Workspace Layout For Fire Prevention

Designing the layout of a workspace with fire safety in mind is key. Keep the heat press in a clear zone with no flammable materials nearby. Here are essential pointers for a safe workspace:

- Distance – Ensure the heat press stands away from walls and other equipment.

- Cleanliness – A tidy area prevents the accumulation of flammable detritus.

- Accessibility – Have a fire extinguisher within easy reach at all times.

- Inspection – Regularly check wires and electrical outlets for wear and tear.

Importance Of Adequate Airflow

A well-ventilated space is not just comfortable; it’s a matter of safety. Heat presses should operate in areas with good airflow. Here’s why:

- Heat Dissipation – Adequate airflow helps disperse heat evenly, preventing hotspots.

- Ventilation – It minimizes the buildup of fumes that can be hazardous when inhaled.

- Equipment Longevity – Cooler operating conditions ensure your machines last longer.

Use an HVAC system or fans to maintain constant air movement. Remember, good airflow contributes significantly to workspace safety.

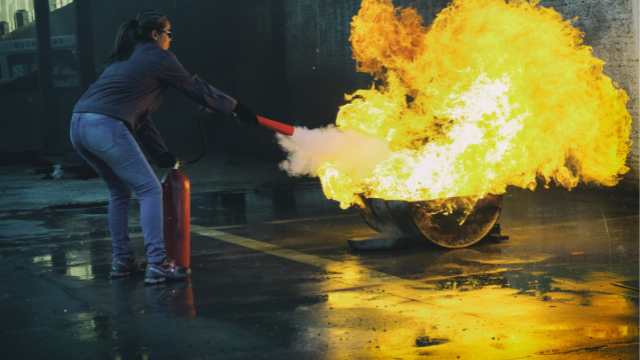

What To Do In Case Of A Heat Press Fire

A heat press act swiftly in the event of a heat press fire could save lives and property. It’s insight to stay calm and know what steps to take. Familiarize yourself with these strategies to keep your workplace safe.

Fire Extinguishing Techniques

Confronting a small fire requires quick action.

Always keep an extinguisher nearby. Check it often to make sure it works. Know how to use it.

- Turn off the heat press immediately.

- Pull the extinguisher’s pin.

- Aim at the fire’s base, not the flames.

- Squeeze the handle and sweep side to side.

Never use water on electrical fires. This can make things worse. If the fire grows, get out fast.

Emergency Response Plan

Having an emergency plan is key. Make sure everyone knows it well.

- Evacuate the area immediately.

- Call emergency services.

- Gather at the planned meeting spot.

- Count everyone to ensure all are safe.

Practice the plan often. This can save precious time in a real emergency.

Advancements In Heat Press Technology For Safety

Heat presses are necessary tools for custom apparel creation. In the past, these machines posed a fire hazard if misused or left unattended. Recent technological advancements focus on enhancing safety, reducing risks, and providing peace of mind for users.

Innovations Reducing Fire Risk

Modern heat presses come with several innovations to mitigate the risk of fire. These safety features include:

- Automatic Shutoff: This function powers down the machine when inactive for a predetermined period, preventing overheating.

- Temperature Controls: Precise digital thermostats maintain consistent heat levels, reducing the chance of material ignition.

- Flame-Retardant Materials: Components are now often built with materials that resist flames and heat, limiting fire hazards.

Future Outlook On Heat Press Safety Features

The future of heat press technology promises even greater safety enhancements. Innovators continue to research and develop features such as:

| Feature | Description | Expected Benefits |

|---|---|---|

| Smart Sensors | Monitor pressure and heat distribution | Prevent overheating and material damage |

| Enhanced Auto Shutoff | More sensitive and quicker response times | Immediate action against potential fire risks |

| Integrated Fire Suppression | Systems to extinguish fires quickly | Extra layer of protection during operation |

These safety features not only protect users but also extend the life of the heat press machines.

Frequently Asked Questions On Can A Heat Press Catch On Fire

Is A Heat Press Fire Hazard Common?

Heat press machines carry a minimal fire risk when used correctly. However, leaving them unattended at high temperatures or ignoring maintenance can increase fire risks. It’s sensitive to follow the manufacturer’s instructions and safety guidelines to prevent such hazards.

What Causes Heat Press Machines To Ignite?

Overheating is the primary cause of heat press ignition. This can occur due to malfunctioning thermostats, electrical issues, flammable materials nearby, or prolonged use without proper cooling periods. Regular inspection and careful operation can mitigate these risks.

Can Faulty Wiring Cause A Heat Press To Catch Fire?

Yes, faulty wiring can lead to electrical fires in heat press machines. Damaged cords or improper electrical connections can cause short circuits. Ensuring good wiring condition and using a surge protector can help prevent electrical fire incidents.

Do Heat Press Temperature Settings Affect Fire Risk?

High temperature settings can amplify the fire risk if a heat press is left unsupervised or in use for extended periods. It’s important to use the correct temperature for your material and to monitor the heat press during operation.

Conclusion

The fire risks associated with heat presses is for safety and property protection. By following manufacturer guidelines and maintaining equipment, risks can be minimized. Regular inspections and a clean workspace are essential. Stay vigilant and enjoy crafting with peace of mind, knowing you’ve taken the right precautions.